EXAIR's Super Air Knife™ is the most efficient compressed air knife on the market and our most popular design. It delivers a uniform sheet of laminar airflow across the entire length with hard-hitting force and the lowest operating cost. It is engineered to dramatically reduce compressed air usage while entraining ambient air at a ratio of 40:1. Noise levels are greatly reduced when compared to other blowoffs. Available from stock 3" to 108" long and made from aluminum, Type 303 stainless steel, Type 316 stainless steel and PVDF to meet your application needs. Custom sizes and materials available. EXAIR Air Knives offer an efficient way to clean, dry or cool parts, webs or conveyors as well as acting as an environmental separator or air curtain.

|

Product |

Length |

Material |

Includes Shim Set, Filter Separator, Pressure Regulator |

EFC Electronic Flow Control |

Plumbing Kit |

Air Knife Mounting System |

Air Inlet |

|

3" (76mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

3" (76mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

3" (76mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

3" (76mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

6" (152mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

6" (152mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

6" (152mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

6" (152mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

9" (229mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

9" (229mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

9" (229mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

9" (229mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

12" (305mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

12" (305mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

12" (305mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

12" (305mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

18" (457mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

18" (457mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

18" (457mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

18" (457mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

24" (610mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

24" (610mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

24" (610mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

24" (610mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

30" (762mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

30" (762mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

30" (762mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

30" (762mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

36" (914mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

36" (914mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

36" (914mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

36" (914mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

42" (1067mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

42" (1067mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

42" (1067mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

42" (1067mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

48" (1219mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

48" (1219mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

48" (1219mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

48" (1219mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

54" (1372mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

54" (1372mm) | PVDF | N/A | N/A | N/A | N/A | 1/4 NPT |

|

54" (1372mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

54" (1372mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

60" (1542mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

60" (1542mm | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

60" (1542mm | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

72" (1829mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

72" (1829mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

72" (1829mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

84" (2134mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

84" (2134mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

84" (2134mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

96" (2438mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

96" (2438mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

96" (2438mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

108" (2743mm) | Aluminum | N/A | N/A | N/A | N/A | 1/4 NPT |

|

108" (2743mm) | Type 303 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

|

108" (2743mm) | Type 316 Stainless Steel | N/A | N/A | N/A | N/A | 1/4 NPT |

Specifications:

Super Air Knife Performance |

||||||||

| Pressure Supply | Air Consumption per inch (25mm) | Velocity @ 6" (152mm) from target | Sound Level @ 3' (914mm) | Force per Inch (25mm) @ 6" (152mm) from target | ||||

| PSIG | BAR | SCFM | SLPM | FPM | M/S | dBA | OUNCES | GRAMS |

| 20 | 1.4 | 1.1 | 31 | 5,000 | 25.4 | 57 | 0.6 | 17 |

| 40 | 2.8 | 1.7 | 48 | 7,000 | 35.6 | 61 | 1.1 | 31 |

| 60 | 4.1 | 2.3 | 65 | 9,600 | 48.8 | 65 | 1.8 | 51 |

| 80 | 5.5 | 2.9 | 82 | 11,800 | 59.9 | 69 | 2.5 | 71 |

| 100 | 6.9 | 3.5 | 99 | 13,500 | 68.5 | 72 | 3.2 | 91 |

|

12" (305mm) Super Air Knife tested with .002" (0.05mm) thick shim installed. |

||||||||

Applications:

- Part drying after wash

- Sheet cleaning in strip mills

- Conveyor cleaning

- Part or component cooling

- Web drying or cleaning

- Environmental separation

- Pre-paint blowoff

- Bag opening/filling operations

- Scrap removal on converting operations

Advantages:

- Quiet - 69 dBA for most applications

- Minimal air consumption

- 40:1 air amplification

- Uniform airflow across entire length

- Variable force and flow

- No moving parts - maintenance free

- Easy mounting - compressed air inlets on each end and bottom

- Compact, rugged, easy to install

- Recessed hardware

- Stock lengths to 108" (2743mm) in aluminum, 303 stainless steel, and 316 stainless steel (ss - for temperatures up to 800°F (427°C), food processing or corrosive environments), and PVDF up to 54" (1372mm) for superior corrosion resistance.

