Easy Maintenance and Wear Resistant Spray Dry Technology

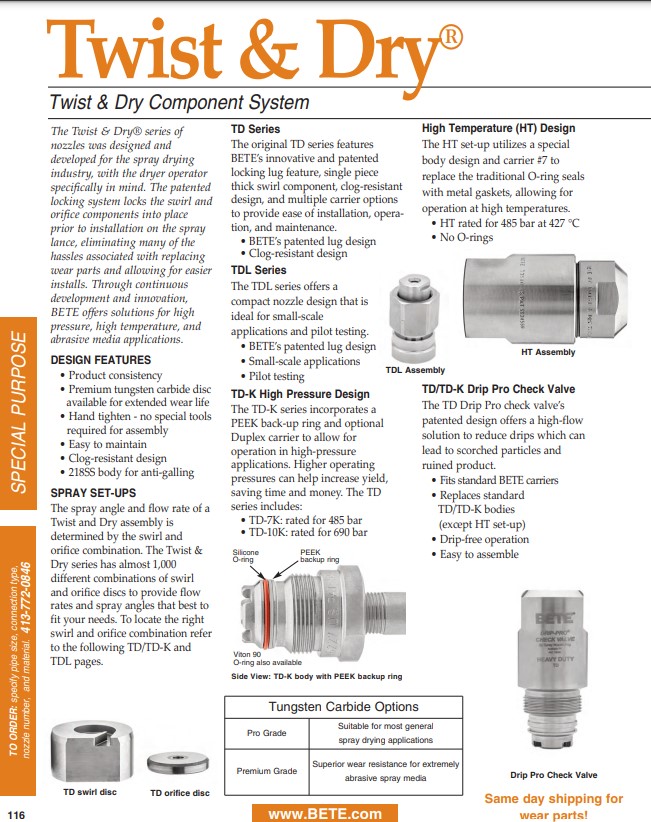

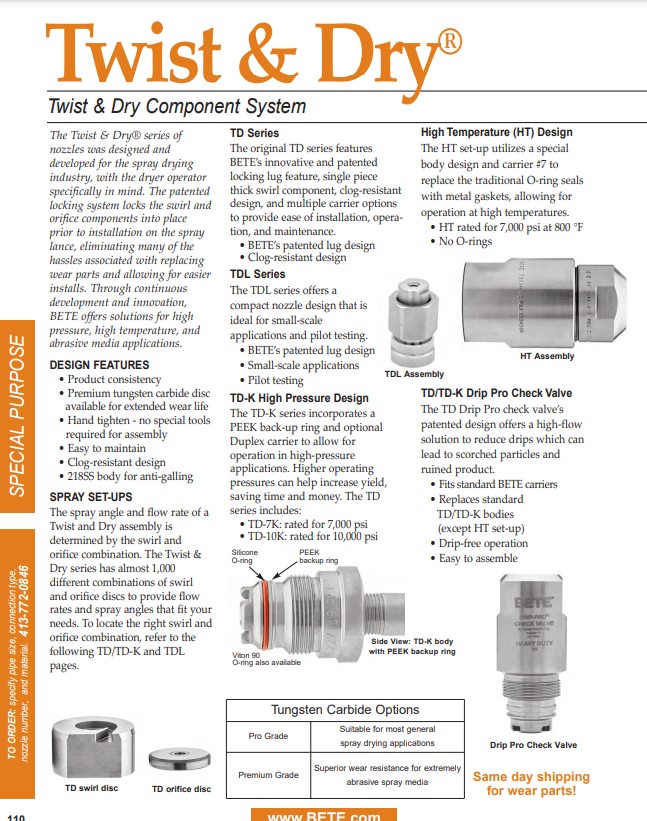

The range of operating pressure range for pressure nozzles used in spray drying is from about 250 PSI (17.4 bar) to about 10,000 PSI (690 bar). The BETE Twist & Dry is capable of handling this entire pressure range. The TD-K should be used for pressures above 3500 PSI and up to 10,000 PSI. Includes models TD-7K (up to 7,000 psi) and TD-10K (up to 10,000 psi)

BETE TD-K Twist & Dry Nozzles Design Features

- Patented locking mechanism for quick and easy change-out

- Fewer parts; rugged design: one-piece swirl unit greatly reduces breakage of tungsten carbide pieces

- BETE provides complimentary software support provided to customers to simplify swirl unit and orifice disk selection.

- Replacement swirls and discs are readily available

Advancements from current line

- New high pressure capacity; increased from 3,500 psi to 10,000 psi

Operating Conditions for BETE TD-K (High Pressure Twist & Dry) Spray Nozzles

- TD-10K: up to 10,000 psi at temperatures up to 450°F; achieved with a PEEK backup ring and Duplex 2205 carrier

- TD-7K: up to 7,000 psi at temperatures up to 450°F; achieved with a PEEK backup ring

Customer Requirements for BETE TD-K (High Pressure Twist & Dry) Spray Nozzles

- Spray Dryer Operators have reported that they can increase yield by operating at higher pressures.

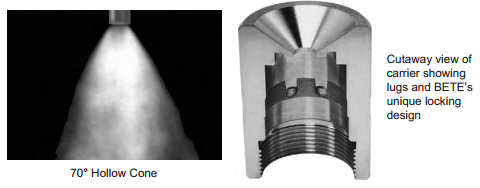

How Spray Pattern is Achieved

- Spray exits on the same axis it enters

- Internal channels or vanes causes the liquid to spin, and the centrifugal force exerted upon the geometry of the exit creates the spray pattern

- Spray is concentrated on outer edges

- Smaller droplets than full cone

| Available Spray Angles | Flow Rate Range |

| 50 - 85° | 0.149 to 36.8 gpm |

| Available Connection Types | Materials |

|

Tungsten Carbide (Pro) / 303 / 218, Tungsten Carbide (Premium) / 303 / 218, Tungsten Carbide (Pro) / Duplex 2205 / 218, Tungsten Carbide (Premium) / Duplex 2205 / 218 |

BETE’s solution: By modifying the TD body to take a backup ring, BETE developed the TD-K configuration which allows leak-proof operation up to 10,000 psi.

BETE TD-K Twist & Dry Nozzle Benefits

- Operate at high pressures and temperatures

- Greater yield capacity

- Safe, leak-proof operation

- Minimal additional cost