COPPUS Ventair TM High Pressure Centrifugal Blowers/Exhausters are rugged, high-volume, high-pressure centrifugal fans. Backwardly inclined fan blades yield stable air flow through small diameter or long runs of duct. The high static pressure capabilities make this an ideal air mover for supplying fresh air or source-capturing welding and other fumes for multiple remote locations with an optional multiple inlet adapters.

Features & Advantages of COPPUS Ventair TM High Pressure Centrifugal Blowers

- Heavy-gauge steel housing and base protects fan and motor

- Corrosion resistant silver powder coat suitable for marine environments

- Safety screens per OSHA; plated steel

- Lifting lugs

- Available in 1-, 2-, 5-, 15-, and 30-HP motors producing up to 10,700 cfm (18,179 m3/hr)

- One-piece, cast aluminum, spark-resistant, abrasion-resistant, dynamically balanced fan wheel

- Backward curved airfoil-shaped blades provide non-overloading power characteristics allowing peak performance through long runs of duct

- TE and EP Motors available in 115, 230, & 460 Volt

- Hazardous location (EP) motors rated NEC Class I, Division I, Group D & Class II, Division I, Groups F & G specifications

- 3,500 rpm motor directly connected to the fan wheel

- Variable outlet orientation

- 84 – 100 dBA @ 5 ft (1.5 m)

Options

- Multiple inlet Adapter

- Outlet Diffusers

- Starters & Cord

- Forklift Base

- Vibration Isolators

- Silencer Kit – 12 dBA reduction, mold resistant, flame resistant

COPPUS Ventair TM High Pressure Centrifugal Blowers Accessories

- Duct – 8”, 10”, 12”, 14” & 16”; Heavy Duty, Conductive, & Polyvinyl

- Duct Storage Canisters

Note: TM-5, TM-6, & TM-9 special order only.

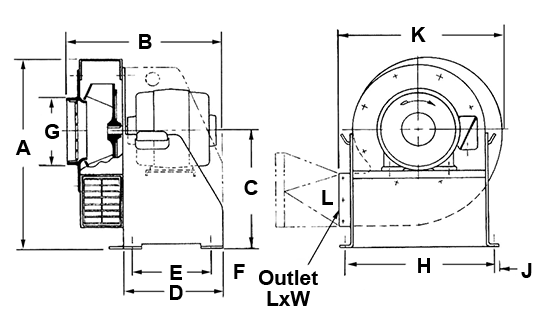

Dimensions

| Ventair | A | B | C | D | E | F | G | H | J | K | L | Net Wt. | ||||||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | lbs | kg | |

| TM-4 | 22.5 | 572 | 18.8 | 478 | 14.0 | 356 | 12.0 | 305 | 8.0 | 203 | 2.0 | 51 | 8.0 | 203 | 16.5 | 419 | 1.0 | 25 | 19.0 | 483 | 7.4 x 5.5 | 188 x 10 | 110 | 50 |

| TM-5 | 26.2 | 665 | 23.6 | 599 | 16.5 | 419 | 15.0 | 381 | 11.7 | 298 | 1.5 | 38 | 10.0 | 254 | 19.5 | 495 | 1.0 | 25 | 22.0 | 559 | 8.7 x 6.6 | 221 x 168 | 130 | 59 |

| TM-6 | 28.8 | 732 | 24.9 | 632 | 17.5 | 445 | 15.5 | 394 | 12.2 | 311 | 1.5 | 38 | 12.0 | 305 | 22.5 | 572 | 1.0 | 25 | 25.2 | 351 | 9.6 x 7.4 | 244 x 234 | 205 | 93 |

| TM-8 | 35.6 | 904 | 32.6 | 828 | 22.0 | 559 | 21.0 | 533 | 16.0 | 406 | 2.0 | 51 | 14.0 | 356 | 28.8 | 734 | 1.5 | 38 | 30.0 | 762 | 11.5 x 9.2 | 292 x 234 | 550 | 250 |

| TM-9 | 42.0 | 106.7 | 38.5 | 978 | 26.0 | 660 | 27.0 | 686 | 22.7 | 578 | 2.0 | 51 | 16.0 | 406 | 31.5 | 800 | 1.5 | 38 | 34.2 | 870 | 11.5 x 9.2 | 292 x 234 | 670 | 304 |

Performance

| PEROFRMANCE BY RPM | |||||||

| Ventair | Free Air | Static Pressure (WG) | Duct Size | ||||

| cfm | mm | cfm | mm | cfm | mm | ||

| TM-4 | 60 Hz (3,500 RPM) |

1,700 | 2,887 | 6.0 | 152 | 8.0 | 203 |

| TM-5 | 2,500 | 4,248 | 8.2 | 208 | 10.0 | 254 | |

| TM-6 | 4,100 | 6.966 | 12.7 | 323 | 12.0 | 305 | |

| TM-8 | 7,450 | 12,658 | 18.6 | 472 | 14.0 | 356 | |

| TM-9 | 10,700 | 18,179 | 24.2 | 615 | 16.0 | 406 | |

| TM-4 | 50 Hz (2, 850 RPM) |

1,417 | 2,406 | 4.0 | 102 | 8.0 | 203 |

| TM-5 | 2,083 | 3,540 | 5.6 | 142 | 10.0 | 254 | |

| TM-6 | 3,417 | 5,805 | 8.7 | 220 | 12.0 | 305 | |

| TM-8 | 6,208 | 10,548 | 12.6 | 320 | 14.0 | 356 | |

| TM-9 | 8,917 | 15,149 | 16.4 | 417 | 16.0 | 406 | |

| FREE AIR DECIBEL LEVEL | |

| TM-4 | 84 dBA |

| TM-5 | 88 dBA |

| TM-6 | 94 dBA |

| TM-8 | 100 dBA |

| TM-9 | 104 dBA |