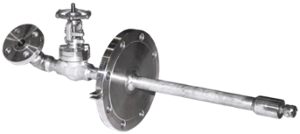

Discover the BETE Original Pigtail Spray Nozzle: Ideal for Quenching, Scrubbing, and Evaporative Cooling

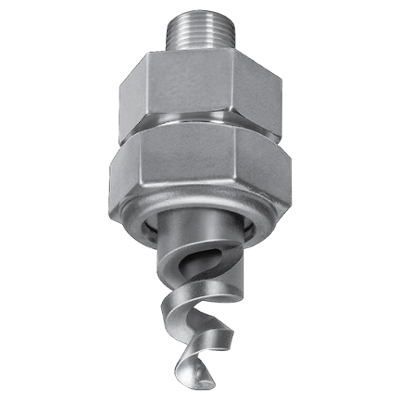

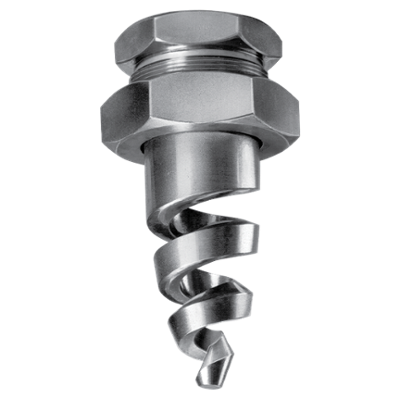

BETE's innovative TF original spiral nozzle design stands as a significant breakthrough in nozzle technology. This design atomizes liquids into small droplets through a continuously descending spiral, ensuring unrestricted flow through relatively large passages. The outcome is a higher discharge velocity, allowing for reduced pumping pressures while achieving the necessary atomization.

