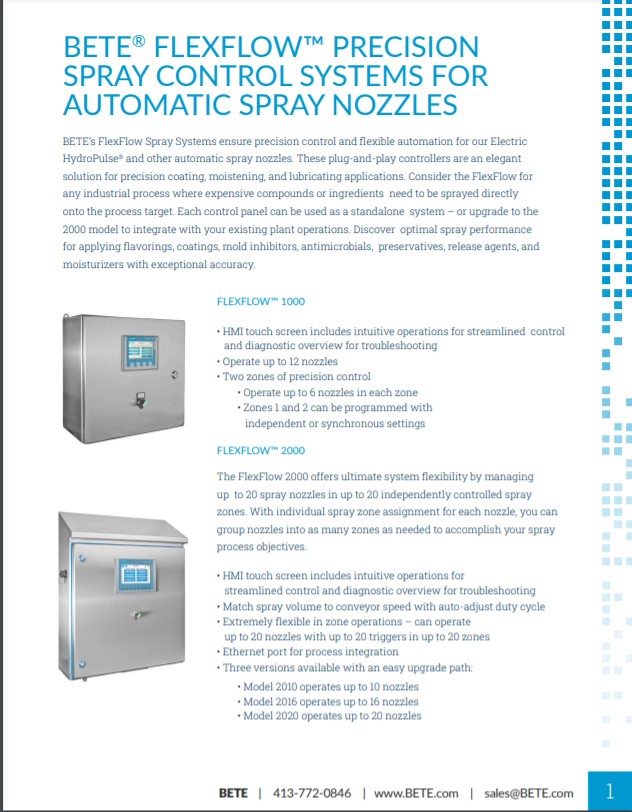

BETE FlexFlow Precision Spray Control Systems for Automatic Spray Nozzles

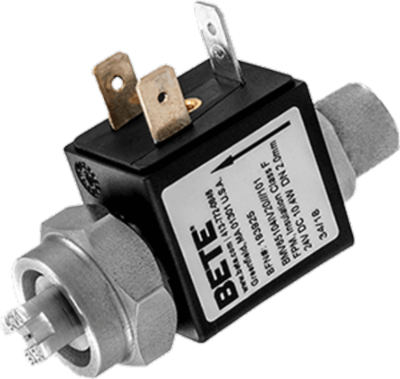

BETE FlexFlow Spray Systems ensure precision control and flexible automation for the BETE Hygienic Electric HydroPulse (EHP), the BETE Industrial Electric HydroPulse (EPHI) and other automatic spray nozzles. These plug-and-play controllers are an elegant solution for precision coating, moistening, and lubricating applications.

|

Consider the FlexFlow for any industrial process where expensive compounds or ingredients need to be sprayed directly onto the process target. Each control panel can be used as a standalone system – or upgrade to the 2000 model to integrate with your existing plant operations. Discover optimal spray performance for applying flavorings, coatings, mold inhibitors, antimicrobials, preservatives, release agents, and moisturizers with exceptional accuracy. |

|

FLEXFLOW 1000

Two zones of precision control:

All CE-compliant FlexFlow models sold will require a power cord supplied by the customer to ensure proper configuration without an adapter. BETE offers a 6' long standard 15A grounded plug for customers in North America as a standard add-on item. The FlexFlow spray controllers are supplied with a 24VDC power supply with a power input range from 85-264VAC, Single Phase.

|

|

FLEXFLOW 2000

The FlexFlow 2000 offers ultimate system flexibility by managing up to 20 spray nozzles in up to 20 independently controlled spray zones. With individual spray zone assignment for each nozzle, you can group nozzles into as many zones as needed to accomplish your spray process objectives.

All CE-compliant FlexFlow models sold will require a power cord supplied by the customer to ensure proper configuration without an adapter. BETE offers a 6' long standard 15A grounded plug for customers in North America as a standard add-on item. The FlexFlow spray controllers are supplied with a 24VDC power supply with a power input range from 85-264VAC, Single Phase.

|

Features and Upgrades

BETE FlexFlow precision spray controllers are standalone electrical control panels intended to provide user-friendly control of BETE Electric HydroPulse (EHP/EHPI) series electric-actuated spray nozzles.

|

A Siemens brand Programmable Logic Controller (PLC) and associated hardware operates the nozzles. Spray zones can be triggered manually or they can be triggered automatically using digital inputs from process sensors. User-adjustable signal delays provide the most accurate spray timing functionality. |

|

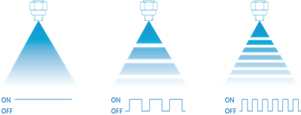

The spray flow rate can also be electronically controlled by pulsing the sprays while adjusting the ratio of ON versus OFF dwell time within each cycle. Pulsing at high frequency allows the average flow rate to be adjusted while maintaining constant fluid supply pressure and the appearance of continuous, uniform coverage. This flow control process is known as Pulse Width Modulation (PWM).

The BETE FlexFlow™ spray controllers are standalone electrical control panels that provide user-friendly control of BETE Electric HydroPulse (EHP) series electric-actuated spray nozzles. Hygienic enclosure wall-mounts are an available upgrade add-on. A Siemens brand Programmable Logic Controller (PLC) and associated hardware operate the nozzles. Spray zones can be triggered manually, or they can be triggered automatically using digital inputs from process sensors. User-adjustable signal delays provide the most accurate spray timing functionality. |

|

A touchscreen Human Machine Interface (HMI) allows users to configure the spray system and adjust spray parameters through an easy-to-navigate menu of options. Adjustable parameters for each spray zone include nozzle cycle rate, duty cycle, trigger signal delays, and trigger state. |

|

A cable gland plate comes standard with every FlexFlow control panel. Only pierce as many openings as needed through the membrane for easy access to field wiring. |

|

The FlexFlow 2000 includes an Ethernet port for process integration with your existing plant operations. |

|

A hygienic enclosure upgrade is available for any FlexFlow System. |

|

Hygienic enclosure wall-mounts are an available upgrade add-on. |