BETE PTFE Corrosion-Resistant Slow Rotating Tank Cleaning Devices

Tank Washing Spray Nozzles are ideal for high-impact cleaning.

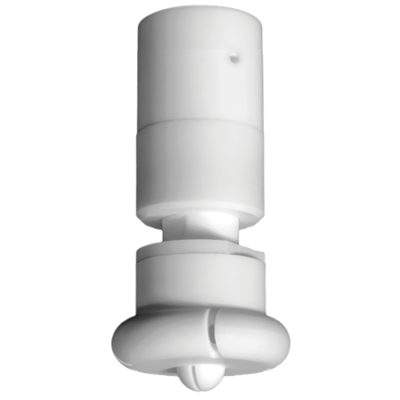

The HydroWhirl Poseidon is a versatile Clean-In-Place (CIP) rotating tank-washing nozzle that combines slow-moving rotation and a high-impact spray pattern for more efficient tank cleaning. It is ideal for tanks up to 22 ft. in diameter, often found in the food, beverage, chemical and pharmaceutical industries where superior cleaning with reduced cycle times and low water, energy and chemical consumption are important considerations.

The bearingless design provides a slow, nearly constant rotation speed over the operating pressure range. The slow, roughly constant rotation speed of the HWP results in more efficient cleaning and use of resources over static spray balls and other rotating spray ball designs. Through increased impact and more extended spray dwell time on the target surface.

BETE HydroWhirl Poseidon Spray Nozzles Benefits

- Cleans more quickly and uses less water and lower pressure than static tank washers

- Complete 360° omnidirectional coverage

- Slow rotation speed provides higher impact and more efficient cleaning.

- Durable PTFE nozzle construction withstands extreme chemical and elevated temperature environments.

- Simple internal design allows reliable flow-through operation

- Design validated by lab testing to 200°F (93°C)

- Maintenance-friendly design allows disassembly, inspection, and reassembly with basic hand tools.

- Made from FDA-approved materials for use in Clean-in-Place (CIP) applications

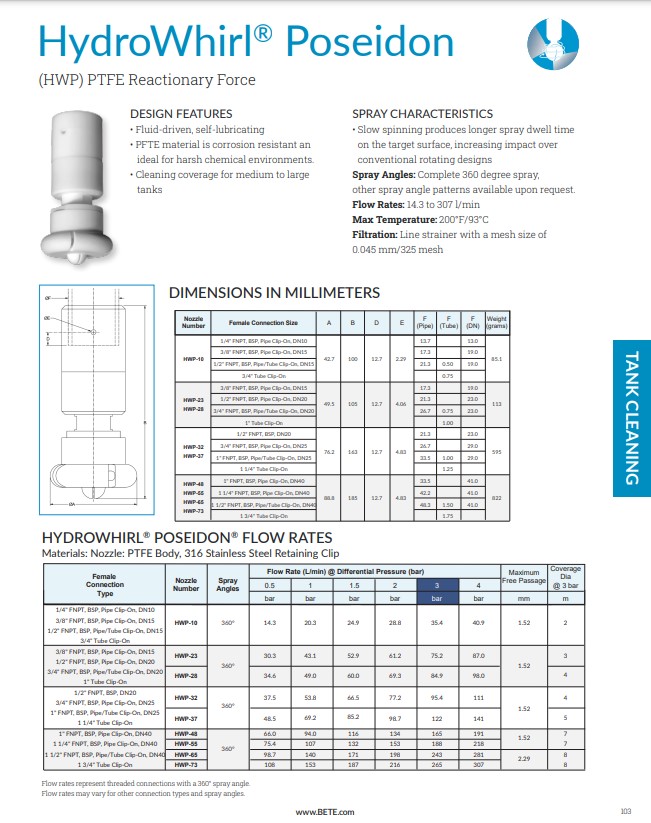

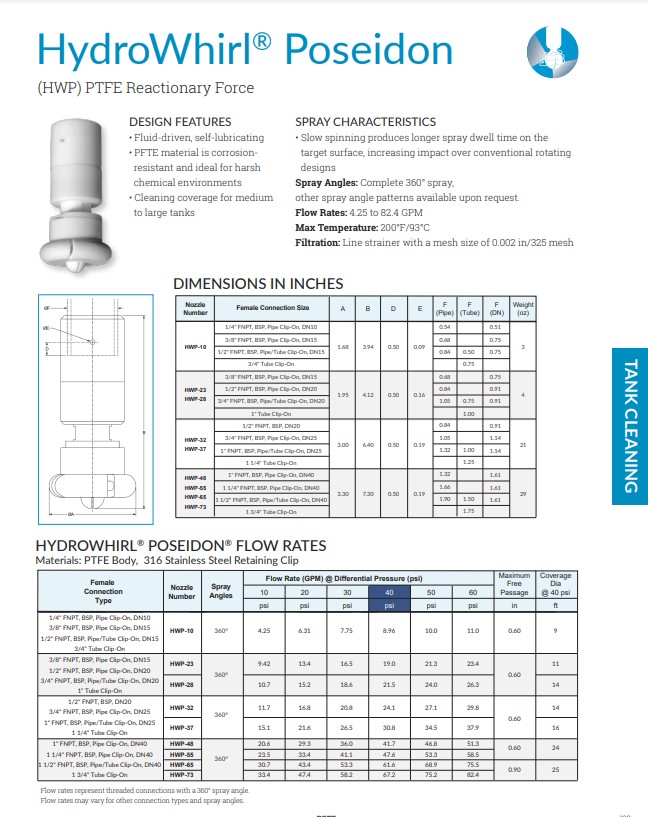

Design Features of HydroWhirl Poseidon Tank Cleaning Nozzles

- Cleans more quickly, and uses less water and lower pressure than static tank washers

- PTFE construction:

- Ideal for harsh chemical environments

- Corrosion resistant

- Chemical Processing Tanks

- IBC Tote Cleaning

- Three connections: pipe, tube, or DIN clip-on. Threaded connections available upon request.

- Made from FDA-approved materials for use in Clean-In-Place (CIP) applications.

- Slow spinning, longer spray dwell time on the target surface increases impact over conventional rotating designs

- Complete 360° omnidirectional spray pattern

BETE HydroWhirl Poseidon Spray Characteristics

- Slow spinning, longer spray dwell time on the target surface increases impact over conventional rotating designs

- Complete 360° omnidirectional spray pattern

- Minimum Tank Opening: Small: 3″ (75mm), Large: 3.3″ (83mm)

| Available Spray Angles | Flow Rate Range |

| 180 - 360° | 4.45 to 95.3 gpm |

| Available Connection Types | Material |

|

PTFE |

How Spray Pattern is Achieved for BETE HydroWhirl Poseidon Spray Nozzles

- The bearing-free design provides a slow, nearly constant rotation speed over the operating pressure range. The slow and constant speed of the HW results in more efficient cleaning and use of resources over static spray balls and other rotational designs through increased impact and longer spray dwell time on the target surface.

- Atomization is achieved by the water being spun inside the nozzle and exiting an orifice.

-Tank-Cleaning-Nozzles/BETE-HydroWhirl-S-HWS2-tank-cleaning-nozzle.png)