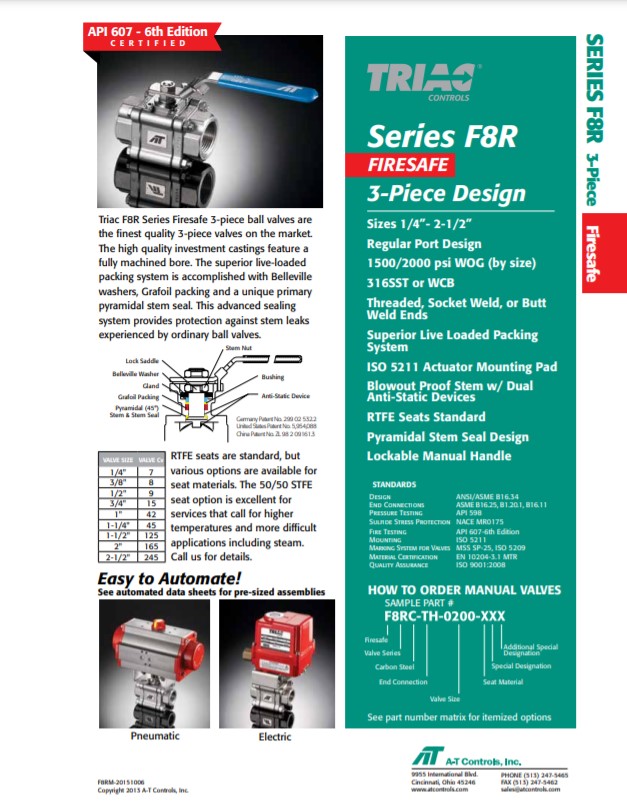

A-T Controls Triac F8R Series Fire-Safe 3-Piece Manual & Automated Ball Valves

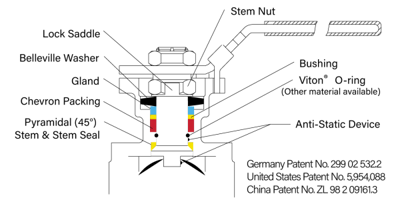

A-T Controls Triac F8R Series 3-Piece Ball Valves are the finest quality 3-piece valves on the market. The high quality investment castings feature a fully machined bore. The superior live-loaded packing system is accomplished with Belleville washers, “V” ring packing and a unique primary pyramidal stem seal – see drawing below. This advanced sealing system provides for protection against stem leaks experienced by ordinary ball valves.

|

Fire-Safe 3-Piece Manual Ball Valve Features:

- Regular Port 1500/2000 psi WOG (by size)

- Stainless or Carbon Steel Body

- Threaded, Socket Weld or Butt Weld

- Sizes 1/4″ – 2-1/2″

- Belleville Washers, Double Chevron Packing, RTFE Seats Standard

50/50 Seats Optional for High Temps

Reinforced TFE seats are standard, but various options are available for seat materials. The 50/50 seat option is excellent for services that call for higher temperatures and more difficult applications including steam.

A-T Controls Triac F8R Series High Performance 3-Piece Automated Ball Valves

- Pneumatic Spring Return Actuator

- Double Acting Actuator

- Electric Actuator

Manual Ball Valve Part Number Matrix

| HOW TO ORDER MANUAL VALVES (ie. ATC-F – 88 C – TH – 0150 – XXX) |

||||||||

| 1 | – 2 | 3 | – 4 | – 5 | – 6 | 7 | 8 | 9 |

| ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ |

| ATC-F | – 88 | C | – TH | – 0150 | – X | X | X | |

1 Prefix |

4 End Connection |

|||

| ATC-F | Fire Safe Tested | TH | NPT Ends | |

| ATC-F | (on 31 Series) Graphite Packing & Seals | SW | Socket Weld Ends | |

| ATC-T | (on 31 Series) TFM Packing & Seals | BW | Butt Weld Ends | |

| ATC-NS | NSF 61 & 372 Certified Series | EW | Extended Butt Weld Ends | |

| F1 | 150# Flanged Ends | |||

2 Valve Series |

F3 | 300# Flanged Ends | ||

| 10 | 1pc. Regular Port 2000 WOG | F6 | 600# Flanged Ends | |

| 20 | 2pc. Full Port 1000 WOG | FR | 600# RTJ Flanged Ends | |

| 21 | 2pc. Regular Port 2000/1500 WOG | SA | Sanitary Clamp Ends | |

| 22 | 2pc. Direct Mount 1000 WOG, Full Port | SF | Sanitary Clamp Ends w/ Cavity Filler | |