Explore the Benefits of BETE TF Full Cone and Hollow Cone Spiral Nozzles

- Originator of the spiral nozzle concept by BETE

- Often referred to as pigtail nozzles, corkscrew nozzles, or helix nozzles

- Exceptional energy efficiency

- One-piece construction with no internal components

- Reliable performance resistant to clogging

- High discharge velocity

- Standard male connection; special order option for female connection

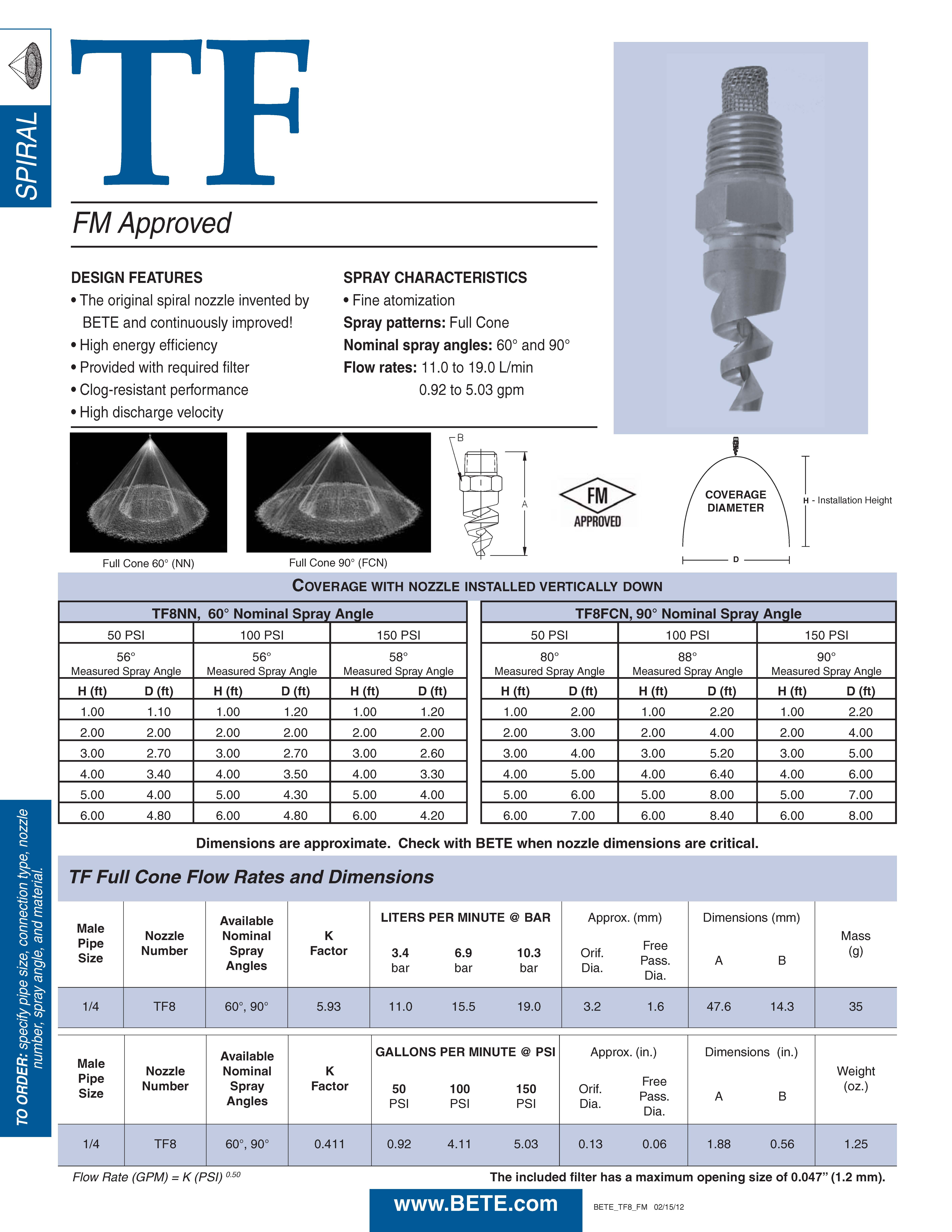

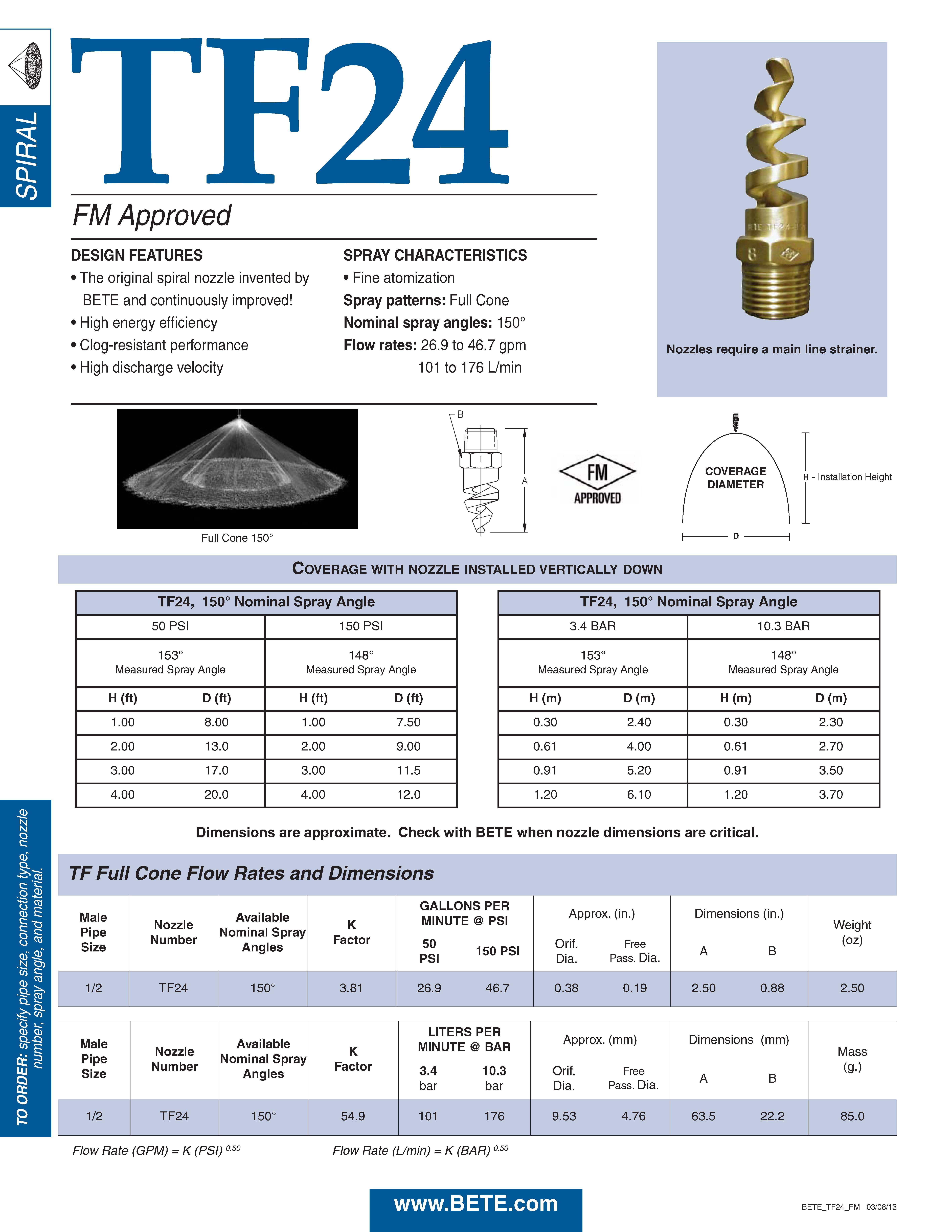

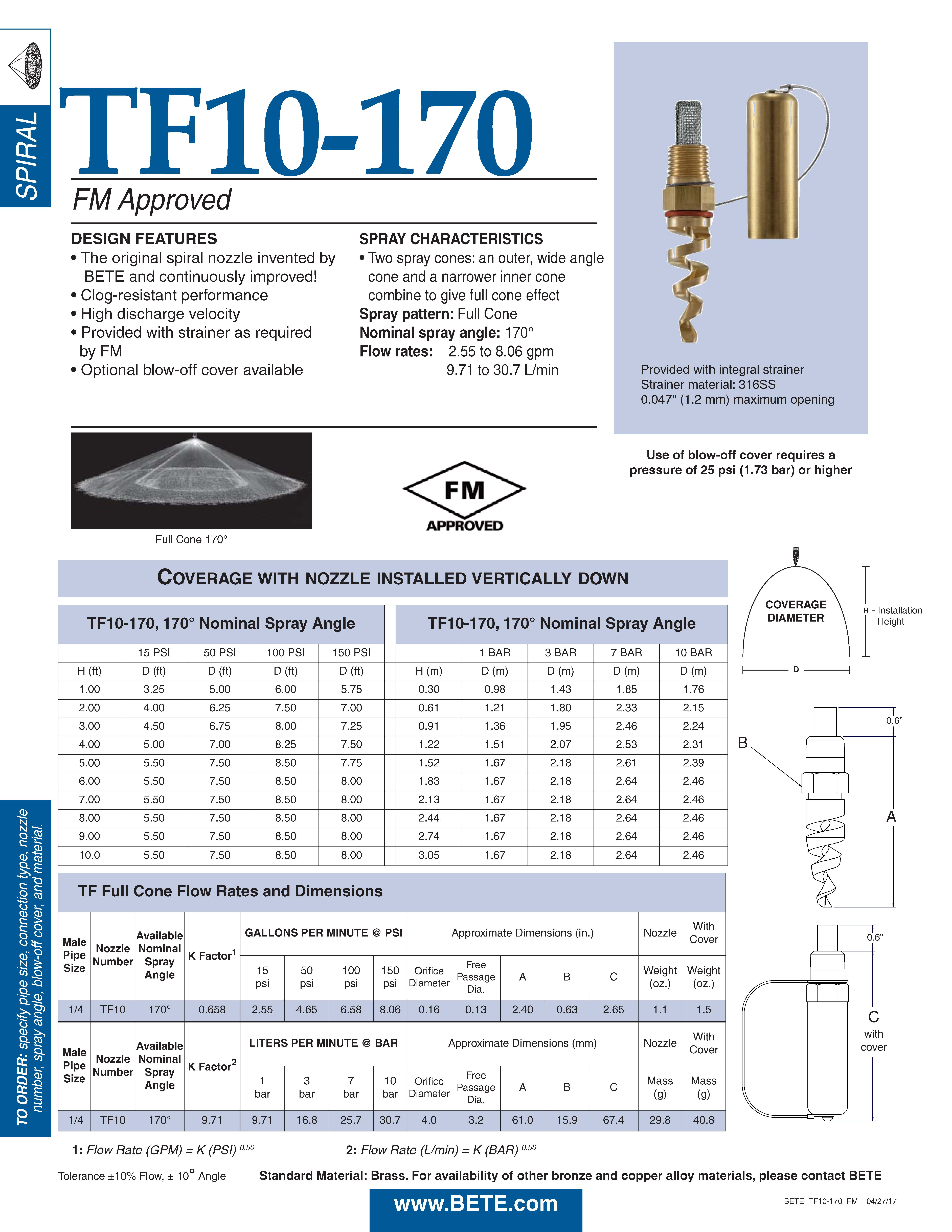

- FM approval for TF24-150, TF8NN, and TF8FCN (brass models)

