Easy to Use, Intelligent Rotary Lobe Pump

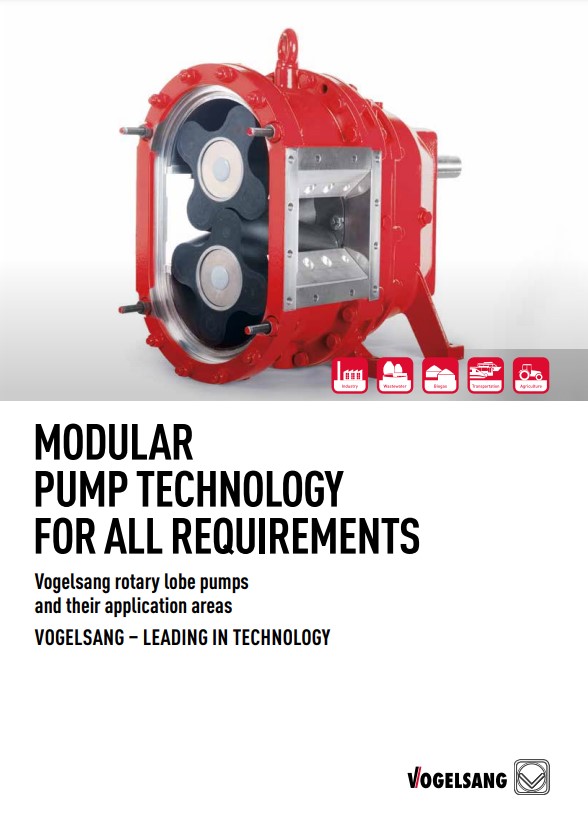

The IQ series is the intelligent rotary lobe pump for the industrial, waste water and biogas sectors. Like all other Vogelsang rotary lobe pumps, the IQ series is self-priming at depths of as much as 9 meters and it is resistant to dry running. The built-in InjectionSystem and the fluid buffer guarantee optimum suction that is not impaired even if the medium contains foreign matter. At the same time, the rotary lobe pumps in the IQ series are highly efficient, thanks to their computer-optimized design. The pump’s power is enhanced by low-pulsation conveying thanks to the Vogelsang HiFlo lobes and the ability to operate the pump in either direction. The compact design and the variable connecting parts in the IQ series allow you to install the pump in almost any position.

Vogelsang offers the IQ series in two model series:

- IQ112: The universal rotary lobe pump can be used in a variety of applications, pumping even highly viscous media or media containing foreign matter, at up to 78 m3/h and against pressures of up to 7 bar.

- IQ152: The powerful IQ152 pumps media at up to 154 m3/h against pressures of up to 7 bar in industrial applications, or in sewage treatment plants or sewers.

Besides the classic advantages of Vogelsang rotary lobe pumps, the IQ series also boasts excellent maintainability. The pumping chamber consists of a central part that provides access to all the important wear parts simply by removing the cover. The wear parts have been reduced by half in the IQ series, compared to conventional rotary lobe pumps. This not only saves on spare parts costs, it also saves up to 30% in maintenance work overall. In addition to the smaller quantity of wear parts, the pump does not have to be dismounted or disconnected from piping.

Maintenance of the VX Pump – How to Dismount an IQ Pump

1. Open the Pumping Chamber: Simply unfasten a few screws, remove the pump cover and you have free access to the rotary lobes. This makes it quick and easy to inspect both the lobes and the pump cover itself. If necessary, you can also replace the wear plate in the pump cover.

2. Dismount the Rotary Lobes: Unfasten the strain bolts, remove the pressure discs on the lobes. Then place the puller on the lobes and dismount them.

3. Remove the Wear Plates: After you have removed the lobes, all you have to do is remove two screws and you can remove the wear plate at the gearbox side.

4. Remove the Quality Cartridge mechanical seal: Using a simple pull-out device, you can now pull out the Cartridge Mechanical Seal and then replace it just as easily.

5. Assembly: Fix the wear plate at the gearbox side with two screws, install the lobes and fasten them on the shaft with pressure disks, fit the pump cover and screw it in place.

Vogelsang Rotary Lobe Pump IQ Series Applications

- Municipal Markets: The innovative design of the rotary lobe pumps in the IQ series is Vogelsang's answer to the all too familiar demand in the waste water sector: "Cut costs and increase efficiency". Whether used as a sludge pump in a sewage treatment plant, as a waste water pump in the sewer system or on tankers or disposal vehicles, Vogelsang rotary lobe pumps from the IQ series can be adapted to common installation scenarios quickly and easily thanks to their variable connector parts.