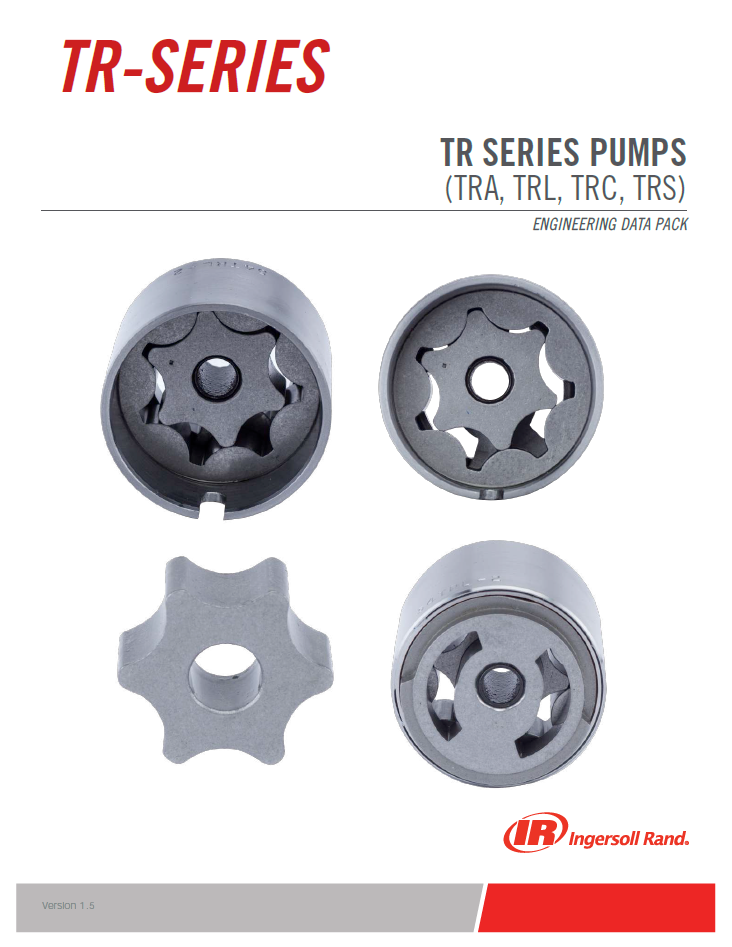

Ingersoll Rand (formerly Tuthill) TR Series Lubrication Pumps

The Ingersoll Rand TR Series is a unique design of lubrication pumps. As opposed to conventional pumps, the TR Series are a combination of parts that are fitted onto and driven by a shaft that is part of the equipment that requires lubrication. They have no body or separate shafts, only pumping elements and cover. This unique concept enables Ingersoll Rand to offer a very compact and economical method of installing a lubrication pump in OEM equipment. All the TR Series have the ability to reverse so irrespective of the shaft rotation the fluid delivery remains constant, in addition the floating plate is spring loaded and forms the back of the fluid chamber, this acts as a relief valve and can operate at pressures between 1.0 – 10 bar (14.7-147psi).

Description:

For Specifications please refer to the Engineering Data Pack.

Features & Benefits:

Shafts: Pumps can be fitted to both metric or imperial size shafts.

Compact: As the pump mounts directly on an existing shaft the only extra length is created by the torque ring and cover. In certain cases the porting can be incorporated within the body of the equipment it is being fitted to, therefore the cover can be omitted.

Automatic Reversing: In a non-reversing lobe or gear pump reversing the rotation of the shaft means the direction of flow changes. In the Ingersoll Rand TR pump the reversing mechanism ensures the direction of flow remains constant as the idler carrier revolves through 180 degrees as the direction of rotation changes. This feature is extremely important for gearbox and transmission applications where the shaft rotation can change frequently.

Automatic Pressure Relief: The thrust plate is held in place by a spring, which is located in a pocket in the shaft. This pocket is machined to a set depth, which gives a pre-determined tension on the spring, and these parts create the relief valve. When the pressure in the pump exceeds the set pressure the plate is forced back opening up the internal clearances, stopping the pump developing pressure. Immediately the pressure drops the plate returns to its normal position and the pumping action continues.

Through Shaft-Lubrication: The discharge of the pump can be split within the cover so flow can be directed up the centre of the shaft. This can be the total flow or a proportion of it with the remainder being directed through the normal discharge port. This through-shaft lubrication feature is especially useful when crankshaft journal bearings are being lubricated.

Pump Operation: All parts of the pump rotate except the cover and idler carrier. Driven by the rotor assembly the idler gear turns on the idler pin. The idler has one tooth less than the rotor gear with which it meshes and a pumping action is created. The idler carrier has openings for suction and discharge ports. It also has a pressed in idler pin to provide a journal for the idler gear. The idler carrier is machined so that the idler carrier assembly is free to rotate 180 degrees being stopped at each extremity by a pin located in the pump cover, this feature allows the suction and discharge port positions to remain constant regardless of the shaft rotation. The idler gear completes the pumping element and the floating plate centers the relief valve spring or plunger between the pump unit and drive shaft.

Applications:

- Lubrication