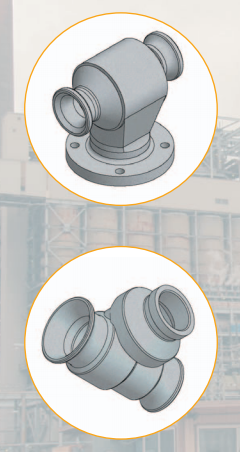

Tangential Double Hollow Cone Spray Nozzles

Bete DTH spray nozzles, available in silicon carbide, feature a double hollow cone tangential design.The FGD (Flue Gas Desulfurization) process requires nozzles that are guaranteed to function over prolonged periods of time in the harsh conditions brought upon by factors such as pH and chloride concentrations.

The BETE bi-directional DTH series feature two orifices, each of which forms a hollow cone pattern, with one spraying downward and the other spraying upward. The geometry of the design has been developed to produce the most uniform possible spray distribution in each cone.

The upward spraying cone accomplishes two objectives:

- reduces the pressure drop across the absorber

- increases the average droplet residence time.

The DTH is also available with unequal flows in the cones such as 70% upward spraying and 30% downward spraying

Gas Scrubbing Nozzles | Cleaning Nozzles

Scrubber nozzles are used to remove pollutants and other chemical contaminants from process gases, liquids, and equipment. Scrubbers can remove sulfur oxides (SOx) from boiler exhaust in coal fired power plants, nitrous oxides (NOx) from combustion streams, acids from chemical processing off gases, disinfectants from drinking water, particulates from process gas, and odors from water water treatment plants among many other potential uses.

While there are many specific types and uses for scrubbers, they typically fall under to general categories of basic scrubber designs:

- Open Scrubbers: These nozzles are designed to spray the scrubbing liquid directly into the process stream. Open scrubbers depend on the correct droplet size and process conditions in order to maximize the reaction rate or mass transfer rate as these are usually dependent on surface area to volume ratio of the droplets.

- Packed Scrubbers: These nozzles work by spraying a scrubbing fluid over a packing material within a tower, which has an upward or horizontally flowing gas stream passing through the packing. The packing becomes saturated with the liquid and creates a film for the gas/liquid interaction to occur.

BETE has decades of experience providing scrubber nozzle solutions for a variety of processes and companies worldwide. To learn more about which nozzle would be right for your application, please explore the specific categories listed below, or contact our experienced engineers.

Design Features:

- The BETE bi-directional DTH series features two orifices, each forming a hollow cone pattern, with one spraying downward and the other spraying upward

- The upward spraying cone reduces the pressure drop across the absorber and increases the average droplet residence time

- The DTH is also available with unequal flows in the cones, such as 70% upward spraying and 30% downward spraying

Scrubbing Applications:

- Aeration / Air Stripping

- Dry Scrubbing

- Flue Gas Desulphurization (FGD)

- Marine Gas Scrubbing

- Odor Control

- Packed Scrubbers

- SCR/SNCR

- Venturi Scrubbing

- Wash Water Injection

BETE DTH for Flue Gas Desulphurization:

Double Cone, wide angle, high flow:

How Spray Pattern is Achieved

- The DTH is designed with two orifices, forming a hollow cone spray pattern

- The geometry of the design has been developed to produce the most uniform spray distribution possible in each cone