Cooling towers work tirelessly to maintain optimal performance. However, the presence of airborne contaminants, impurities, and suspended solids in the tower's water supply can impact their effectiveness. This article discusses the importance of using LAKOS water filters in cooling towers. They can make things work better and more efficiently.

The Purpose of LAKOS Centrifugal Separators in the Cooling Process

Centrifugal separators remove unwanted solid or liquid impurities from the fluid in cooling systems, enhancing the system's performance and lifespan. These separators utilize centrifugal force to separate the undesired particles from the fluid, typically in a closed-loop cooling system.

The centrifugal separator directs the contaminated fluid into a rotating chamber or cone. The spinning creates a centrifugal force that pushes the heavier particles toward the sides of the separator. As a result, the separator's walls force the contaminants against them, forming a concentrated layer or sludge.

The purified liquid exits the separator through a central hole in the device. This occurs after eliminating the majority of impurities. From there, it circulates back into the cooling system to maintain the desired temperature.

Centrifugal separators keep the cooling system efficient by removing debris, sediment, and other impurities in the fluid. The separation process helps minimize the risk of clogging, corrosion, and fouling in heat exchangers, pipes, and other cooling system components.

This ensures efficient heat transfer, saves energy, and prolongs cooling equipment lifespan, enhancing the reliability and effectiveness of the cooling process.

Common Problems Found in Cooling Towers

Airborne contaminants like dust, sand, and pollen, drawn into the tower with outside air, mix with the water supply. Without effective filtration, these impurities become trapped in the water flow, leading to detrimental consequences. Cooling towers can experience various issues, such as corrosion, microbiological growth, and scale. These problems can lead to reduced performance and lifespan of the cooling tower.

Corrosion

Corrosion can occur due to aggressive water chemistries, such as high dissolved oxygen levels or low pH. It can lead to the degradation of metal surfaces, loss of structural integrity, and increased maintenance and repair costs.

The gathering of solids interferes with the effectiveness of water treatment in cooling tower basins that are less than 1/16”. When this happens, solids gather, allowing sulphate-reducing bacteria (SRB) to multiply.

This bacteria lower sulphate levels in the water, making it more acidic and causing under-deposit damage by converting sulphate into hydrogen sulphide.

This corrosion can decrease the lifetime of equipment by 75%.

Microbiological Growth

Cooling towers provide a favourable environment for the growth of microorganisms, including bacteria, algae, and fungi. If not adequately controlled, microbiological growth can cause fouling, corrosion, and health concerns. This is due to the cooling towers and evaporated coolers, obtaining a moist and warm environment.

This environment allows such bacteria to multiply and thrive, creating a biofilm. Living things make surfaces dirty and corrode cooling system parts. Biological activity leads to surface fouling, causing corrosion in the cooling system.

This can lead to health hazards such as legionella.

Scaling

Minerals and impurities in water create hard deposits on the cooling tower surfaces, known as scaling. Scaling is often due to the plating-out of Calcium Carbonate (CaCO3) on heat transfer surfaces.

The precipitation of dissolved minerals from cooling tower water creates these deposits. When calcium carbonate (CaCO3) interacts with silica and water, it forms a rigid, solid scale on heat transfer surfaces. This scale significantly hampers the system's heat transfer efficiency. Scaling is the primary cause of the frequent chiller tube cleaning and maintenance requirement.

LAKOS Filtration Solutions in Cooling Towers

LAKOS' advanced filtration prevents contamination by efficiently capturing and removing harmful impurities. These purposefully designed filtration units create optimal conditions for chillers, compressors, heat exchangers, and other equipment.

Benefits of Using LAKOS Water Filtration

LAKOS cooling tower filtration units have several benefits that transform the filtration landscape and help reduce the risk of corrosion, microbiological growth, and scale. Some of these benefits include:

- Reduces under-deposit corrosion, eliminates the nourishment for biological growth, and prolongs the basin's lifespan.

- Reduces the need for manual cleaning and maintenance, results in decreased downtime and mitigates the risk of injury.

- HydroBoosters efficiently eliminate suspended solids originating within the cooling tower basin.

- The system upholds the efficiency of heat transfer surfaces downstream, ensuring optimal thermal performance.

- Preserves the overall system efficiency, therefore conserving energy.

- Eliminates manual basin cleaning.

- Virtually eliminates under-deposit corrosion

- Minimizes downtime and maintenance

- Optimizes the effectiveness of water treatment programs

- Minimizes water loss

- Extended equipment life

Removal of Solids In Cooling Tower Systems

Solids removal is vital in cooling tower systems as it eliminates suspended solids and contaminants like sediment, debris, and rust particles. These impurities can impede performance, causing scaling, microbiological growth, and corrosion.

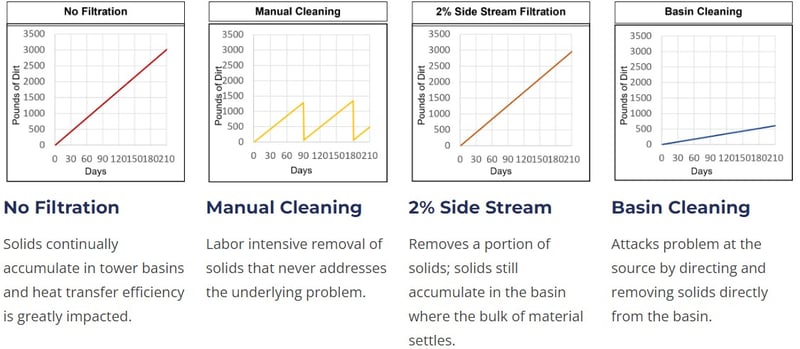

The diagram shows different ways to remove solids in cooling tower systems. The diagram illustrates various methods of eliminating solids in cooling tower systems. It depicts the outcomes of different scenarios: no filtration, manual cleaning, 2% side stream method, and basin cleaning to eliminate solids.

Investing in proper filtration unleashes a cascade of advantages. The continuous operation, reduced maintenance costs, safeguarded product quality, and extended equipment lifespan are just some benefits gained. LAKOS filtration strengthens cooling tower systems, protecting them from harmful effects and promoting reliable, efficient, and cleaner operations.

JOHN BROOKS COMPANY IS YOUR PRIME SOURCE FOR FILTRATION

John Brooks Company collaborates with renowned manufacturers to provide diverse filtration systems for various commercial, municipal, and industrial applications, including agriculture, food production, chemical, biogas, oil and gas, and mining.

Our experts can help you choose the right filtration system for your needs.

Contact us now to explore what we have to offer or speak to one of our specialists.