BETE Spray Nozzles by Spray Pattern

Browse BETE Spray Nozzles by Spray Pattern including Fan, Full Cone, Full Cone Spiral, Hollow Cone, Misting, Straight Jet, Tank Washing and the

NEW HydroPulse® Electrically Actuated Precision Spray Nozzles and FlexFlow™ Precision Spray Control Systems for Automatic Spray Nozzles.

|

Full Cone | Hollow Cone | Flat Fan – Electrically Actuated Precision Spray NozzlesHydroPulse® Electrically Actuated Automatic Precision Spray Nozzles BETE Electric-Actuated HydroPulse® Spray Nozzles (EHPI) assure precision volumes of expensive ingredients and compounds are sprayed directly onto your processing target, with overspray waste virtually eliminated. Pair with the BETE FlexFlow™ Precision Spray Control System to achieve uniform coverage, even if you adjust your conveyor speed. BETE’s Hygienic Electric HydroPulse® is the recommended solution for precision Food Processing applications. Learn More Hydro-Pulse® Food-Grade Electrically Actuated Automatic Precision Spray Nozzles FlexFlow™ Precision Spray Control System for Automatic Spray Nozzles VIDEO: BETE Electric HydroPulse® Automatic Precision Spray Nozzles – Hi-Speed Video Spray Demonstration

|

|---|---|

|

Air Atomizing Spray NozzlesAir atomizing nozzles atomize fluids by creating a very fine spray. Liquid and compressed air (gas) are used to produce a mist of atomized liquid at low pressures. Air atomizing is ideal for:

The following nozzles are Air Atomizing Spray Nozzles

|

|

Flat Fan Spray NozzlesFlat Fan nozzles are hydraulically driven and produce a flat fan pattern one of two ways. The nozzle either has an angled cut or a sloping deflection face to create the fan spray pattern. BETE has years of experience with innovative spray nozzle design and manufacturing. That knowledge combined with your process expertise, means cutting-edge solutions to industry demands. The following direct pressure nozzles produce a flat fan spray pattern:

|

|

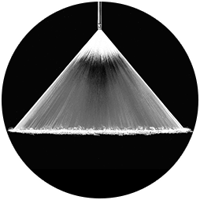

Full Cone NozzlesThe most commonly used nozzle type in industry is the Full Cone nozzle. The nozzle emits spray in a conical shape by dispersing liquid over the cone’s interior. When the spray meets with a surface, a circle of spray is created with liquid present throughout. The following nozzles produce a conical spray pattern:

How is this spray pattern achieved through nozzle design? WL, MPL, MP, CW, SC, NC, NCS, NCK, NCFL and TC series: for these Full Cone nozzles, the pattern is achieved by way of an internal vane. The water passes through this vane, and because of the angular passageways, the liquid starts to spin. The spinning creates a centrifugal force exerted upon the geometry of the exit creating the spray pattern. WTZ and TSC: for these Tangential Full Cone nozzles, the spray pattern is achieved by introducing the liquid into the body of the nozzle by way of a slight angle so the liquid swirls around the body cavity before exiting the orifice. In order to create a full cone version of the tangential set up, one wall of the nozzle with fins disrupts the swirling of the liquid and directs it toward the center of the orifice. |

|

Full Cone Spiral NozzlesThe full cone pattern from a spiral nozzle consists of several concentric hollow cones that join to produce a full cone effect with a smaller droplet size. The TFXP and STXP nozzles offer a larger free passage by stretching out the helix (spaces between the spiral turns) and providing the nozzle a free passage of at least the orifice diameter. The N Series is offered with FM and UL Approvals for sensitive Fire Protection applications. The following nozzles produce this spray pattern:

