Pulsafeeder Chemical Metering System Eliminates Chemical Spills

Eliminate Chemical Spills, Improve Safety and Increase Quality & Efficiency with a PulsaPro Chemical Metering System

The Challenge: Outdated Chemical Mixing Facility

The Customer’s chem shack in their oil refinery was aging poorly, and they needed to upgrade to solve two problems:

- Manual chemical mixing

- Level control and spill containment

Manual chemical mixing was dangerous for operators because the demulsifiers and fuel additives involved were hazardous. It was also challenging to achieve precision and consistency between batches, especially if operators were called away during the mixing process. Without operators present and level control, the mixing tanks would overflow, and chemicals would spill to the ground.

The consequences of chemical spills on the ground

Operator safety was the highest priority for the Customer. Chemical spills pose physical threats to them (slips or exposure-related injuries) and must be addressed immediately.

From a business standpoint, a chemical spill usually resulted in 1 – 1.5 days of downtime, which strained operations, wasted chemicals, impacted product quality and tied up operators and administration with internal reporting.

The Solution: Hydraulically Balanced Diaphragm Metering Pump Skids

Our Pump Application and Engineering team had multiple discussions with the Customer to solve their problems using an already approved pump vendor, Pulsafeeder.

We provided three separate hydraulically balanced diaphragm metering pump skids, utilizing Pulsafeeder’s PulsaPro API 675 compliant pumps, and worked with the Customer’s engineering team to streamline the installation. The Pulsafeeder PulsaPro pumps met the petrochemical and gas industry requirements and the specifications of the Customer’s engineering team. More importantly, the reliability and safety of a PulsaPro double-diaphragm, hydraulically actuated pump with leak detection capabilities are unmatched.

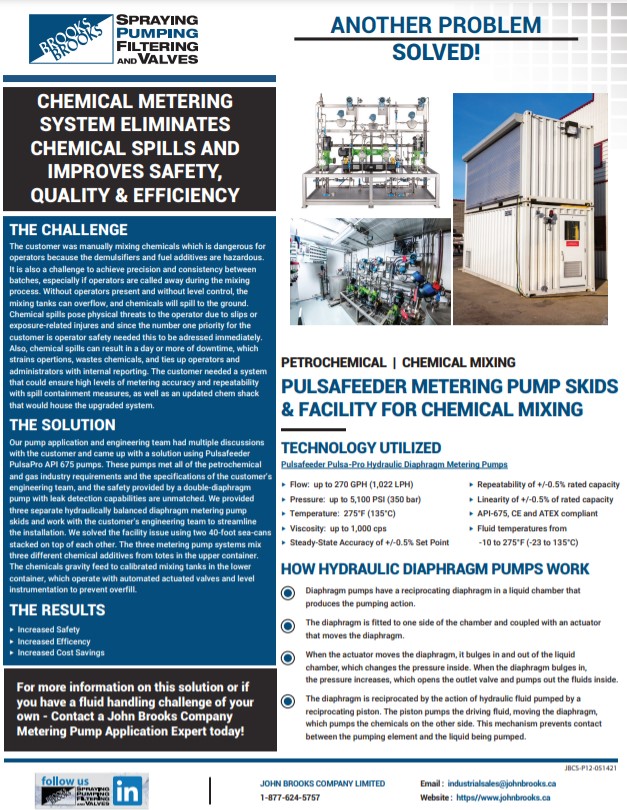

Mini challenge: The upgraded pump systems were too large for the chem shack

The existing chem shack was small, so we had to build a new mixing facility to accommodate the necessary skid upgrades. The Customer also wanted to move the shack to a new location in the plant and wanted their feed tanks nearby to prevent pump suction issues associated with long piping runs. The new space was limited, and in a Class 1 Div. 2-classified area, so we had to install transmitters and a control panel that had to be packed and purged, and we had to get creative with our building and installation.

How did we make it work?

We solved the space issue using two 40-foot sea cans stacked on each other. The three metering pump systems mix three chemical additives from totes in the upper container. The chemicals gravity feed to calibrated mixing tanks in the lower container, which operate with automated actuated valves and level instrumentation to prevent overfill.

To ensure flow accuracy, we used Coriolis flowmeters with remote transmitters on each discharge line.

The Result: Increased Quality Control and Operator Safety using Automation and Level Control

With the Pulsafeeder PulsaPro metering pump skid, we ensured significantly higher metering accuracy and repeatability levels, improving their processes and quality control from their manual batching.

With the increased automation, they were getting real-time data on their fills and batching, and their spill containment measures improved to minimize chemical exposure for operators. These improvements made their batching and mixing safer, solving their main pain point.

Since installing our solutions, the Customer has had the following:

- Zero chemical spills

- Zero operator exposure

- Improved personal and environmental safety

- Decreased batch creation time

- Increased cost savings with less chemical wastage

- Improved process uptime

Pump Technology Used

We used Pulsafeeder PulsaPro Hydraulic Diaphragm Metering Pumps to solve the Customer’s problems.

Pulsafeeder PulsaPro Hydraulic Diaphragm Metering Pump Specs

- Flow: up to 270 GPH (1,022 LPH)

- Pressure: up to 5,100 PSI (350 bar)

- Temperature: up to 275°F (135°C)

- Viscosity: up to 1,000 cps

- Steady-state accuracy of +/-0.5% of set point

- Repeatability of +/-0.5% of rated capacity

- Linearity of +/-0.5% of rated capacity

- Full-motion stroke length control mechanism

- Manual stroke length capacity control with 100:1 turndown

- Fluid temperatures from -10 to 275°F (-23 to 135°C)

- Net Positive Inlet Pressure (NPIP) required: 3 psi (0.2 bar)

- Compliant with API-675, CE and ATEX standards

- Diaphragm Types: flat, double diaphragm with pressure leak detection, HYDRAtube or HYDRAcone

- Modular configurations: simplex, duplex, triplex and multiplex up to 17 pumps

- 4-bolt tie bar

- Connection Types: NPT, BSPT, raised-face flange

- Motor Frames: 56C, 143/145TC, 182/184TC, IEC71, IEC80, IEC90

How Hydraulic Diaphragm Pumps Work

- Diaphragm pumps have a reciprocating diaphragm in a liquid chamber that produces the pumping action.

- The diaphragm is fitted to one side of the chamber and coupled with an actuator that moves the diaphragm.

- When the actuator moves the diaphragm, it bulges in and out of the liquid chamber, which changes the pressure inside. When the diaphragm bulges in, the pressure increases, which opens the outlet valve and pumps out the fluids inside.

- The diaphragm is reciprocated by the action of hydraulic fluid pumped by a reciprocating piston. The piston pumps the driving fluid, moving the diaphragm, which pumps the chemicals on the other side. This mechanism prevents contact between the pumping element and the liquid being pumped.

Related Products

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.