BETE Hydropulse Spray Nozzles for precision and ease

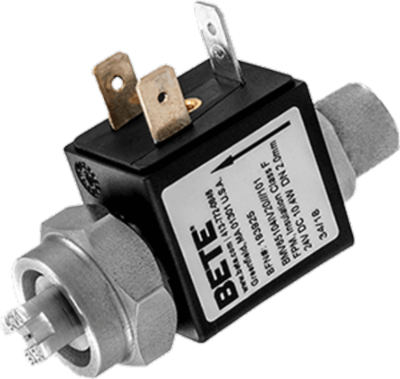

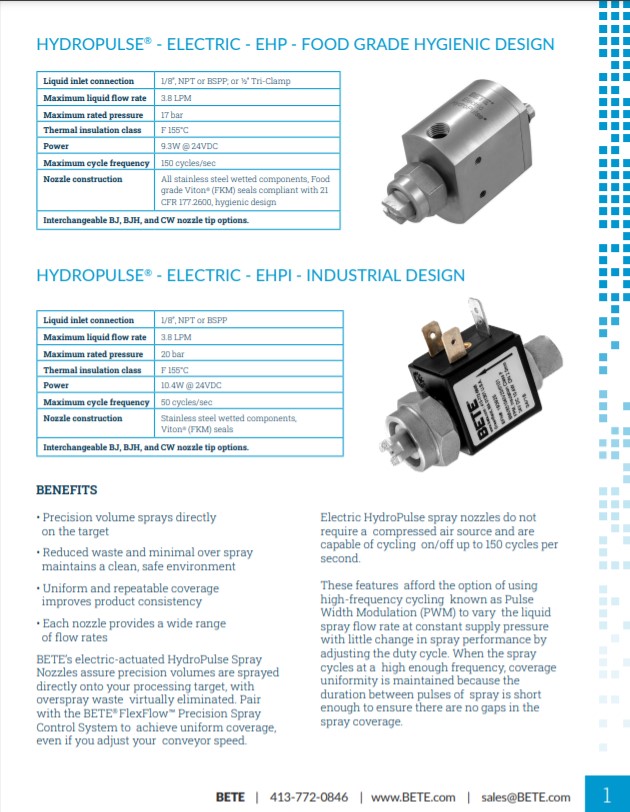

Introducing the NEW BETE HydroPulse® EHP | EHPI Electrically Actuated Automatic Precision Spray Nozzles and the FlexFlow™ Precision Spray Control System

VIDEO: BETE Electric HydroPulse® Automatic Precision Spray Nozzles – Hi-Speed Video Spray Demonstration

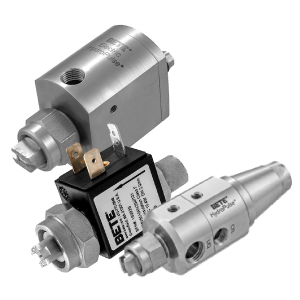

Bete HydroPulse HP Spray Nozzles – Low Flat Fan Spray Nozzle

The Bete HydroPulse (HP) is a direct pressure spray nozzle with an air actuated shut-off designed to replace current flat fan installations where an intermittent spray is desired. It is a more compact, lower cost, and easier to maintain solution than competitor models.

Key Features of the Bete HydroPulse HP Spray Nozzle:

- Food-grade materials of construction (303SS assembly) are ideal for food based applications as well as corrosive environments and harsh cleaning fluids.

- Simple and maintenance-friendly design allows for disassembly, inspection/cleaning, and reassembly with basic hand tools

- Internals can be removed in one simple operation!

- Can be rebuilt without uninstalling entire spray assembly

- Air Cylinders are not integrated and are easily replaceable

Design Features of the Bete HydroPulse HP Spray Nozzle:

