Are You Meeting SFCR Requirements?

As part of ongoing food regulatory initiatives, the Government of Canada has been taking action to strengthen Canada’s world-class food safety system with the Safe Food for Canadians Regulations. The Safe Food for Canadians Act consolidated 14 sets of Regulations into one. These Regulations implemented targeted improvements to the food system to overcome the risks and challenges posed by the speed, volume and complexity of present-day food production. The Regulations (SFCR) came into force on January 15, 2019.

The three main components of the SFCR are:

- Licensing,

- Traceability, and

- Preventative Controls

Furthermore, In the USA, the FDA Food Safety Modernization Act (FSMA) tasked food and beverage processors across the nation, including importers, to ensure their manufacturing equipment was compliant with various strict sanitation guidelines. Similar to the Canadian SFCR, the FSMA has elements that are focused on preventative controls and traceability.

Unfortunately, many operations continue to fall short of these sanitary standards.

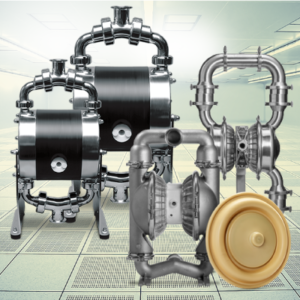

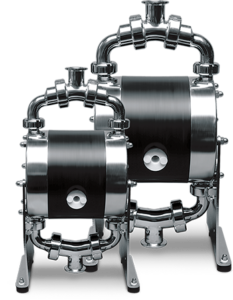

Wilden Saniflo Hygienic Series (HS) AODD Pumps and Pure-Fuse Diaphragms are the perfect combination for eliminating contamination and lowering the risk of a foodborne illness.

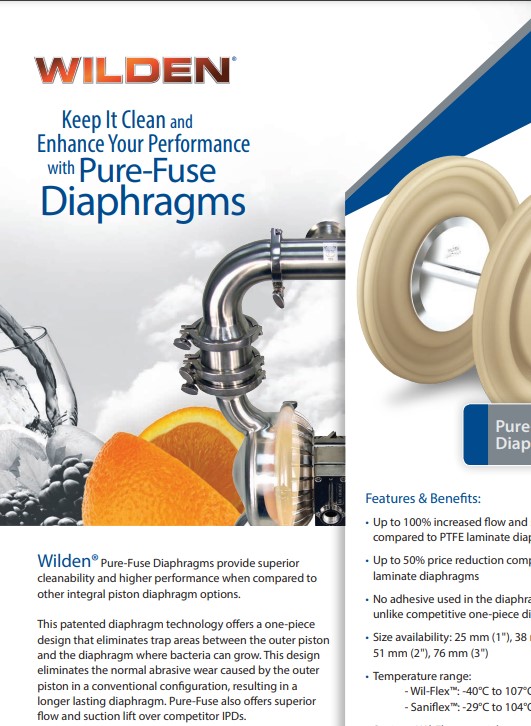

Wilden Saniflo Series Air-Operated Double-Diaphragm (AODD) Pumps and Pure-Fuse Diaphragms offer superior cleanability and higher performance, making them the perfect combination for hygienic applications. Patented Pure-Fuse diaphragms technology incorporates a one-piece design that eliminates product-trap areas between the outer piston and diaphragm that can harbor bacteria, a critical consideration for hygienic applications. This patented design also provides an unbroken fluid-contact surface for exceptional clean-in-place (CIP) capability and reduced contamination risks.

In addition to meeting or exceeding the highest standards in the industry such as 3-A, FDA CFR 21.177, 1935/2004/EC, USP Class VI, ATEX, and CE, Saniflo HS pumps provide significant operational advantages that enhance cleanability and efficiency, including:

- Free-Draining Flow Path optimizes performance and enables CIP capability while lowering the risk of cross-contamination or compromised finished product that may lead to costly recalls.

- Pure-Fuse Diaphragms one-piece design alleviates contamination concerns by eliminating product-trap areas that can harbour bacteria.

- Optional Swivel Stand for ease of maintenance, cleaning and faster changeovers between batches.

Hygienic Applications

- Food and Beverage

- Prepared Food and Sauces

- Poultry and Dairy

- Sweeteners and Acids

- Pharmaceutical and Cosmetics

Is Your Company Addressing your most Stringent Sterile Pumping Applications?

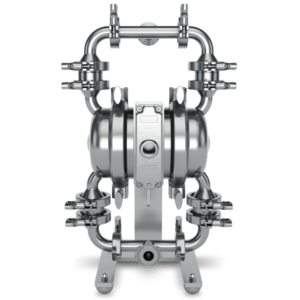

While manufacturers have a number of pump options that meet the stringent compliance requirements in the food, biotech and pharmaceutical industries, BIOCOR Series Air-Operated Double-Diaphragm (AODD) Pumps from Almatec provide significant operational and design advantages that make them the ideal choice for applications that require the highest level of sterile operation. They also provide superior containment, can be drained entirely without being disassembled or removed from the application, and incorporate housing parts containing no horizontal areas.

Almatec BIOCOR Series pumps are available in three sizes—B20, B32 and B40—with maximum capacities of 15, 34 and 70 gpm at a maximum discharge pressure of 100 psi. The B20 and B32 sizes feature a ball lifting system with magnets from the outside that ensures that the pump is drained completely without having to be dismounted, eliminating the need for mechanical ball-lifters that would be located in the wetted area.

How Can Almatec BIOCOR Pumps Help?

Almatec BIOCOR Series pumps help meet strict sanitary requirements. Their unique fluid path design with an integrated cleaning system enables clean-in-place (CIP) and sterilize-in-place (SIP). The BIOCOR design is also one that features no horizontal areas where products can get trapped. This design results in a pump that is EHEDG certified and conforming to EC1935/204, FDA, USP Class VI, and ATEX regulations.

Have a Fluid Handling Challenge? We can help you find a Pumping Solution.

John Brooks Company caters to diverse industries, offering suitable pump solutions for nearly all fluid handling needs - including yours! Our success hinges on fostering a collaborative partnership with you, where we help you find a tailored solution to enhance your systems, boost productivity, and minimize operational expenses.

Contact a John Brooks Company Pump expert today to help you determine the most suitable pump type for your application needs.