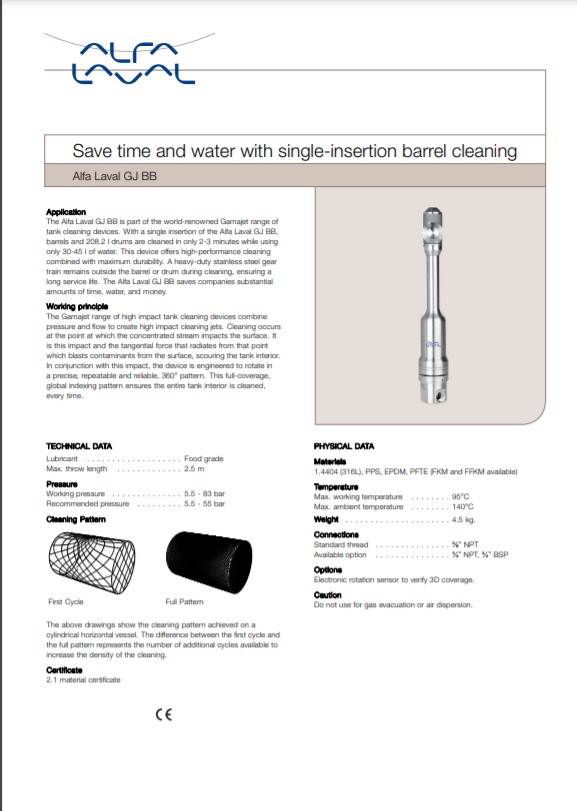

The GJ BB cleans your barrels right, the first time, faster and with less water – bung down.

The Alfa Laval Gamajet GJ BB combines high performance impingement with dramatically increased durability that provides a service life 3 times longer than the best existing cleaning machine. The fluid-driven Alfa Laval Gamajet GJ BB requires no external power supply and features the same impingement cleaning technology and performance as the widely recognized GJ 7 Barrel Blaster. It also combines heavy-duty stainless steel construction with a larger gear train (that remains outside the barrel during cleaning) to provide exceptional durability. With a single insertion you can achieve 100% cleaning effectiveness quick and easily. The GJ BB is easily attached to a Bipod mount for traditional bung hole down cleaning. A ball valve attached to the mount allows for convenient water control directly to the Bipod. Usable with all existing storage/rack systems, the GJ BB provides exceptional barrel cleaning convenience. Users can reliably clean barrels without ever lifting a barrel.

Features and Benefits:

- Cleans barrels and 55 gallon drums in 2-3 minutes

- Uses only 8-12 gallons (30-45l) of water per barrel/drum

- Heavy-duty, durable design

Technical Specifications:

Operating Range:

- Pressure: 100 to 1000 PSI (6.89 to 68.9 bar)

- Temperature: 32° to 190°F (0° to 87.78°C)

- Flow Rate: 3 to 8 GPM (11.35 to 30.28 l/min)

- Cleaning Radius: 2.5′ (0.76 Meters)