| 23 | 2pc. 3600 WOG, Seal-Welded | DA | Tube O.D. Ends | |

| 24 | 2pc. 3000 WOG | DF | Tube O.D. Ends w/ Cavity Filler | |

| 26 | 2pc. 6000 WOG, Seal-Welded | DS | Sanitary Clamp x Tube O.D. Ends | |

| 30 | 3-Way Flanged, Full Port | TE | NPT x Extended Butt Weld | |

| 31 | 3-Way Flanged, Direct Mount, Full Port | TS | NPT x Socket Weld | |

| 33 | 3, 4, 5-Way Full Port, Multiport | MF | Male NPT x Female NPT | |

| 38 | 3-Way NPT, Regular Port | Tube Socket Weld | ||

| 55 | 3pc. 1000/800 WOG, Full Port | W1 | 150# Wafer | |

| 77 | 3pc. 1000/800 WOG, Full Port, Sanitary | W3 | 300# Wafer | |

| HP | 3pc. Forged High Purity | W6 | 600# Wafer | |

| H78 | 3pc. Cast High Purity, Encapsulated Bolts | |||

| 83 | 3pc. 2000/1500 WOG, Full Port |

5 Valve Size |

||

| 8R | 3pc. 2000/1500 WOG, Regular Port | 0025 | 1/4″ | |

| 88 | 3pc. Direct Mount 2000/1500/1000 WOG, Full Port | 0038 | 3/8″ | |

| R8 | 3pc. Direct Mount 2000/1500 WOG, Regular Port | 0050 | 1/2″ | |

| 90 | 2pc. Flanged Full Port (Investment Cast) | 0075 | 3/4″ | |

| 91 | Unibody Regular Port Flanged | 0100 | 1″ | |

| 93 | 2pc. Flanged Full Port (Sand Cast) | 0125 | 1-1/4″ | |

| V7 | 3pc. Sanitary, V-Port | 0150 | 1-1/2″ | |

| V8 | 3pc. V-Port | 0200 | 2″ | |

| V9 | Flanged V-Port | 0250 | 2-1/2″ | |

| D9 | Direct Mount Flanged | 0300 | 3″ | |

| T5 | Tank Bottom 3pc. | 0400 | 4″ | |

| C8 | Cryogenic 3pc. Full Port | 0600 | 6″ | |

| CR | Cryogenic 3pc. Regular Port | 0800 | 8″ | |

| DR | 3-Way Bottom Entry Diverter Valve | 1000 | 10″ | |

| LB | PFA Lined Split Body Flanged Ball Valve | 1200 | 12″ | |

| P1 | Schedule 10 Piggable Valve | |||

| MU | Metal Seat Unidirectional Shutoff, Floating Ball |

6 Seat, Lining & Trim Materials |

||

| MB | Metal Seat Bidirectional Shutoff, Floating Ball | X | Reinforced TFE Seats (RTFE) | |

| MS | Metal Seat Scraper Seat Design | P | Virgin TFE (PTFE) | |

| MX | Metal Seat 3 pc. Bidirectional, Floating Ball | U | UHMWPE Seats | |

| M3 | 3-Way Metal Seat | D | Delrin® | |

| VS | Segment V-Port, Soft | S | 50/50 STFE Seats | |

| VM | Segment V-Port, Metal Graphite Packing | C | 25% CS Powder/ 75% TFE Seats (CTFE) | |

| VV | Segment V-Port, Metal Viton® Packing | T | TFM™-1600 | |

| WB | Block and Bleed Isolation Valve, 2000 WOG | F | TFE Cavity Filler | |

| W6 | Block and Bleed Isolation Valve, 6000 WOG | K | PCTFE (Cryogenic) | |

| L | PFA Lined w/ PTFE Seats | |||

3 Body Material |

M | MG1241 | ||

| Blank | No Designation=SST Body and Trim | Z | PEEK | |

| A | Alloy 20 | 2 | Tungsten Carbide Coated 316 SST Seats & Ball | |

| C | Carbon Steel Body | 3 | HCr Coated Ball/Stellite® Inlay Seats | |

| L | Low Carbon 316L Stainless Steel | 4 | Chrome Carbide Coated 316 SST Seats & Ball | |

| J | Low Carbon 304 Stainless Steel | 8 | Inconel® 718+CrC | |

| H | Carbon Body /Hastelloy Ball & Stem | |||

| Q | Carbon Steel Body/Monel Ball & Stem |

7 Special Designation |

||

| R | 316 SST Body/Monel Ball & Stem | X | No Specials | Series Standard | |

| T | Hastelloy C-276 Body & Trim | G | Gear Operator | |

| E | Electropolished Stainless Steel | L | Lockable Handle (HP Series) | |

| Z | Epoxy Coated Carbon Steel | R | Regular Port Valve | |

| D | CD3MN Duplex SST | O | Oval Handle (Available on Some) | |

| G | CE3MN Super Duplex SST | S | Spring Return Handle (Direct Mount Only) | |

| 2 | F316L (SF4) Electropolished Forged | |||

| 3 | CF3M (SF4) Electropolished Cast | |||

| 4 | F316H Forged | |||

| 5 | LCB | |||

| 8 | LCC | |||

| 6 | WC6 | |||

| 9 | WC9 | |||

8 Additional Specials |

9 Special Designation |

|||

| X | No Specials | Series Standard | Blank | No Designation, SST Stem | |

| O | Oxygen Cleaned | 3 | 30° V-Port (V-ball) | |

| Z | Special End Configuration | 6 | 60° V-Port (V-ball) | |

| V | Vented Ball | 9 | 90° V-Port (V-ball) | |

| E | Bonnet Extension Lockable Handle | A | A 17-4 PH® Stem | |

| F | Fugitive Emissions Bonnet | B | XM-19 (Nitronic 50) Stem | |

| D | Degreased & Bagged | C | Duplex 2205 Stem | |

| D | Inconel® 718 Stem | |||

| L | L-Port 3-Way Arrangement | |||

| T | T-Port 3-Way Arrangement | |||

| K | FFKM O-Ring (31 Series) | |||

| X | No Specials, Standard (HP/H78 Series) | |||

| S | Anti-Static Option (HP/H78 Series) | |||

.png)