- Widely used in applications such as quenching, scrubbing, and evaporative cooling

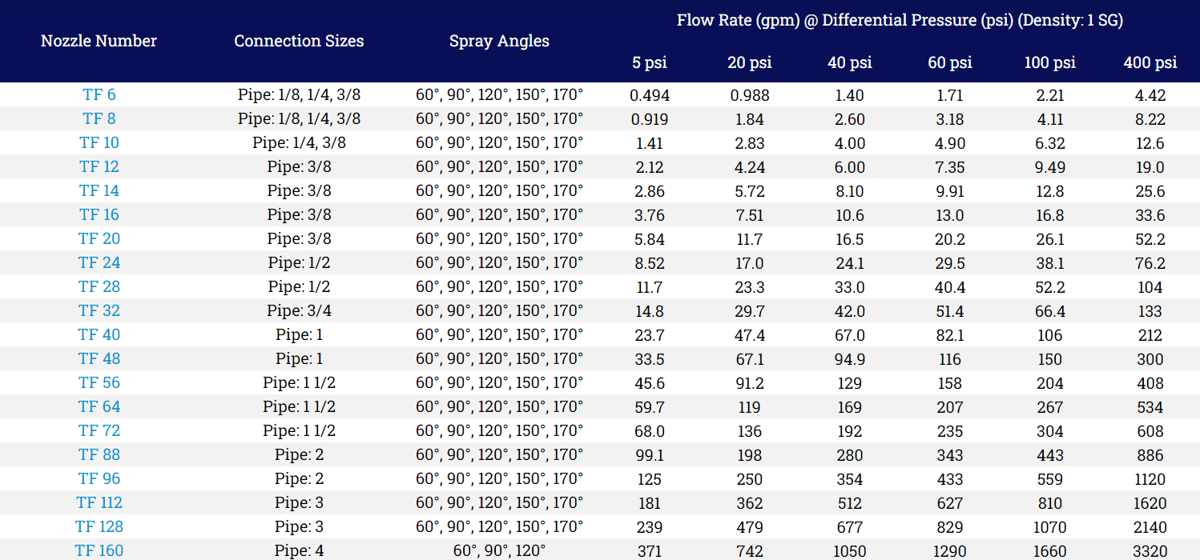

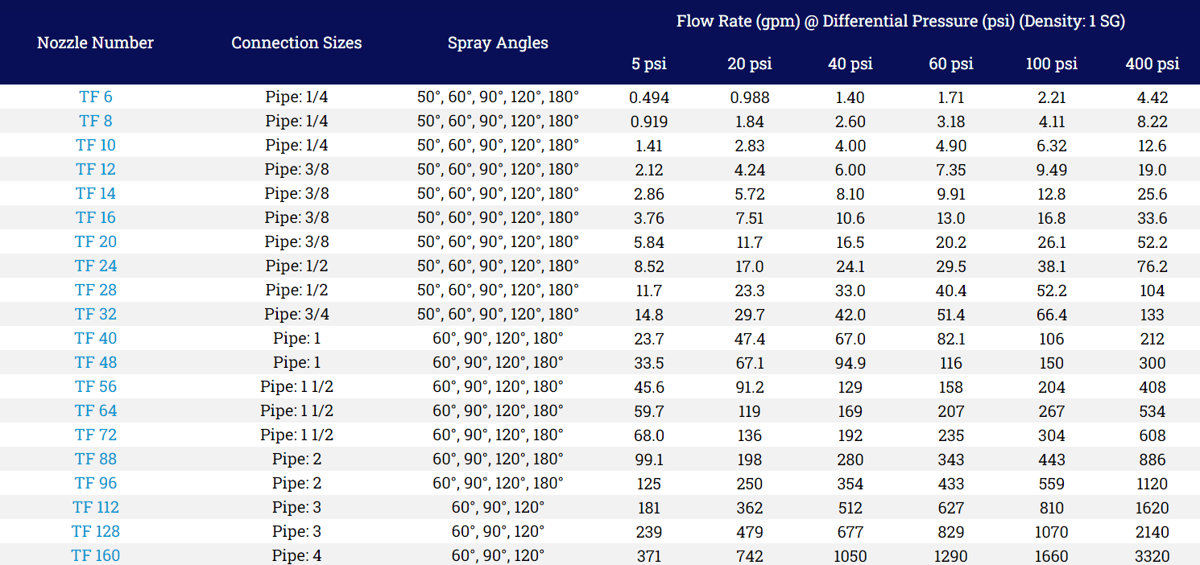

Key Spray Characteristics of BETE TF Spray Nozzles

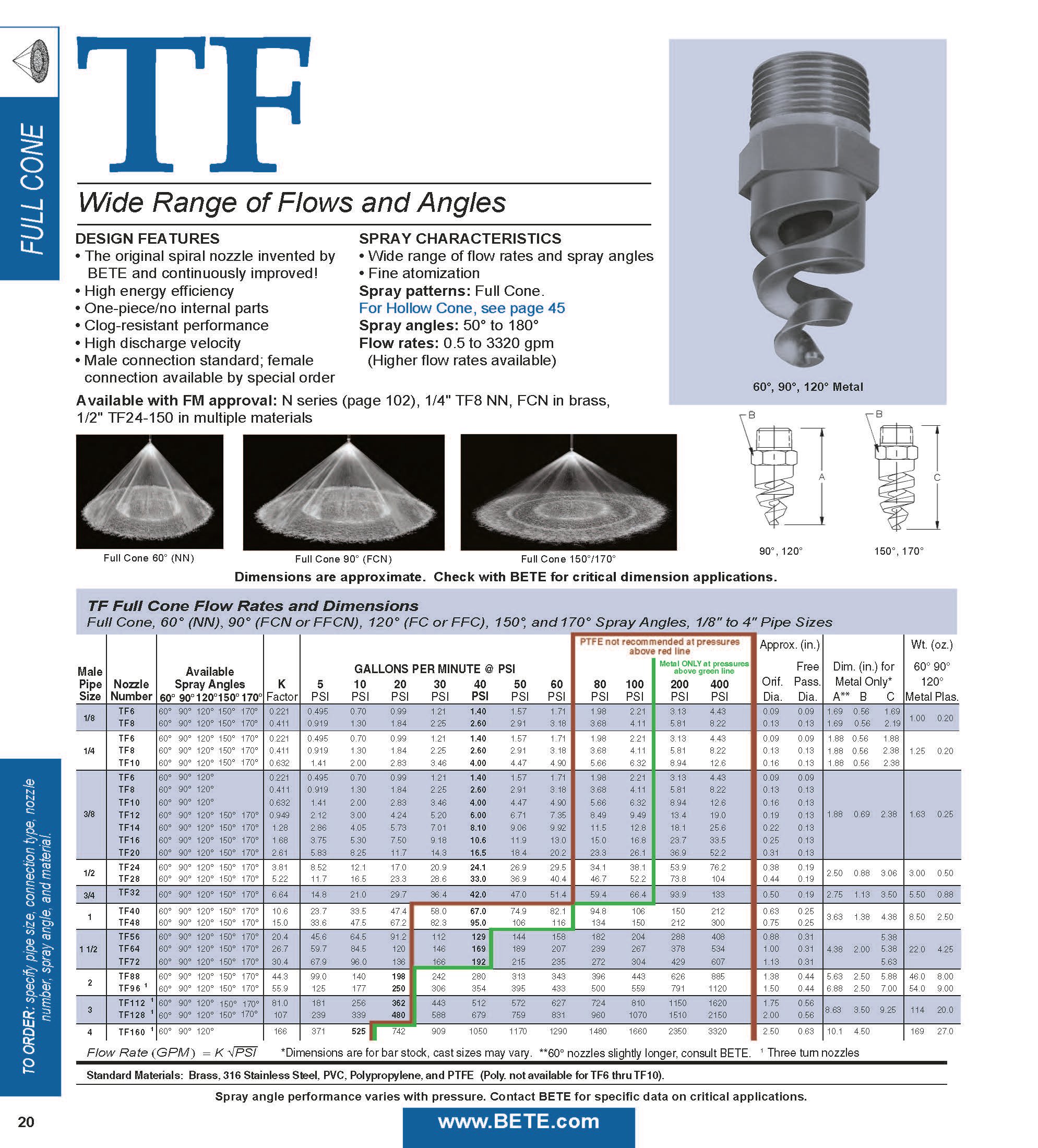

- Wide range of flow rates and spray angles

- Fine atomization

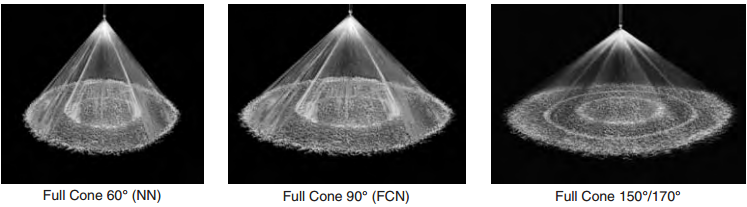

- Spray Patterns

- Full Cone

- Hollow Cone

Understanding How BETE TF Nozzles Achieve Their Spray Pattern

- The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form two to three bands of relatively coarse droplets surrounded by wider bands of relatively fine droplets

