Bete XA Spray Nozzles

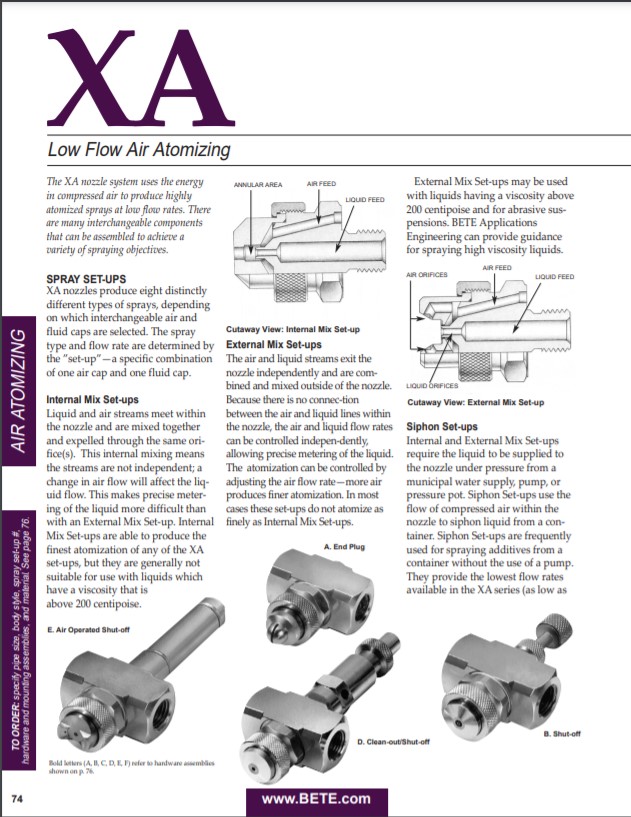

The Bete XA nozzle system uses the energy in compressed air to produce highly atomized sprays at low flow rates. There are many interchangeable components that can be assembled to achieve a variety of spraying objectives.

Types of Spray Set-Ups

Bete XA nozzles produce eight distinctly different types of sprays, depending on which interchangeable air and fluid caps are selected. The spray type and flow rate are determined by the ”set-up”—a specific combination of one air cap and one fluid cap.