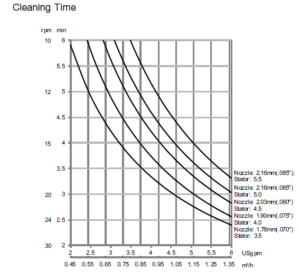

- Wash Cycle Time: 2-4 Minutes

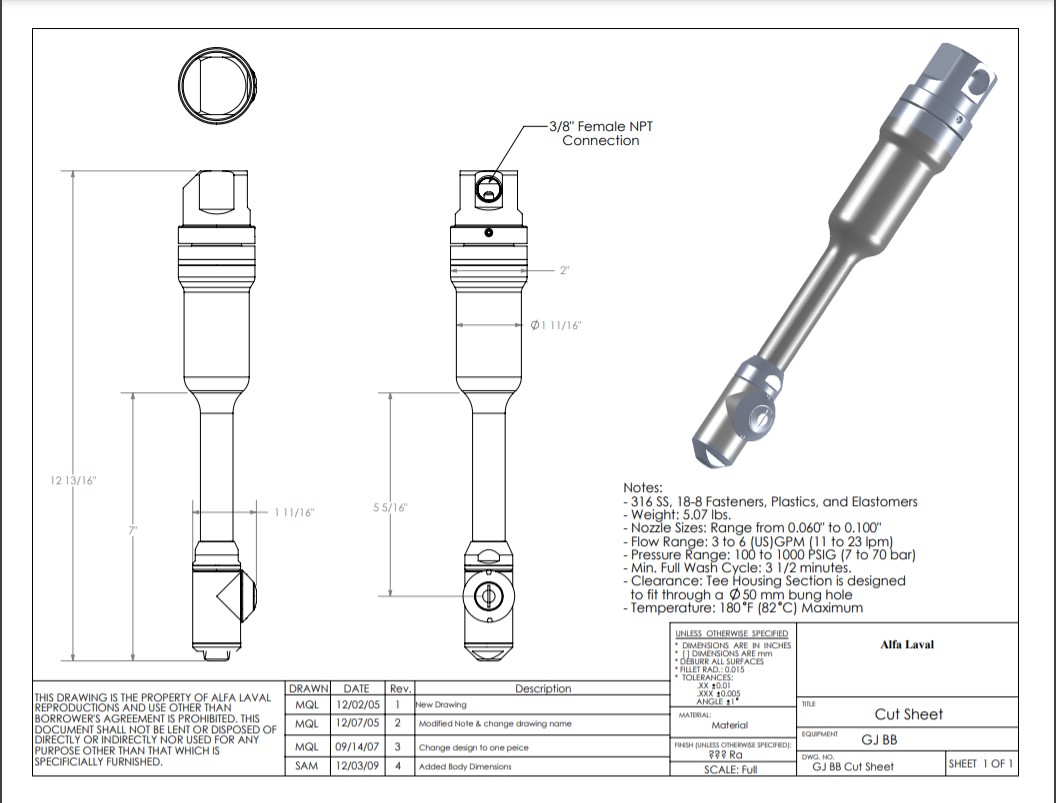

Overall Dimensions:

- Height: 12.75″ (323.85 mm)

- Body Diameter: 1.70″ (43.18 mm)

- Weight: 5.5 lb (2.49 kg)

- Clearance: 2″ (50.8 mm)

Other Options:

- Straight ¾” NPT or BSP inlet collar

|

|

|

Other Specifications:

| Inlet Connection: | 3/8 in. NPT-Female |

|---|---|

| Construction/Design: | Parts are machined from 316-L stainless steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the input shaft is plasma-sprayed with a chromium oxide coating on stainless steel. |

| Shaft & Gearbox Bushings: | Turbine shaft thrust is supported by a tungsten carbide bushing. Gear bushings are carbon filled polyphenylene sulfide. |

| Elastomers: | O-ring materials are selected for each application. EPDM is standard, with Kalrez® and Viton® available. Other materials can be supplied on special order. |

| Dynamic Seals and Bearings: | Rotary shaft and housing seals/bearings are made from carbon-filled-reinforced polyphenylene sulfide for extra-long wear and protection against leakage, abrasion and deposit build-up. |

| Nozzles: | Standard nozzle sizes are 0.070 in. (1.7 mm) 0.075 in. (1.9 mm), 0.080 in. (2.0 mm) and 0.085 in. (2.2 mm). Other nozzle sizes are available upon request. |

| Drive Mechanism: | The wash fluid enters the GJ BB at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the drive or rotor shaft. The bottom of this shaft is connected to the inside of a sealed, robust planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The sealed planetary gearhead has an external casing made of steel, surface-anodized for corrosion resistance. This sealed gearhead is located inside the gearbox, which itself is sealed, and thus does not require any lubricant. All internal gearhead parts are hardened sintered steel. |

| Lubricant: | Food grade grease is inside the sealed gearhead casing. |