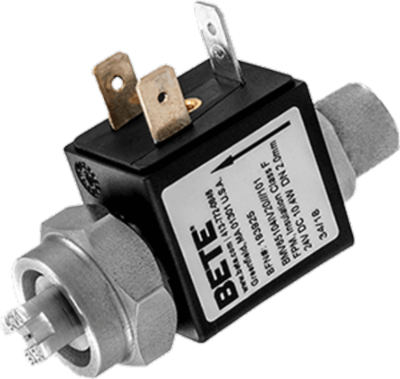

Industrial-Grade Electrically Actuated Intermittent Spray Nozzles

BETE HydroPulse® (EHPI) Spray Nozzles for Industrial Applications assure precision volumes of expensive ingredients and compounds are sprayed directly onto your processing target, with overspray waste virtually eliminated. Pair with the BETE FlexFlow™ Precision Spray Control System to achieve uniform coverage, even if you adjust your conveyor speed. The BETE Hygienic Electric HydroPulse (EHP) is the recommended solution for precision Food Processing applications.

BETE HydroPulse EHPI Design Features

- Interchangeable spray tips

- Efficient cycling on/off up to 50 cycles per second

- Does not require a compressed air source

- Precision volume sprays directly on the target

- Less waste and little overspray maintain a clean, safe environment

- Consistent and repeatable coverage improves product consistency

- Paired with the FlexFlow spray controller, high-frequency cycling known as Pulse Width Modulation (PWM) can vary the liquid spray flow rate at constant supply pressure with little change in spray performance by adjusting the duty cycle

