Pulsafeeder Peristaltic Metering Pumps Improve Boiler Efficiency

How We Stopped Scale Build-Up in Boiler Tubes with Pulsafeeder Chem-Tech XP Series Peristaltic Metering Pumps

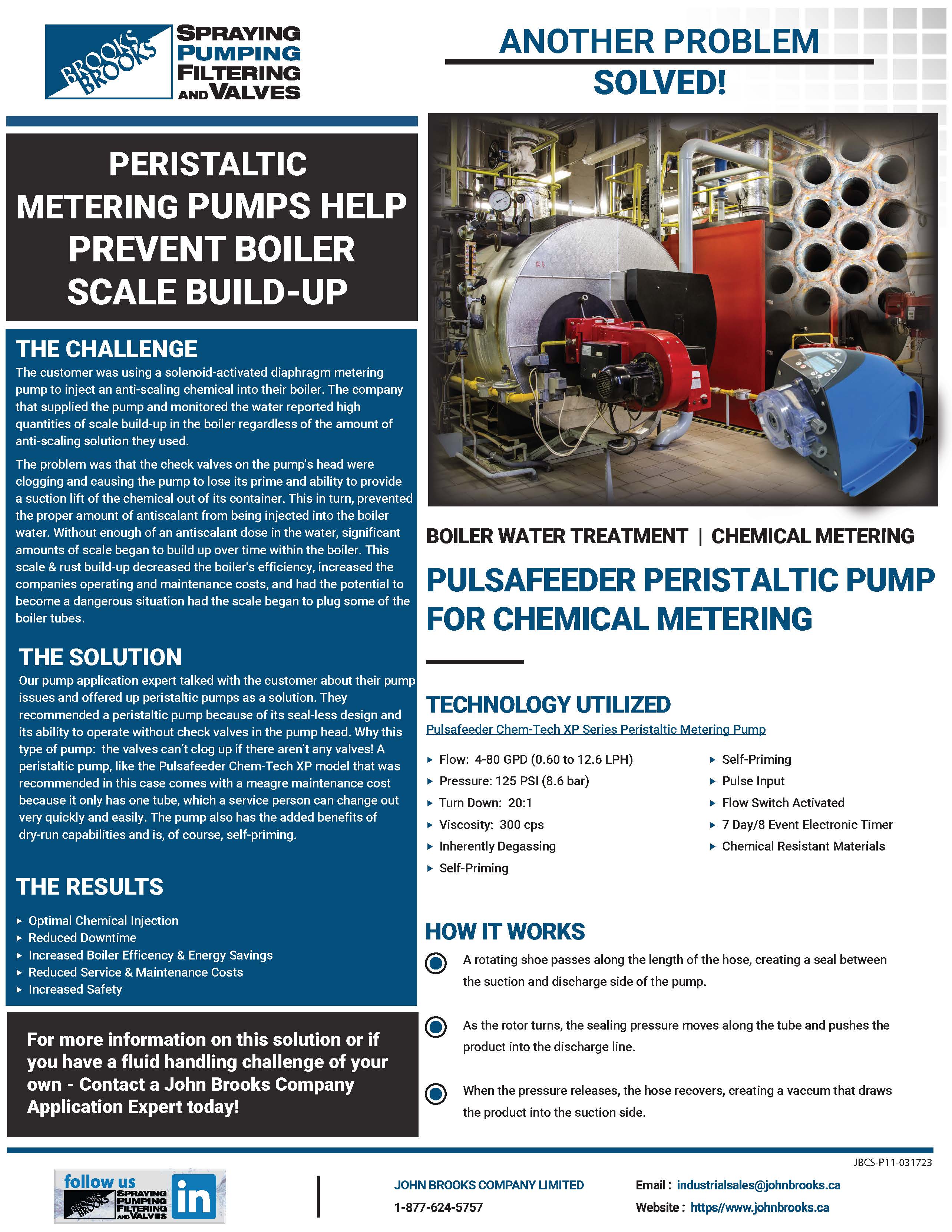

The Challenge

The customer used a solenoid-activated diaphragm metering pump to inject an anti-scaling chemical into their boiler. The Company that supplied the pump and monitored the water reported high quantities of scale regardless of the amount of anti-scaling solution they used.

The problem was that the check valves on the head of the pump were clogging, causing the pump to lose its prime and ability to provide a suction lift of the chemical out of its container. The lack of suction, in turn, prevented the proper amount of antiscalant from being injected into the boiler water. Without enough of an antiscalant dose in the water, significant amounts of scale began to build up over time within the boiler. This scale & rust build-up decreased the boiler's efficiency and increased the companies operating and maintenance costs and had the potential to become a dangerous situation had the scale begun to plug some of the boiler tubes.