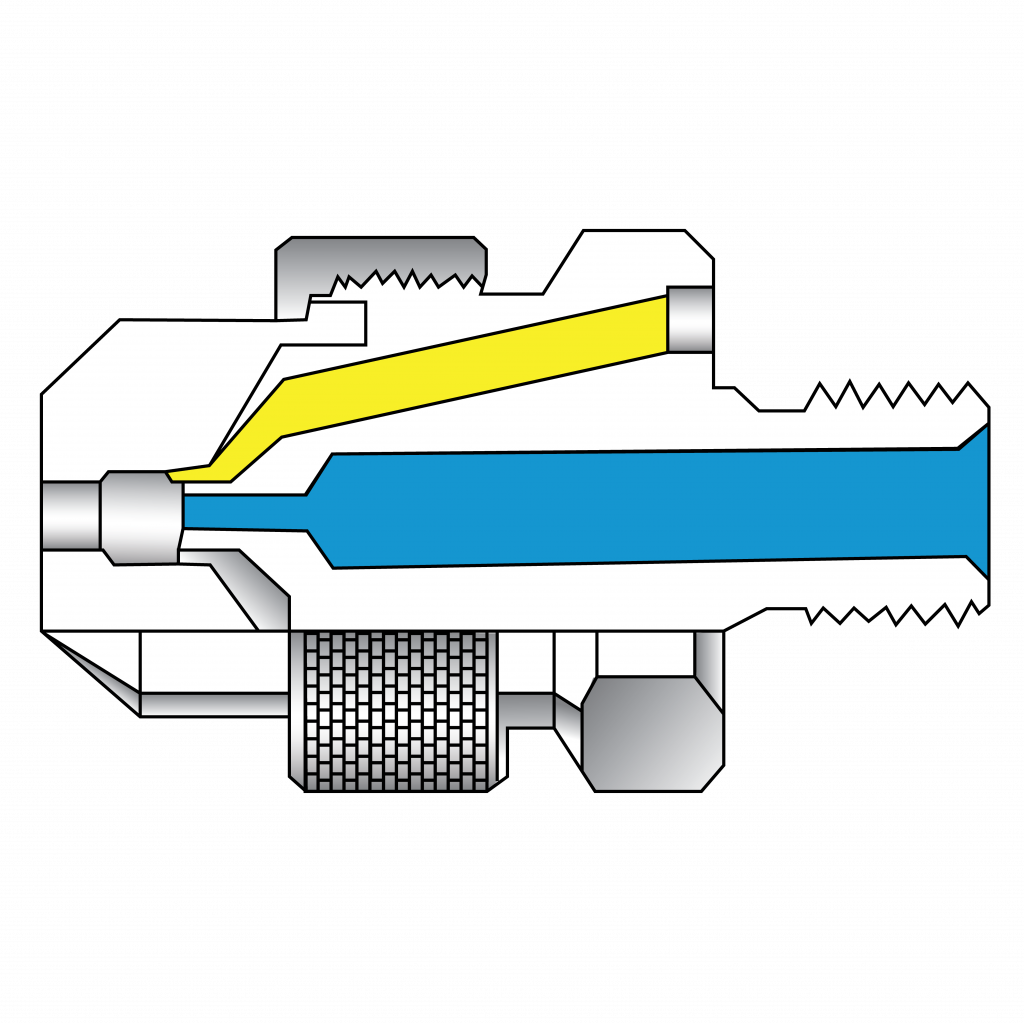

Internal Mixing

- Liquid and air streams come together inside the nozzle and are mixed, and they exit through the same orifice.

- The streams are not independent; airflow changes will affect the liquid flow.

- Not suitable for viscous liquids above 200 cP.

