BETE Clog-Resistant Pigtail Nozzles Designed to Endure Limestone Slurry

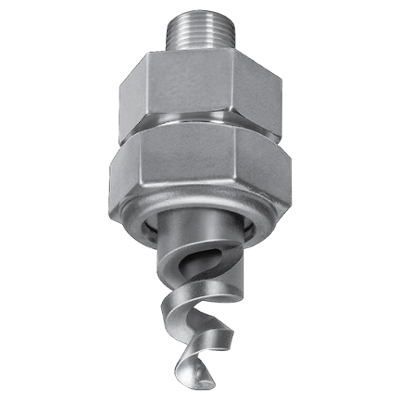

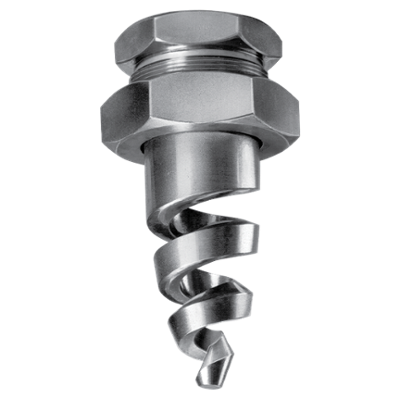

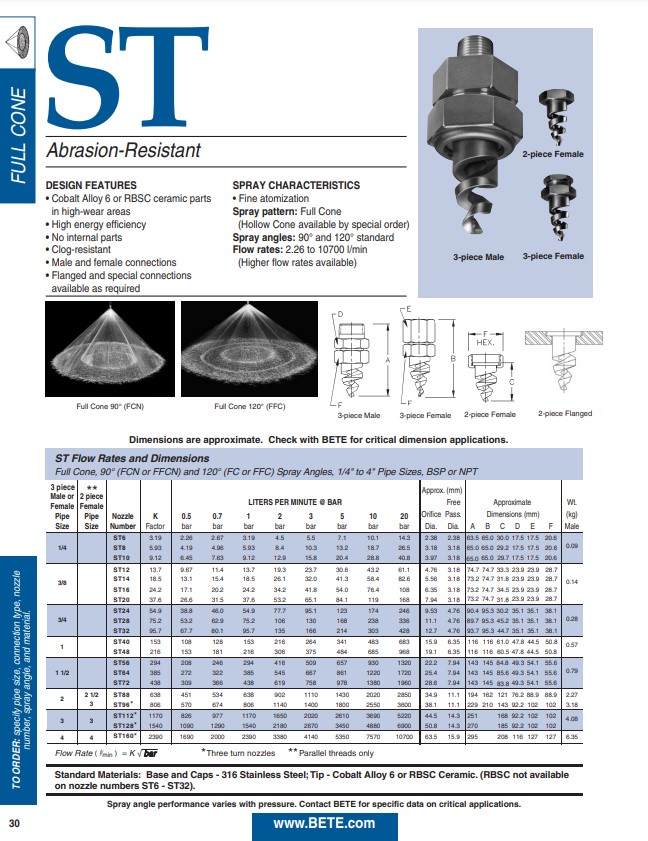

BETE ST spiral design remains one of the major advances in nozzle technology. The liquid is atomized into small droplets by a continuously descending spiral and, therefore, enters and exits with no internal restrictions through relatively large passages. The result is a higher discharge velocity so lower pumping pressures can be used to produce the required atomization.

Design Features of BETE ST Spiral Nozzles Design Features

- Designed for use with abrasive materials such as limestone slurry

- Extensive history as a wet FGD (flue gas desulphurization) absorber nozzle

- Available in Cobalt Alloy 6 or industrial ceramic (reaction bonded silicon carbide)

- Inherently clog resistant with no internal parts

- The spiral design produces a spray with more developed surface area than other nozzle styles for a given flow and pressure

- Designed by BETE, the inventor of the spiral nozzle

- Cobalt Alloy 6 or RBSC ceramic parts in high-wear areas

- High energy efficiency

- No internal parts

- Clog-resistant

- Male and female connections

- Flanged and special connections available as required

BETE ST Spiral Nozzles Spray Characteristics

- Fine atomization

- Spray pattern: Full Cone (Hollow Cone available by special order)

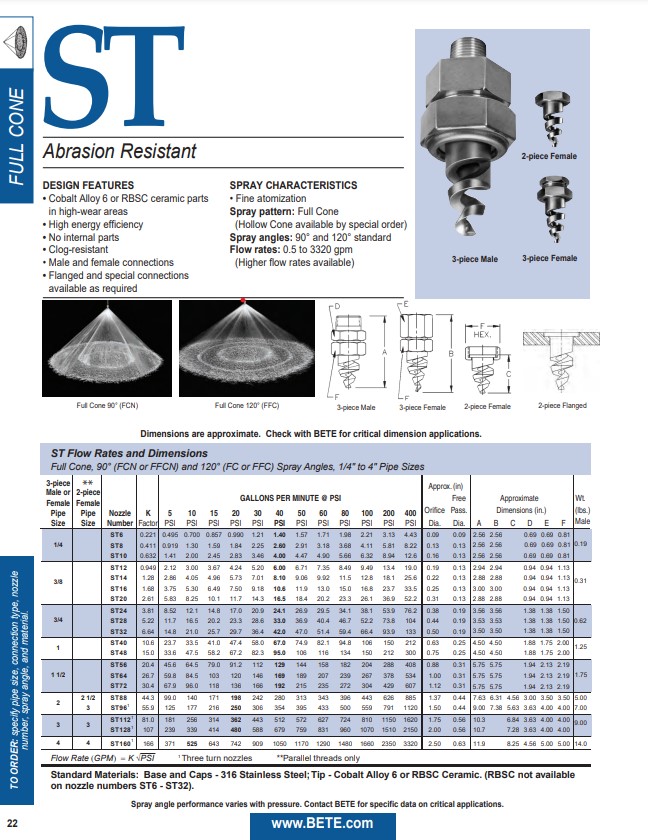

| Available Spray Angles | Flow Rate Range |

| 90 - 120° | 0.494 to 3710 gpm |

| Available Connection Types | Materials |

|

316 / Cobalt Alloy 6, 316 / RBSC |

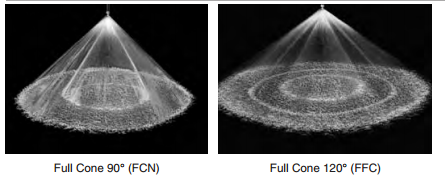

BETE ST Spray Angles

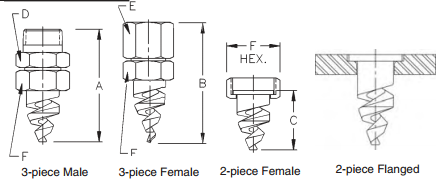

BETE ST Drawings

How Spray Pattern is Achieved on BETE ST Spiral Nozzles

- The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets surrounded by wider bands of relatively fine droplets.