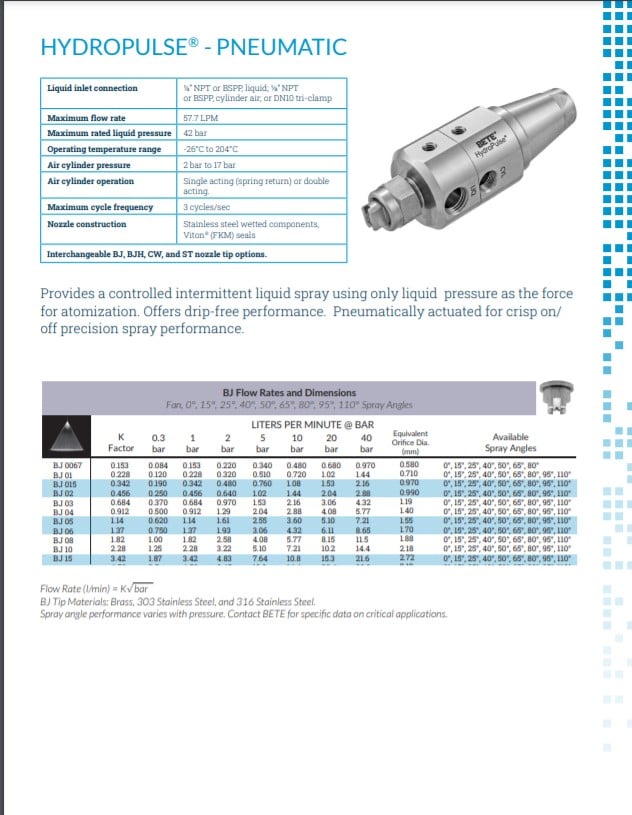

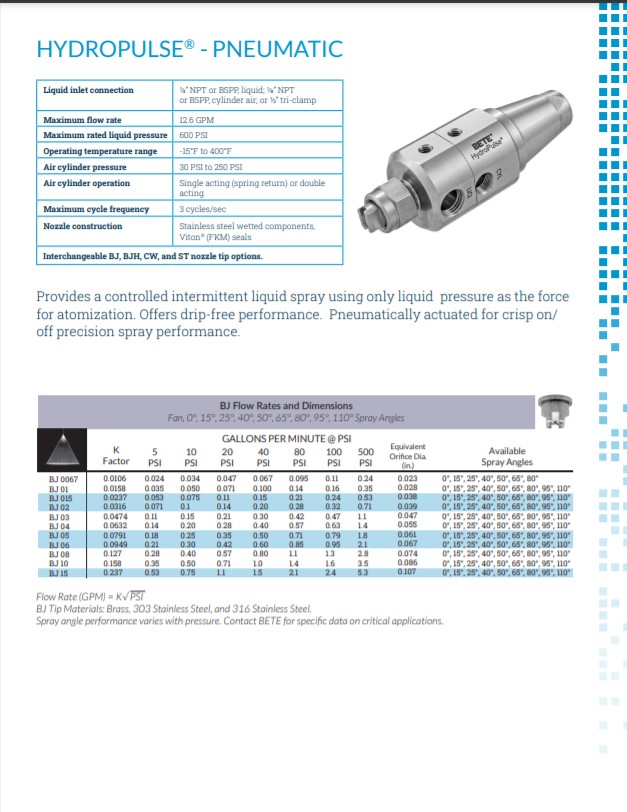

- Provides a controlled intermittent liquid spray using only liquid pressure as the force for atomization. Offers DRIP FREE performance.

- Interchangeable flat fan spray tips

- Pneumatically actuated for crisp on/off spray

- Straight through porting for fluid recirculation

- 303 SS assembly contains all foodgrade materials

- Variety of mounting brackets available

Spray Characteristics of the Bete HydroPulse HP Spray Nozzle

- Relatively coarse atomization Uniform distribution with tapered edges for use in overlapping sprays

- Spray Pattern: Flat Fan

- Spray Angles: 0° to 110°

- Flow rates: 0.003 to 24.7 gpm (0.011 to 101 L/min)

- Fluid Connection Size: 1/8, 1/4, Female, NPT/BSP Two fluid ports are standard; a plug to seal the recirculation port is included.

- Maximum Fluid Pressure: 600 psi

- Air Connection Size: 1/8 Female NPT; 1/8 Female BSP Adapter automatically included when fluid connection is BSP

- Air Cylinder Pressure: Minimum: 30 psi; Maximum: 250 psi. For larger BJ tips, more pressure may be required to break seal.

- Operating Temperature Range: -15° to 400°F. Nylon Mounting Hardware: 250°F MAX

- Standard Materials:

- Body: Nickel-plated Brass or 303 Stainless Steel

- Internals: PTFE, Viton, 303SS

- Air Cylinder: Stainless Steel, Anodized Aluminum, PTFE, and Viton®

- Fluid Seals: FDA-compliant Viton®

- Air Cylinder: Single-acting spring extend type. Air pressure retracts the rod and allows flow through the nozzle. Removing air pressure extends the rod and seals the nozzle. Double-acting cylinder available upon request

- Frequency Rating: Up to 180 cycles/minute, with an appropriate solenoid valve (Cv=0.08 minimum)