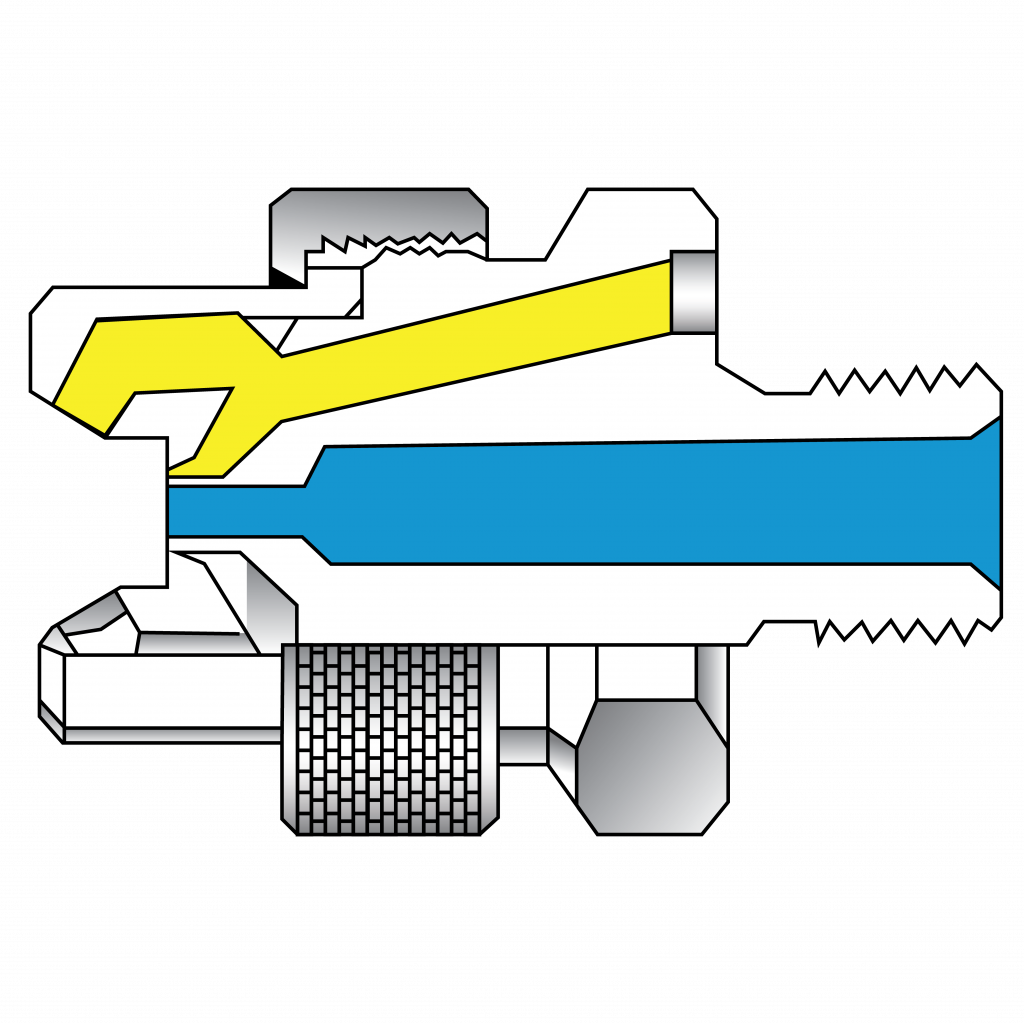

External Mixing

- The air and liquid streams exit the nozzle independently through each orifice.

- Air and liquid flow rates can be independently controlled, allowing precise fluid metering.

- Suitable for all liquids, including viscous liquids above 200 cP.