- Produces the finest droplet size of any direct pressure nozzle for very fine atomization

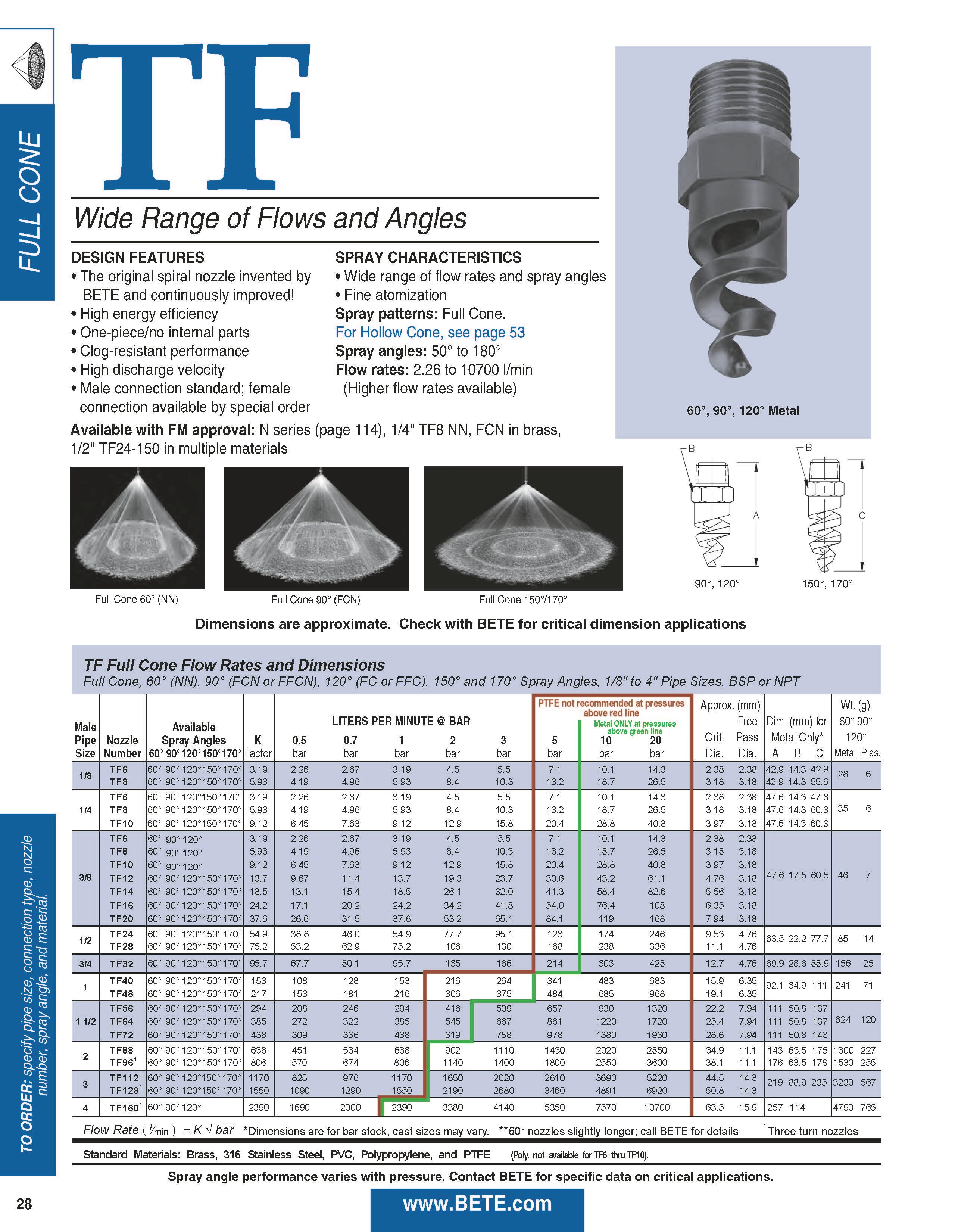

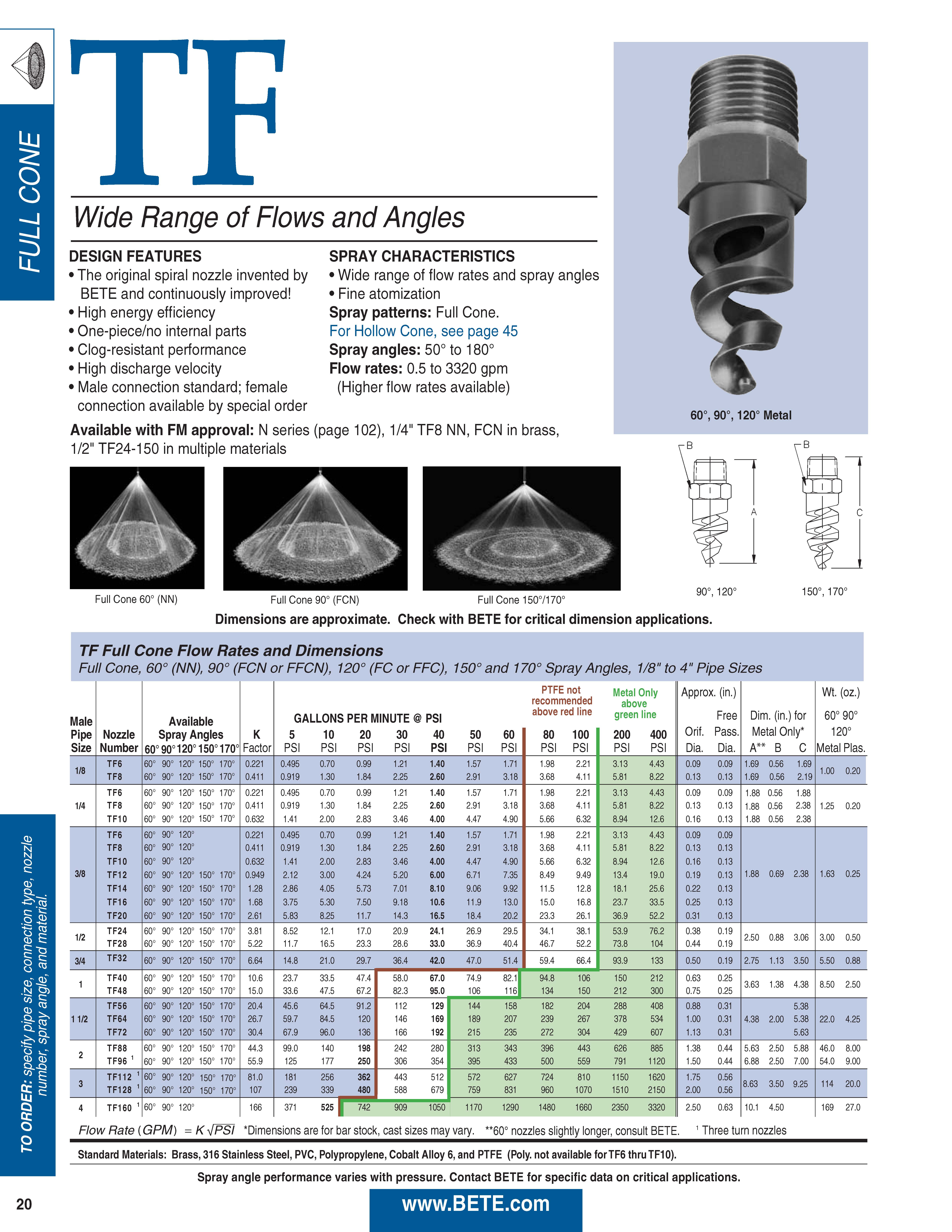

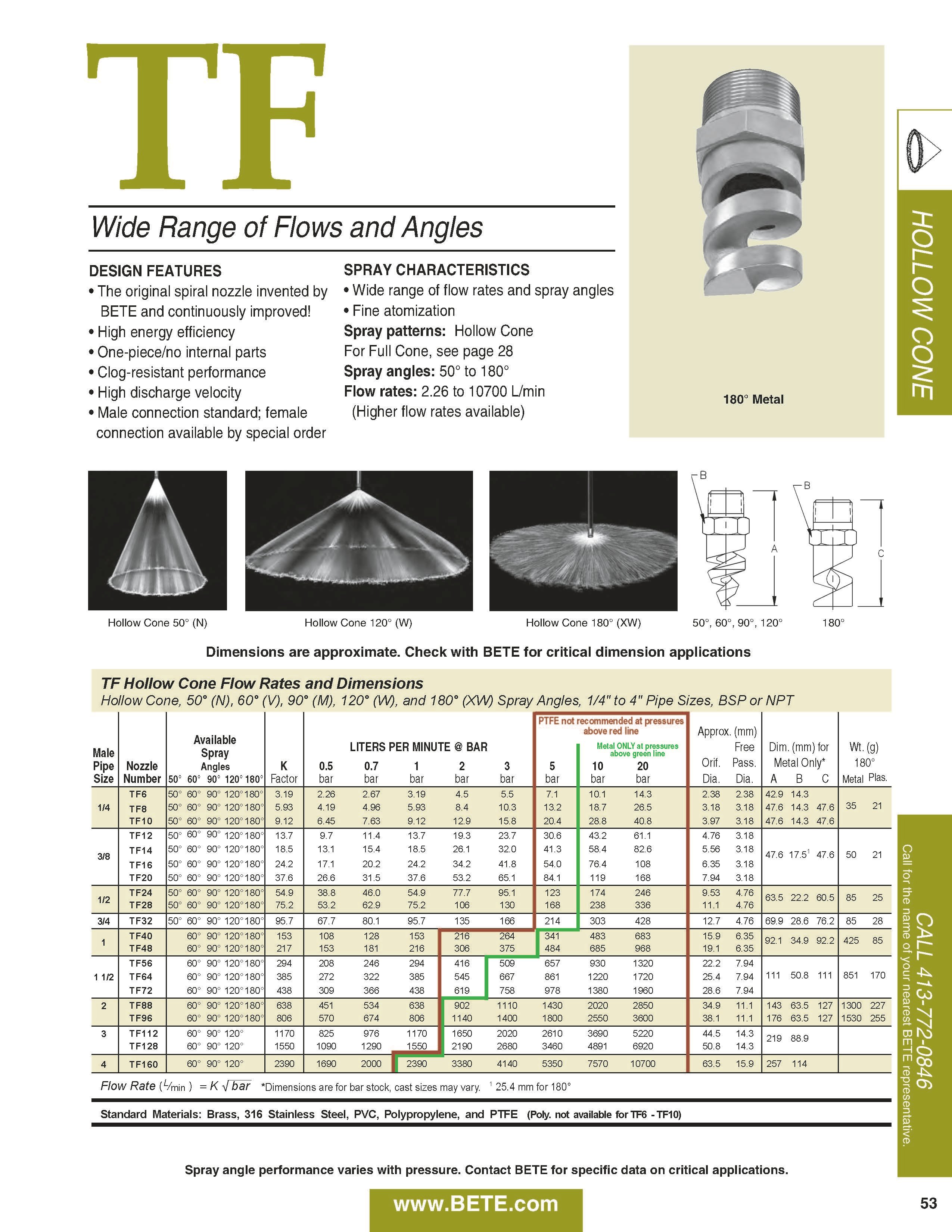

| Available Spray Angles | Flow Rate Range |

| 50 - 180° | 0.494 to 3710 gpm |

| Available Connection Types | Materials |

|

Brass, 316, 310, 347, Cobalt Alloy 6, Duplex 2205, A494 CW6MC (cast Nickel Alloy 625), A494 CW2M (cast Nickel Alloy C-276), A494 