Feedstock filtration solutions from John Brooks Company Limited are the preferred products in the oil and gas industry to maintain purity of feed streams. In the downstream processes, crude oil is processed into finished products for the market, reliable filtration with maximum efficiency is important. Our feedstock filtration solutions significantly lower production costs while helping to provide the highest quality, contaminant-free final product.

Naphtha, recycled hydrogen and other feed streams used in petroleum refining catalytic processes can become contaminated with iron oxide, pipe scale, and agglomerated semi-solids. These particulates can cause catalyst fouling and deactivation; plugged stream nozzles; degraded reactor efficiency; and failure to meet product specification.

Oil and gas filtration equipment from John Brooks Company Limited protect the catalyst in order to provide the greatest process efficiency and downstream equipment protection for processes such as –

• Hydrotreating

• Hydrocracking

• Catalytic reforming

• MTBE production

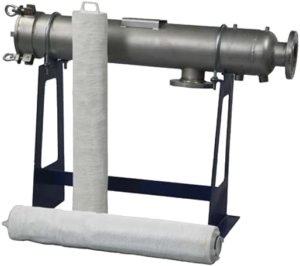

High quality and cleanliness of both the feedstock and the product are required for as low as possible production costs. Choose from our range of filter cartridges (reusable or disposable) and a range of filter housings to suit all budgets and production levels. We can supply individual components as well as the complete the filtration systems.