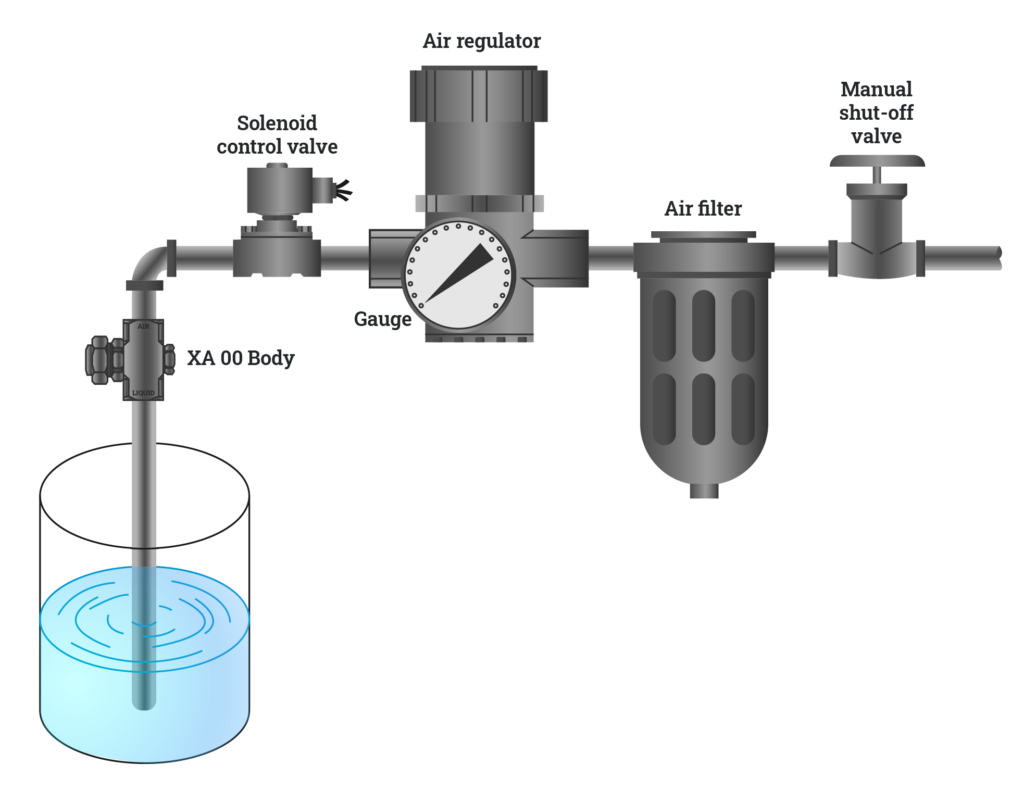

Siphon Set-Ups

Internal and External Mix Set-ups require the liquid supplied to the nozzle under pressure from a municipal water supply, pump, or pressure vessel. Siphon Set-ups use the flow of compressed air within the nozzle to siphon liquid from a container. Siphon set-ups are frequently used for spraying additives from a container without a pump. They provide the lowest flow rates available in the XA series (as low as 0.1 GPH).

