John Brooks Company is the exclusive distributor in Canada for BETE spray nozzles. BETE is a trusted international spray technology supplier for many corporations in the petroleum and petrochemical industries. Their extensive selection of standard nozzles meet the requirements of many applications, while custom development is available for specific customer needs. BETE's spray nozzle technology is first-in-class in reliability and durability for the harsh environments found in the Oil and Gas Industry. They offer a wide range of spray nozzles, injectors, lances and spraying systems in durable materials ideal for crude oil, abrasive media, corrosive reagents and extreme temperatures.

Common Nozzle Applications in the Petroleum & Petrochemical Industries:

CCR Lift Lines | Refinery Piping

DUR O LOK couplings are all-purpose lightweight connectors designed to replace standard pipe flanges.

- Compact and lightweight design can reduce the length and outside diameter by 30%-50% and weight by 60%-90% compared to standard flanges.

- Complete port design features a non-restrictive, smooth inner bore that reduces pressure drop.

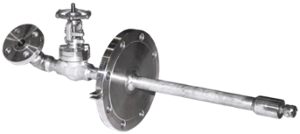

Chemical Injection Nozzles

Chemical Spray Injection Applications

- Inject various reactants, scavengers, inhibitors, or other chemicals throughout many processes

- Wash water injection nozzles are used at various points in the process of refining crude oil into its component fractions

- BETE can design a custom injection lance specific to your application ensuring proper fabrication, installation, and operation

FCC (Fluid Catalytic Cracking)

- Atomize crude oil feed using steam and inject into riser where it reacts with powdered catalyst

- Two-phase flow with high particulate count requires large free passage and homogeneous mixing

Fire Protection and Safety

Spray nozzles provide personnel and system protection throughout production and distribution from offshore drilling platforms to refining to storage tanks.

BETE offers nozzles for open-type fire protection systems:

- Open-Type Deluge

- Water Mist Systems

- Off-Shore Fire Suppression

- Water Wall Protection System

- Toxic Gas Mitigation

- The fine mist of water sprays can absorb toxic gases in the event of a leak.

Gas Cooling/Quenching

Gas Cooling Applications

- Nozzles for gas cooling or quenching in various petrochemical applications create stable conditions for downstream plant components’ safe and efficient operation.

Common applications:

- Cooling process gases prior to scrubber/baghouses

- Catalyst reformer gas cooling

- Cooling combustion exhaust gases

- FGD quenching

Gas Scrubbing

Gas Scrubbing Applications

- Scrubber nozzles are used to remove pollutants and other chemical contaminants from a process fluid.

- BETE offers nozzles for a wide variety of scrubbing systems.

- Open Towers

- Packed Towers

- Venturi Scrubbers

- NOX Removal (SCR/SNCR)

Tank Cleaning

Tank Cleaning Applications

- Tank cleaning is essential, especially when removing harsh chemicals and soils, which can be time-consuming and expensive without the correct solution.

- Optimize cleaning with BETE’s stationary, free-spinning rotational, and controlled rotational tank cleaning nozzles in the refining process:

- Process Vessels

- Rail Cars

- Reactors

- Storage Tanks

Torch Oil

- Apply heat to various processes, including FCC re-generators to heat catalyst by injecting light oil during start-up.

- Also used to control the rate of cooling during a shutdown.

- Fine atomization is a requirement for an efficient burn.

Vacuum Distillation

Vacuum Distillation Applications

- The petroleum industry uses vacuum distillation in many parts of the refining process to separate hydrocarbon fractions.

- Use nozzles to atomize the process liquid, increasing its exposed surface area to increase evaporation and separation efficiency.

- In vacuum towers, where the gas side pressure drop must be low, packing is often used instead of trays.

- Nozzles uniformly wet the packing, over which the gas flows and contacts the liquid

Waste Disposal

Evaporative Disposal Applications

- Spray wastewater to increase evaporation efficiency.

Waste Management Applications

- Injection of waste or by-products into an incinerator.

- Fine atomization is required to maximize surface area for these reactions.