Benefits of BETE HydroPulse EHPI

- Precision volume sprays directly on the target

- Reduced waste and minimal overspray maintain a clean, safe environment

- Uniform and repeatable coverage improves product consistency

- Each nozzle produces a wide range of flow rates

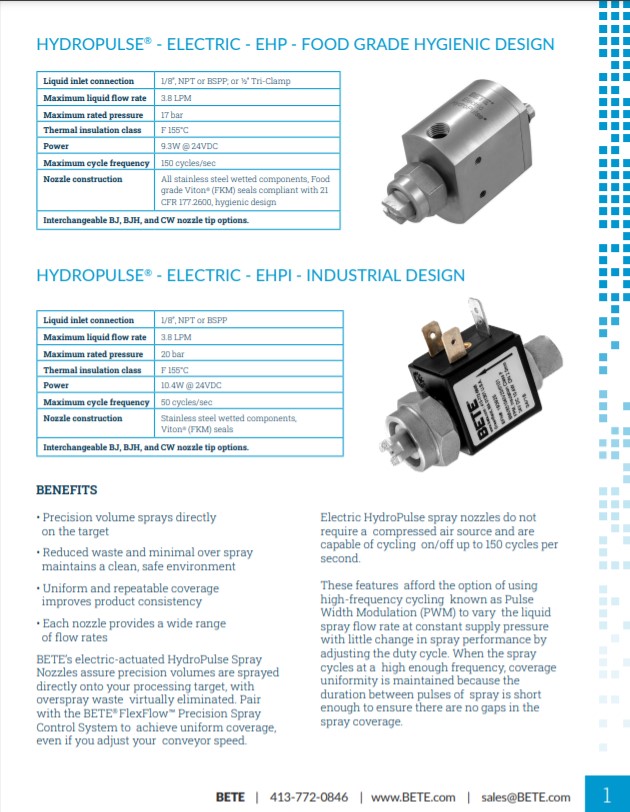

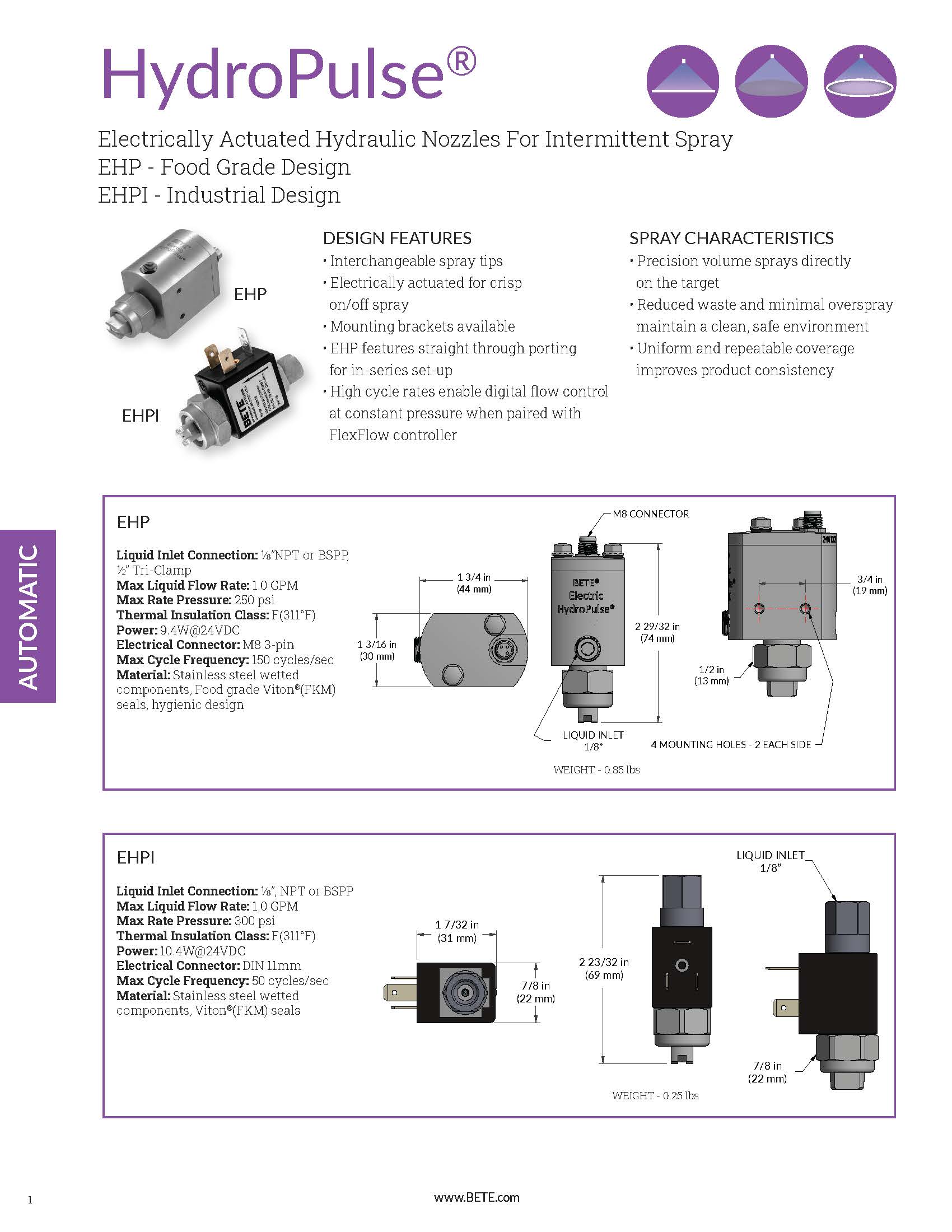

Product Specifications

|

Electric HydroPulse® spray nozzles do not require a compressed air source and are capable of cycling on/off up to 150 cycles per second. These features afford the option of using high-frequency cycling known as Pulse Width Modulation (PWM) to vary the liquid spray flow rate at constant supply pressure with little change in spray performance by adjusting the duty cycle. When the spray cycles at a high enough frequency, coverage uniformity is maintained because the duration between pulses of spray is short enough to ensure there are no gaps in the spray coverage. |

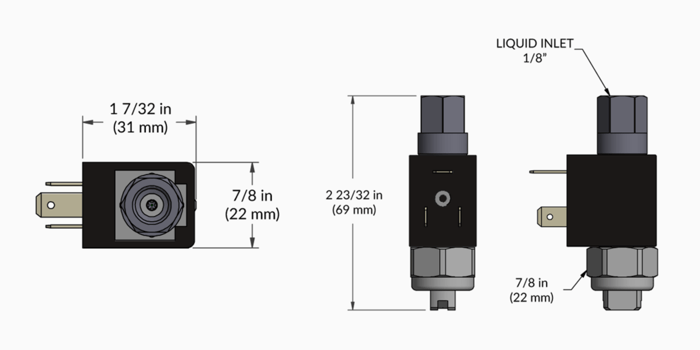

| Liquid Inlet Connection | 1/8″, NPT or BSPP |

|---|---|

| Maximum Liquid Flow Rate | 3.8 LPM / 1.0 GPM |

| Maximum Rated Pressure | 20 bar / 300 PSI |

| Thermal Insulation Class | F (155°C / 311°F) |

| Power | 10.4W @ 24VDC |

| Electrical Connector | DIN 11mm |

| Maximum Cycle Frequency | 50 cycles/sec |

| Nozzle Construction | Stainless steel wetted components | Viton® (FKM) seals |

| Interchangeable BJ, BJH, and CW nozzle tip options. | Due to pressure loss through the Electric HydroPulse body, the nozzle tip flow rate is different than the standard for each tip. Please reference the HydroPulse Electric Datasheet – Imperial | Metric PDF for a resolved flow rate range |