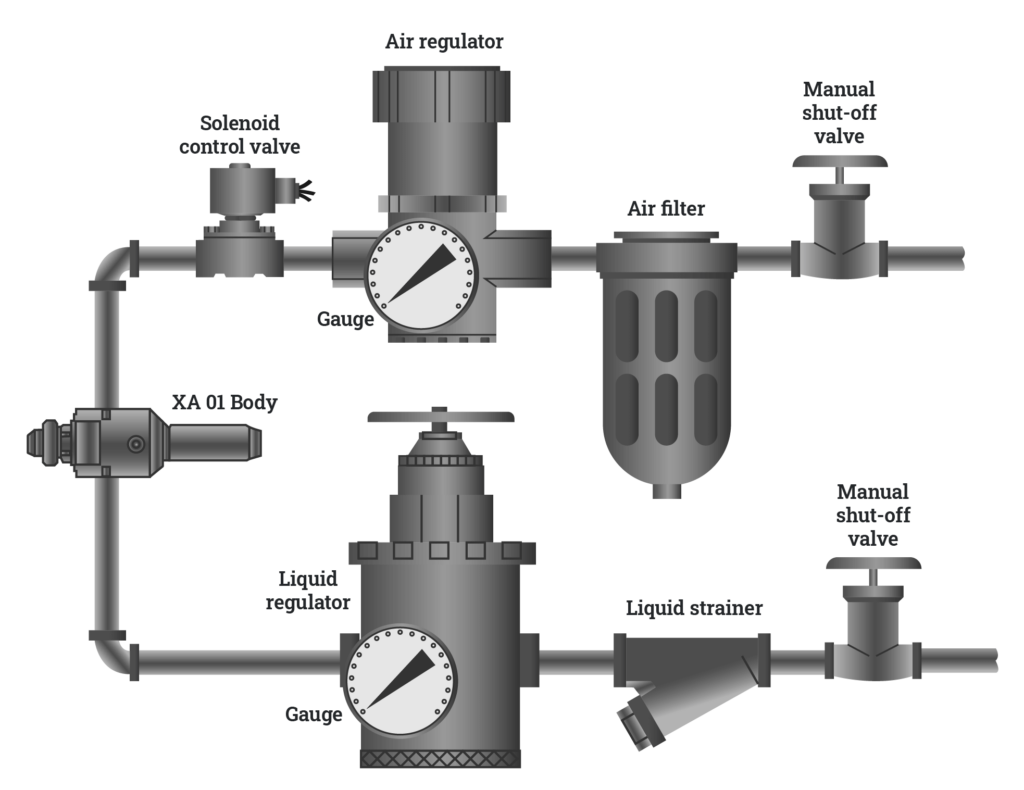

Pressure System Set-Ups

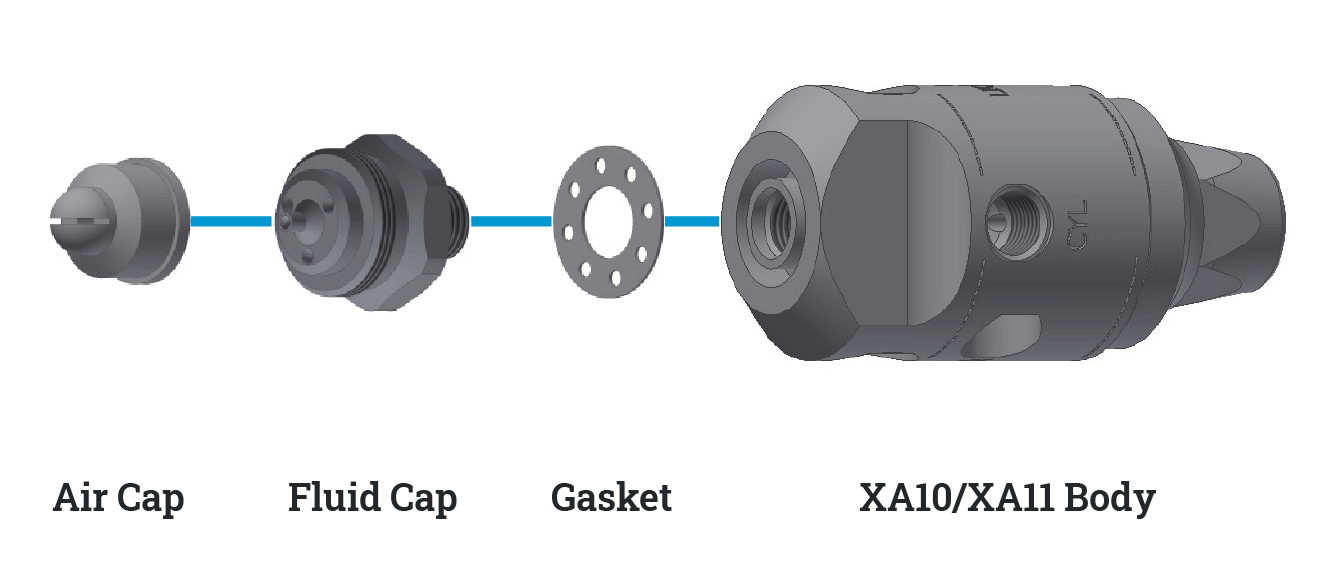

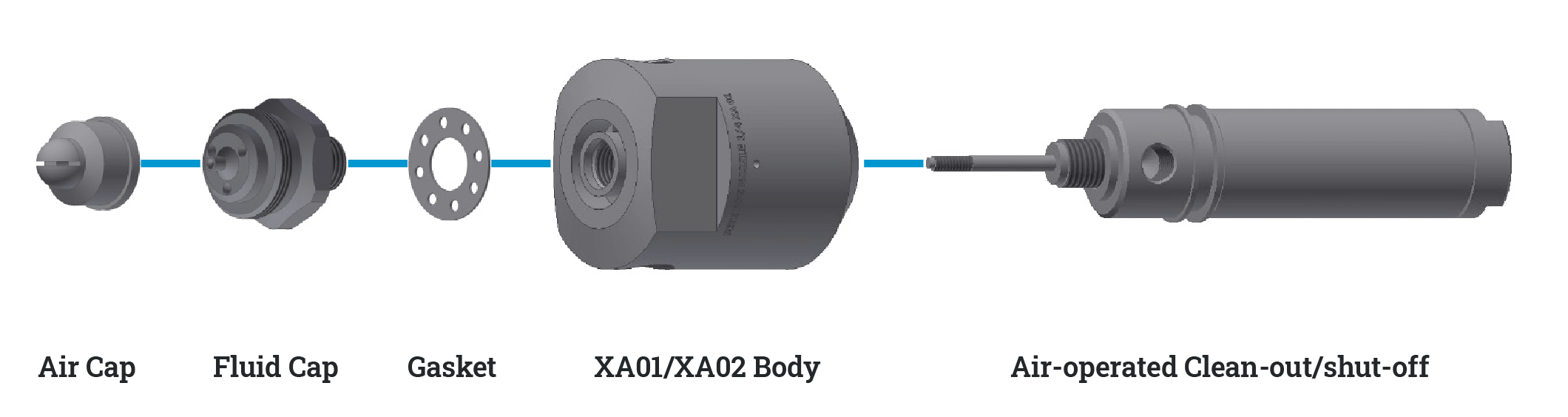

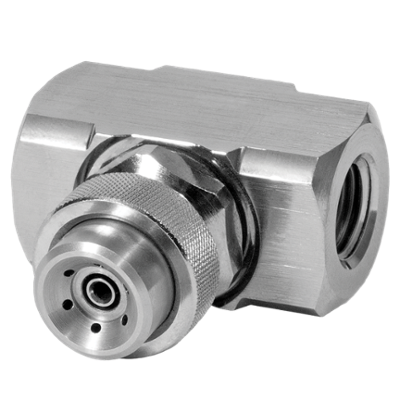

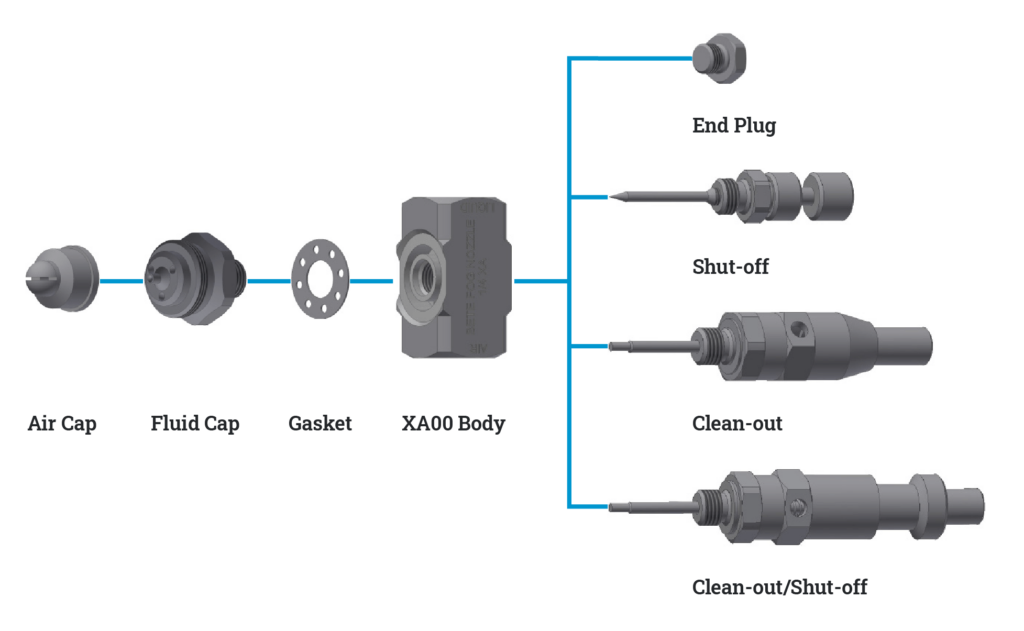

Basic XA Operation & Components

The basic XA spray nozzle assembly consists of a body, a spray set-up, and a hardware assembly that can provide shut-off and clean-out capabilities.

Non-Automatic

The basic XA body requires hardware assembly for manual shut-off or clean-out/shut-off.

Recommended Body Styles: XA00, XA03, XA05

Recommended Hardware Assemblies: End Plug, Shut-off, Clean-Out, or Clean-out/Shut-off

Automatic

The round XA body can be equipped with an air cylinder to provide shut-off or clean-out/shut-off for automatic operation.

Recommended Body Styles: XA00, XA01, XA02, XA10, XA11

Recommended Hardware Assemblies: Air-operated Shut-off, or Air-operated Clean-Out/Shut-off