Why is scale build-up a big problem in boiler tubes?

Any scale build-up in boiler tubes narrows the pipe diameter and decreases the proper flow of water throughout the boiler. There can't be an optimal heat transfer with a reduced flow, which leads to lower heating efficiency and fuel wastage and could, if left unchecked, create a dangerous situation should the tubes become clogged entirely.

For example, a scale build-up of as little as 4.3 mm causes around a 20% decrease in efficiency and inflates the operating costs of the boiler.

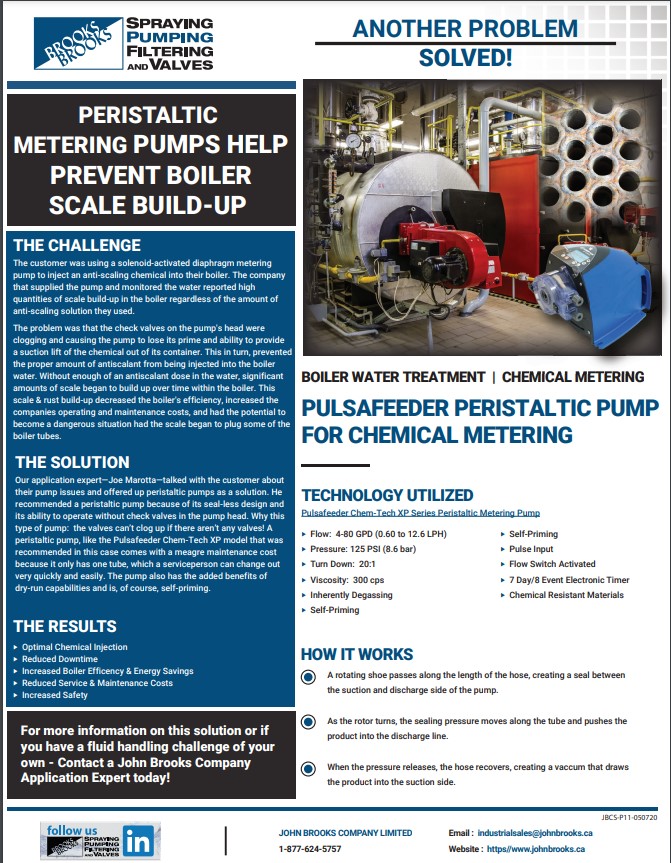

The Solution

Our pump application expert talked with the customer about their issues and offered peristaltic pumps as a solution. They recommended a peristaltic pump because of its seal-less design and ability to operate without check valves in the pump head: Why this type of pump: the valves can't clog up if there aren't any valves! A peristaltic pump, like the Pulsafeeder Chem-Tech XP model recommended, comes with a low maintenance cost because it only has one tube, which a serviceperson can change quickly and easily. The pump also has the added benefits of dry-run capabilities and is, of course, self-priming.

The Result

With the pump managing to tackle each of the customer's pain points, the results were remarkable, including:

- Optimal chemical injection

- Reduced service & maintenance costs associated with the boiler

- Reduced downtime

- Increased boiler efficiency & energy savings

- Improved safety

In terms of the customer's return on investment (ROI), if we only consider the cost of a maintenance person coming in to unclog or replace valves every month at around $100 – $150 per hour, then, based on the price of the new pump, they saw a positive ROI in under ten months. When factoring in the other benefits, such as fuel savings and better boiler efficiency, the ROI is, in fact, much quicker.

Technology Used

We used Pulsafeeder Chem-Tech XP Series Peristaltic Metering Pump to solve the customer's problems.

Pulsafeeder Chem-Tech XP Series Specs:

- Flow: 4 – 80 GPD (0.60 to 12.6 LPH),

- Pressure: 125 PSI (8.6 bar)

- Turn Down: 20:1

- Viscosity: 300 cps

- Inherently Degassing

- Self-Priming

- Pulse Input

- Flow Switch Activated

- 7 Day/8 Event Electronic Timer

- Chemical Resistant Materials

How The Peristaltic Metering Pump Works

- A rotating shoe passes along the length of the hose, creating a seal between the suction and discharge sides of the pump.

- As the rotor turns, the sealing pressure moves along the tube, pushing the product into the discharge line.

- When the pressure is released, the hose recovers, creating a vacuum that draws the product into the suction side.

Related Products

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.