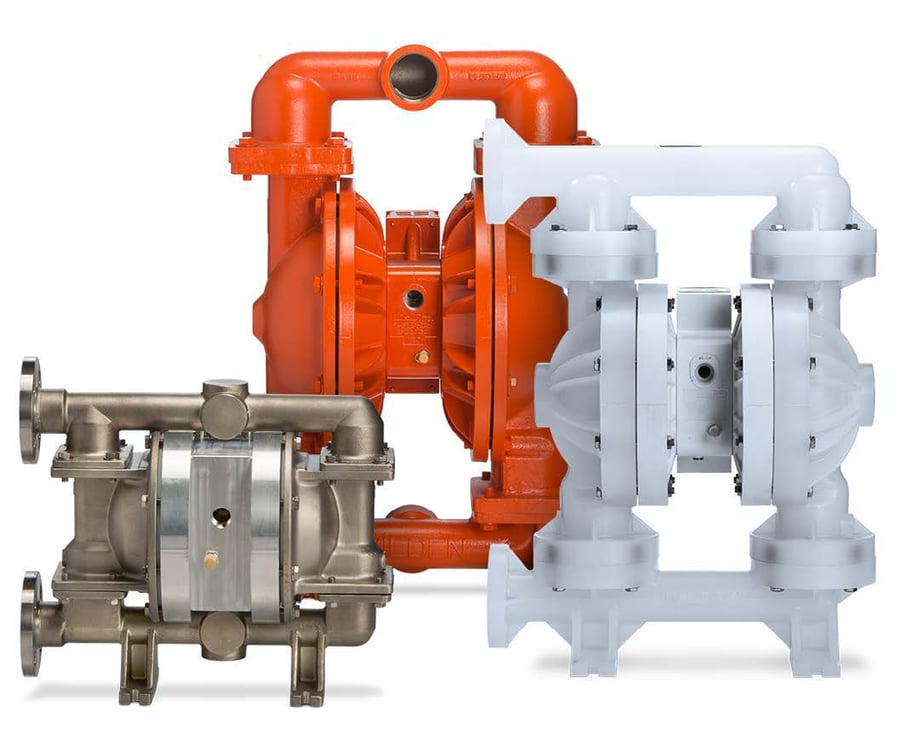

Air-Operated Double-Diaphragm (AODD) pumps service various industrial applications from hygienic to water and wastewater markets. AODD pumps are known for their unique design and reliability. These versatile pumps are a popular choice and are used in equipment of all sizes.

Working Principles of Air-Operated Doulbe-Diaphragm Pumps

Air-Operated Double-Diaphragm pumps are reciprocating positive displacement pumps that operate from energy-generated compressed air. Their design is simple. It features two diaphragms connected by a standard shaft, with two inlet and two outlet valve balls. This simple design makes them an ideal solution for many industrial liquid-handling applications.

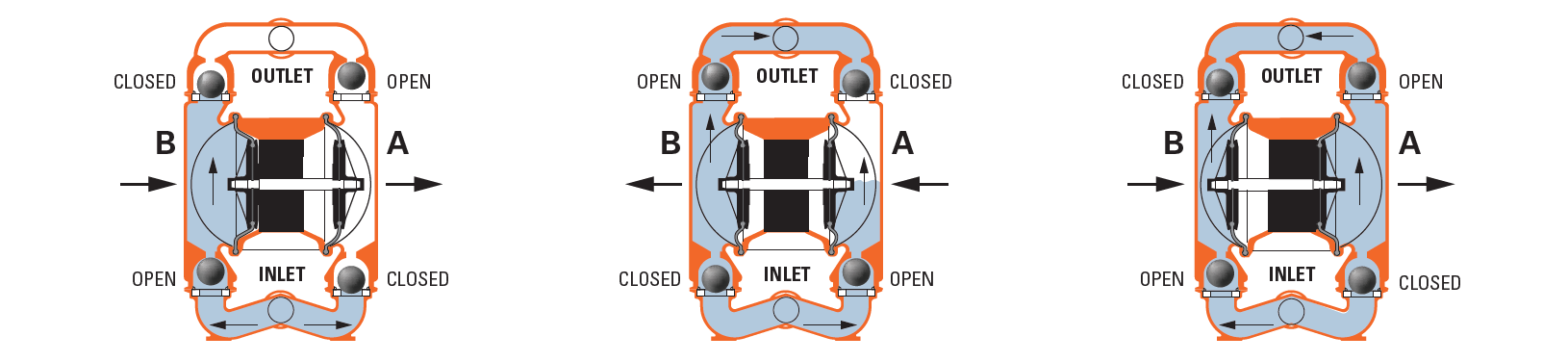

The diaphragms are powered by compressed air that moves the diaphragm back and forth, pushing the fluid through the pump. Compressed air is applied to one side of the diaphragm causing the diaphragm to flex. As a result, the liquid is forced out of the chamber on that side of the pump.