- Special lengths available

- Unlimited system lengths of uninterrupted airflow available

Materials:

Aluminum - The aluminum Super Air Knife is suited to a wide variety of environments where corrosion or contamination is not a factor. The aircraft grade aluminum construction with plastic shim is very durable for general purpose applications. Stainless steel screws are used to eliminate corrosion in damp locations. It can withstand temperatures up to 180°F (82°C).

Type 303 Stainless Steel - This is the most common grade of stainless steel. It offers good strength and is best suited to mildly corrosive environments. It can withstand temperatures up to 800°F (427°C).

Type 316 Stainless Steel - Some applications require better corrosion resistance than offered by Type 303 stainless steel. Type 316 stainless steel offers excellent corrosion resistance, better strength properties and resists pitting. These factors are important to manufacturers of food, pharmaceutical and surgical products that need to minimize contamination by the metal. It can withstand temperatures up to 800°F (427°C).

PVDF (Polyvinylidene Flouridine) - EXAIR’s Super Air Knife is also available from stock in PVDF. PVDF offers superior strength and is resistant to UV light, inorganic chemicals, solvents, ozone, weather, fungi, chlorinated hydrocarbons, highly corrosive acids, weak bases and salts. The PVDF Super Air Knife uses PTFE shims, Type 316 Stainless Steel pipe plugs, and Hastelloy® C-276 alloy screws to withstand harsh environments. The PVDF Super Air Knife is suitable for manufacturing processes that involve electroplating, solar cells, lithium ion batteries, transfer of acids and caustic chemicals, brine, solvent recovery, semiconductors and medical devices. It can withstand temperatures up to 275°F (135°C).

Models:

The Super Air Knife provides the best performance with a 40:1 air amplification ratio, making it the most efficient. It is the best choice for all applications. The Super Air Knife has a laminar airstream that is uniform, forceful and quiet. Velocity is the highest of all three air knives. Air consumption is lowest of all three air knives. Compressed air inlets are provided on each end and on the bottom. Multiple Super Air Knives can be mounted “end to end” for longer lengths of uninterrupted airflow.

The Super Air Knife provides the best performance with a 40:1 air amplification ratio, making it the most efficient. It is the best choice for all applications. The Super Air Knife has a laminar airstream that is uniform, forceful and quiet. Velocity is the highest of all three air knives. Air consumption is lowest of all three air knives. Compressed air inlets are provided on each end and on the bottom. Multiple Super Air Knives can be mounted “end to end” for longer lengths of uninterrupted airflow.

The Standard Air Knife provides good performance with a 30:1 air amplification ratio that is less efficient than the Super Air Knife. It is a good choice when a less expensive alternative is required. The Standard Air Knife has an airflow that is also uniform and forceful. It is louder and uses more compressed air than the Super Air Knife. Compressed air inlets are provided on each end. Overall length is 1" (25mm) longer than the airflow length.

The Standard Air Knife provides good performance with a 30:1 air amplification ratio that is less efficient than the Super Air Knife. It is a good choice when a less expensive alternative is required. The Standard Air Knife has an airflow that is also uniform and forceful. It is louder and uses more compressed air than the Super Air Knife. Compressed air inlets are provided on each end. Overall length is 1" (25mm) longer than the airflow length.

The Full-Flow Air Knife provides good performance with a 30:1 air amplification ratio. The Full-Flow Air Knife is the least expensive and is a good choice for tight spaces. Force is less than the other two styles. Air consumption and sound level falls between that of the Super Air Knife and the Standard Air Knife. Compressed air inlet(s) are provided on the rear. Inlets are available on each end at a small additional charge, however they are not recommended for applications where uniform flow across the length is required.

The Full-Flow Air Knife provides good performance with a 30:1 air amplification ratio. The Full-Flow Air Knife is the least expensive and is a good choice for tight spaces. Force is less than the other two styles. Air consumption and sound level falls between that of the Super Air Knife and the Standard Air Knife. Compressed air inlet(s) are provided on the rear. Inlets are available on each end at a small additional charge, however they are not recommended for applications where uniform flow across the length is required.

Accessories:

Universal Air Knife Mounting System - The Model 9060 Universal Air Knife Mounting System is used to provide secure, precise positioning for any of the EXAIR Air Knives. The Air Knife can quickly and easily be moved within close proximity of the part to improve effectiveness. It can be mounted on either the top or bottom of most Air Knives (Super Air Knife, Standard Air Knife and Full-Flow Air Knife). The Universal Air Knife Mounting System has a durable, stainless steel construction that is suitable for a variety of industrial applications.

