3M High Flow HFM Series Filter Cartridges are high flow capacity, high efficiency, outside to inside flow direction liquid filtration cartridges designed for applications with large flow or contaminant removal requirements.

3M High Flow HFM Series Cartridges are for use in filter housings that accept the standard 3M High Flow filter cartridges.

The large diameter, pleated depth media cartridge design permits higher flow rates than standard 2.5” diameter filter cartridges resulting in significantly fewer required filter cartridges for a given flow.

The 5 micron (nominal) rated HFM Series Cartridges utilize a 3M polypropylene microfiber media specifically designed for use in process fluid applications containing organic and/or biological contaminants. The media design helps prevent premature blinding of the filter’s outer surface promoting fuller utilization of the media resulting in an optimum combination of particle removal efficiency and contaminant holding capability.

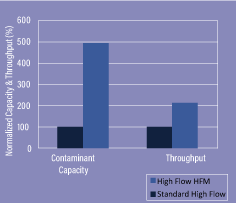

Figure 1 shows test results from challenging the High Flow HFM Series filter cartridge and the standard comparable efficiency High Flow filter cartridge with a surface (lake) water. Surface waters tend to contain high levels of biological and organic contaminants which have a tendency to foul surface filters. The results showed that, on average, the 3M High Flow HFM Series filter cartridges provided over twice the lifetime and held approximately five times the contaminant amount (by weight) versus the standard High Flow filter cartridge, while having similar initial particle removal efficiencies for particles larger than 5 micron.

3M microfiber media is pleated in a radial design which optimizes the usable surface area of the filter cartridges. 3M High Flow HFM Series Filter Cartridges utilize polypropylene end caps, outer sleeve and core to help protect the pleat structure integrity and provide a robust filter construction.

3M High Flow HFM Series Filter Cartridges Applications

- Process Waters

- Injection & Produced Waters

- Ground/Reclaimed/Waste Waters

- Machine Coolants

- Pre-RO Water

- Boiler Condensate

- Refining (Amine, Final Product…)

3M High Flow HFM Series Filter Cartridges Features & Benefits

Higher Flow Capability per Cartridge (vs. conventional 2.5” diameter cartridges)

- Fewer cartridges required, resulting in:

- Reduced cartridge handling

- Less individual cartridge seal points reducing chance of fluid bypass

Radial Pleat Design

- High contaminant capacity

Use of Specially Designed 3M Microfiber Filtration Media

- Helps prevent premature media blinding due to organic/biological contaminants

- High particle removal efficiencies throughout filter life

Easy to Use

- No special tools or hardware required for filter change-out

All Polypropylene Filter Construction

- Broad chemical compatibility

FDA Compliant

- Compatible in applications requiring direct food contact in food and beverage processing per 21 CFR