How is this spray pattern achieved through nozzle design? A spiral helix directs the liquid after it leaves the orifice. Each spiral turn allows for a different spray angle, thus creating a full cone nozzle. |

|

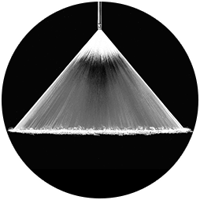

Hollow Cone NozzlesA hollow cone nozzle sprays fluids in a ring-like pattern around a given radius. Hollow cone nozzles produce a good interface between air and the surface of the droplets. When you require a small droplet size with capacity, these nozzles fill the bill. Tangential hollow cone nozzles are perfect for low clearances when a pattern needs to be directed 90° from the inlet. The following nozzles produce this spray pattern:

How is this spray pattern achieved through nozzle design? Tangential Whirl: Tangential hollow cone nozzles utilize a supply of liquid perpendicular to the direction of spray. Flow enters a swirl chamber without the use of internal components — allowing for maximum clog resistance. Whirl nozzles: Whirl hollow cone nozzles supply axially to the spray. The inlet of the nozzle and direction of the spray are inline. Flow enters the nozzle and is directed by channels or vanes to swirl along the axis of the nozzle. The emitting spray is atomized in a hollow cone pattern. Spiral Nozzles: Spiral hollow cone nozzles also supply axially to the spray. The inlet of the nozzle and direction of the spray are inline. Flow enters the nozzle and is directed by and external spiral. Flow shears off the edges of the spiral, atomizing the fluid. |

|

Misting NozzlesMisting nozzles produce a fine mist or fog. Due to the small size of the droplets, the drops may look as if they are floating. Instead, the drops are falling very slowly. The higher the pressure, the smaller the droplets. In cases of lower pressure, a larger number of smaller flow nozzles may be required. The following nozzles produce this spray pattern:

How is this spray pattern achieved through nozzle design? High pressure shears the liquid by forcing it through tiny openings. An impingement pin distributes the liquid as it leaves the nozzle, deflecting it on the chosen surface. Common misting nozzle geometries include pigtail/spiral, impingement, small diameter orifice with a whirl chamber, and air mixing/atomizing. Small Opening: Shear liquid by forcing it through tiny openings.

|

|

Straight Jet NozzlesA Straight Jet nozzle uses a straight orifice to produce a concentrated jet stream with a spray angle of 0°. The following direct pressure nozzles produce a Straight Jet spray pattern:

How is this spray pattern achieved through nozzle design? The Straight Jet is a single concentrated jet with a straight forward design. Many of the nozzles like the BJ & NF series listed above are categorized as Fan style nozzles. These nozzles have angled cuts which produce a flat pattern that fans out with a specific spray angle. The straight jet version does not use angled cuts, but instead uses a straight orifice that produces a jet stream with a spray angle of 0°. This design is common among Straight Jet nozzles. |

|

Tank Washing NozzlesTank washing nozzles can be used to clean, wash, and rinse every size container from small bottles and medium-sized drums to large railroad tankers. BETE has stationary tank cleaning nozzles, rotating tank cleaning nozzles, and tank cleaning machines. The following BETE nozzle series and types produce this spray pattern:

How is this spray pattern achieved through nozzle design? HydroWhirl S and HydroWhirl Poseidon: Water emitting from slots in the spray head causes the spray head to rotate, providing a quick, uniform rinsing action in an omnidirectional 360 degree spray. HydroWhirl Orbitor 100 and HydroWhirl Orbitor: Water flow through a rotor in the Orbitor body driving a series of gears that cause spray jets on the nozzle head to rotate in a controlled fashion with an omnidirectional 360 degree pattern. The jets provide high impact force for cleaning large tanks with hard to clean residues. TW: Water shears off the turns of the spiral design to create concentric rings of spray, resulting in available spray angles of 270 or 180 degrees. Coverage is not as uniform as other tank wash nozzle types, but the TW series can fit through smaller tank openings due to its smaller physical size. CLUMP or LEM: A manifold distributes water to several standard full cone nozzles with orientations positioned to achieve a full omnidirectional spray coverage. |