Universal Air Knife Mounting System - The Model 9060 Universal Air Knife Mounting System is used to provide secure, precise positioning for any of the EXAIR Air Knives. The Air Knife can quickly and easily be moved within close proximity of the part to improve effectiveness. It can be mounted on either the top or bottom of most Air Knives (Super Air Knife, Standard Air Knife and Full-Flow Air Knife). The Universal Air Knife Mounting System has a durable, stainless steel construction that is suitable for a variety of industrial applications.

The mounting system can also be used with EXAIR Static Eliminators. For the Super Ion Air Knife, it can be mounted on the top. Bottom mounting is possible on Super Ion Air Knives that are 18" (457mm) or longer. For the Standard Ion Air Knife, it can be top mounted on any length. Bottom mounting is possible on Standard Ion Air Knives that are 9" (229mm) or longer.

The Universal Air Knife Mounting System can be articulated into any position and provides a maximum extension of 30" (762mm). A 1/2" diameter hole is required for mounting. Alternatively, the bolt can be threaded directly into a 1/2"-13 tapped hole. For any style Air Knife that is 24" (610mm) to 54" (1372mm), use (2) Universal Air Knife Mounting Systems. For knives 55" (1397mm) - 71" (1803mm), use (3). For 72" (1829mm) - 95" (2413mm), use (4). For knives 96" (2438mm) and over, use (5).

Air Knife Plumbing Kits - Super Air Knives that are 24" or longer must be supplied with compressed air at multiple inlets on the knife. The Air Knife Plumbing Kits prevent you from searching for the right fittings or using undersized air supply lines. They provide properly sized compressed air hose or pipe, and fittings to interconnect the bottom or end compressed air inlets for best performance. Plumbing kits for aluminum Super Air Knives include a pressure gauge to monitor pressure at the Super Air Knife, which is an indication of proper air supply. They also include nitrile/PVC hose and brass fittings. Plumbing kits for stainless steel Super Air Knives include cut to length type 316 stainless steel pipe and fittings and will also work on PVDF Super Air Knives.

Coupling Bracket Kits - Some applications require a Super Air Knife that is longer than our 108" (2743mm) length. Coupling Bracket Kits that join two Super Air Knives together are available. The kit includes two rigid plates along with the assembly screws. The bottom plate is supplied with a hole to access the bottom compressed air inlets. All models include stainless steel screws.

Air Knife Shim Sets - Compressed air exhausts through a gap in the Air Knife which is set with a shim. Force and flow may be increased by adding shims.

Air Knife Shim Sets - Compressed air exhausts through a gap in the Air Knife which is set with a shim. Force and flow may be increased by adding shims.

Shim sets for aluminum Super Air Knives include a .001" (0.03mm) Amber color, .003" (0.08mm) Green color, and .004" (0.10mm) thick Tan color plastic shim . A Red color .002" (0.05mm) thick shim comes installed in the Super Air Knife. Shim sets for stainless steel Super Air Knives include (3) .002" (0.05mm) thick stainless steel shims. PVDF Super Air Knife shim sets include (3) .002" (0.05mm) PTFE shims.

How the Super Air Knife Works:

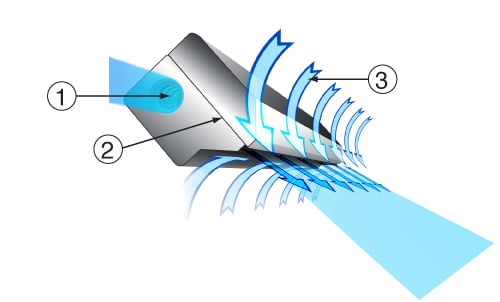

Compressed air flows through an inlet (1) into the plenum chamber of the Super Air Knife. The flow is directed to a precise, slotted orifice. As the primary airflow exits the thin slotted nozzle (2), it follows a flat surface that directs the airflow in a perfectly straight line. This creates a uniform sheet of air across the entire length of the Super Air Knife. Velocity loss is minimized and force is maximized as the room air (3) is entrained into the primary airstream at a ratio of 40:1. The result is a well defined sheet of laminar airflow with hard-hitting force and minimal wind shear.

Super Air Knife Standards and Certifications

EXAIR Air Knives comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.