CX2MW (cast Nickel Alloy C-22), A494 CU5MCuC (cast Nickel Alloy 825), PVC, CPVC, PVDF, PTFE, Nickel Aluminum Bronze, Polypropylene |

BETE TF Full Cone

BETE TF Hollow Cone

BETE TF Nozzles Spray Angle

BETE TF Spray Nozzle Applications

- Absorption

- Aeration

- Cooling: Deluge

- Cooling: Evaporative

- Cooling: Parts

- Cooling: Pond

- Corrosion Resistant Nozzles

- Disposal: Evaporative

- Dust Control: Air-handling Ducts

- Dust Control: Area

- Fire Protection: Deluge

- Fire Protection: Marine

- Fire Protection: Special

- Fire Protection: Toxic Gas Mitigation

- Fire Protection: Water Wall

- Fogging

- Humidification

- Misting

BETE TF Spray Nozzles in Action

BETE Full Cone Spiral Spray Nozzles: BETE TF 112-150

BETE Full Cone Spiral Spray Nozzle: BETE TF 10 FCN

BETE Full Cone Spiral Spray Nozzle: BETE TF 40XP

BETE Extra-wide Full Cone Spiral Spray Nozzle: BETE TF 40-170

BETE Hollow Cone Spiral Spray Nozzle: BETE TF 40W