Custom Spray Nozzle Solutions – Material Injection Coverage

Application #061070

Industry: Chemical Processing

Application: Material Injection

Product Description: Full Cone, Modified BETE XAAD Air Cap

Situation: A customer approached BETE asking if there was any way to improve the coverage out of an XA-type nozzle. They needed a very full cone spray in order to sanitize a container roughly the size of a ½ gallon (2 liter) milk carton. They had been offered several catalog solutions from competitors, but nothing was working.

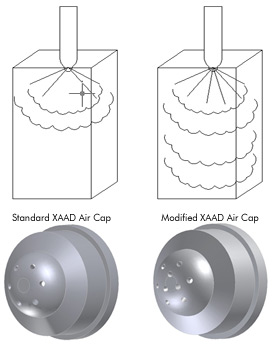

Solution: Full cone spray patterns are very difficult to generate with air atomizing nozzles. The droplet-laden air being ejected from an orifice can only expand so much after exiting. After this, the air will simply continue moving forward in a cloud without expanding further. This is why the BETE XAPR is a low angle (10-20°) spray.

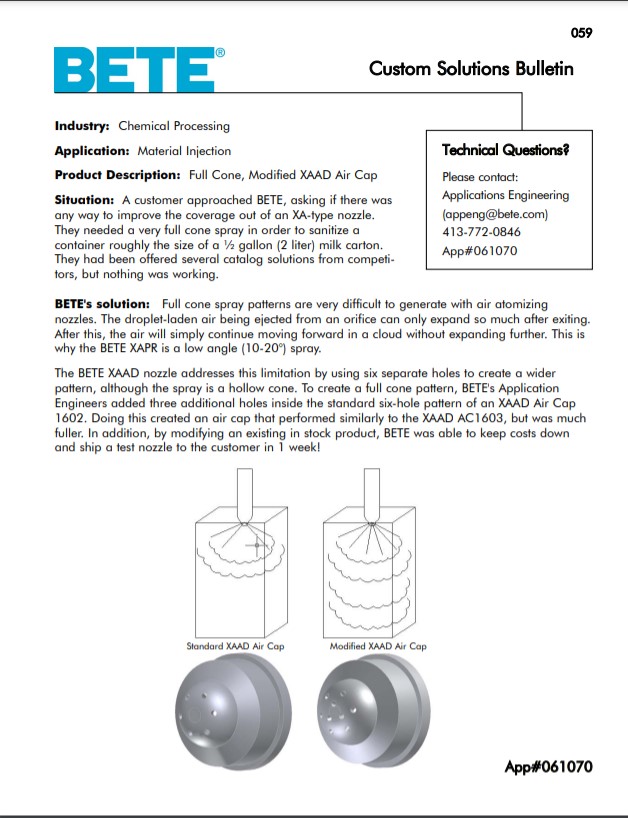

The BETE XAAD nozzle addresses this limitation by using six separate holes to create a wider pattern, although the spray is a hollow cone. To create a full cone pattern, BETE’s Application Engineers added three additional holes inside the standard six-hole pattern of an XAAD Air Cap 1602. Doing this created an air cap that performed similarly to the XAAD AC1603, but was much fuller.

Custom Spray Nozzle Solutions – Material Injection Coverage Drawings and Sketches