At the same time, the other diaphragm is pulled inward by the vacuum created in the opposite chamber. The compressed air is released, causing the diaphragms to return to their original position. The cycle is repeated, and fluid is moved back and forth through the pump.

The AODD pump is versatile and can handle various fluids, including abrasive and viscous liquids. It is also self-priming and can run dry without damaging the pump.

- The air valve directs pressurized air to the back side of diaphragm A.

- The compressed air moves the diaphragm away from the center of the pump.

- Diaphragm B is pulled in by the shaft connected to the pressurized diaphragm A.

- Diaphragm B is now on its suction stroke. Diaphragm B's movement toward the pump's center creates a vacuum within chamber B. It causes the atmospheric pressure to force fluid into the inlet manifold, forcing the inlet valve ball off its seat.

- When the pressurized diaphragm, diaphragm A, reaches the limit of its discharge stroke, the air valve redirects pressurized air to the back side of diaphragm B.

- The pressurized air forces diaphragm B away from the center while pulling diaphragm A to the center.

- Diaphragm B is now on its discharge stroke. Diaphragm B forces the inlet valve ball onto its seat due to the hydraulic forces.

- The hydraulic forces lift the discharge valve ball off its seat while the opposite discharge valve ball is forced onto its seat, causing the fluid to flow through the pump discharge.

- After the stroke, the air valve redirects air to the back side of diaphragm A, which starts diaphragm B on its exhaust stroke.

- As the pump reaches its original starting point, each diaphragm has gone through one exhaust and one discharge stroke. This constitutes one complete pumping cycle. The pump may take several cycles to prime entirely, depending on the conditions of the application.

Selecting the right AODD Pump

How you can decrease energy consumption with the Wilden Pro-Flo SHIFT Series AODD Pump by up to 60%

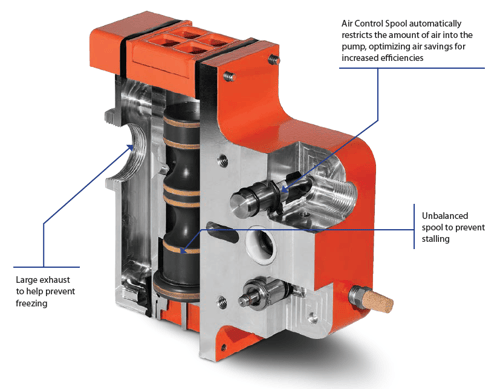

Traditionally, Air Distribution Systems (ADS) for AODD pumps have operated by filling the diaphragm cavity or air chamber with as much air as possible until the end of the stroke. This process displaces the fluid on the wetted side of the diaphragm.

A mechanical mechanism is then triggered, shutting off the air supply to that chamber. Shutting off the air supply signals the air valve to shift and dump any excess air left into the filling chamber.

This process has resulted in time delays in AODD pumps when the pressurized air is transferred from one chamber to the other and overfills the air chamber with excess air. Filling the air chambers leads to the air being vented into the atmosphere without benefiting the pumping process.

The Wilden Pro-Flo SHIFT Air Distribution System (ADS) has reduced the overall amount of compressed air required to operate the pump by optimizing the air used. The purpose of this technology is to maximize efficiency by lowering air consumption. By using the positioning-sensitive air control spool, this new technology eliminates overfilling by automatically restricting the amount of air entering the pump. This process optimizes air savings for increased efficiencies.

Wilden Pro-Flo SHIFTs automated technology results in significant air savings over conventional and advanced AODD technologies. The Wilden Pro-Flo SHIFT AODD Pump series provides up to 60% in air savings while retaining existing flow rates, reducing the total cost of ownership, ease of maintenance, and the ability to be used in harsh operating environments, and no electricity required.

When should I use an AODD Pump?

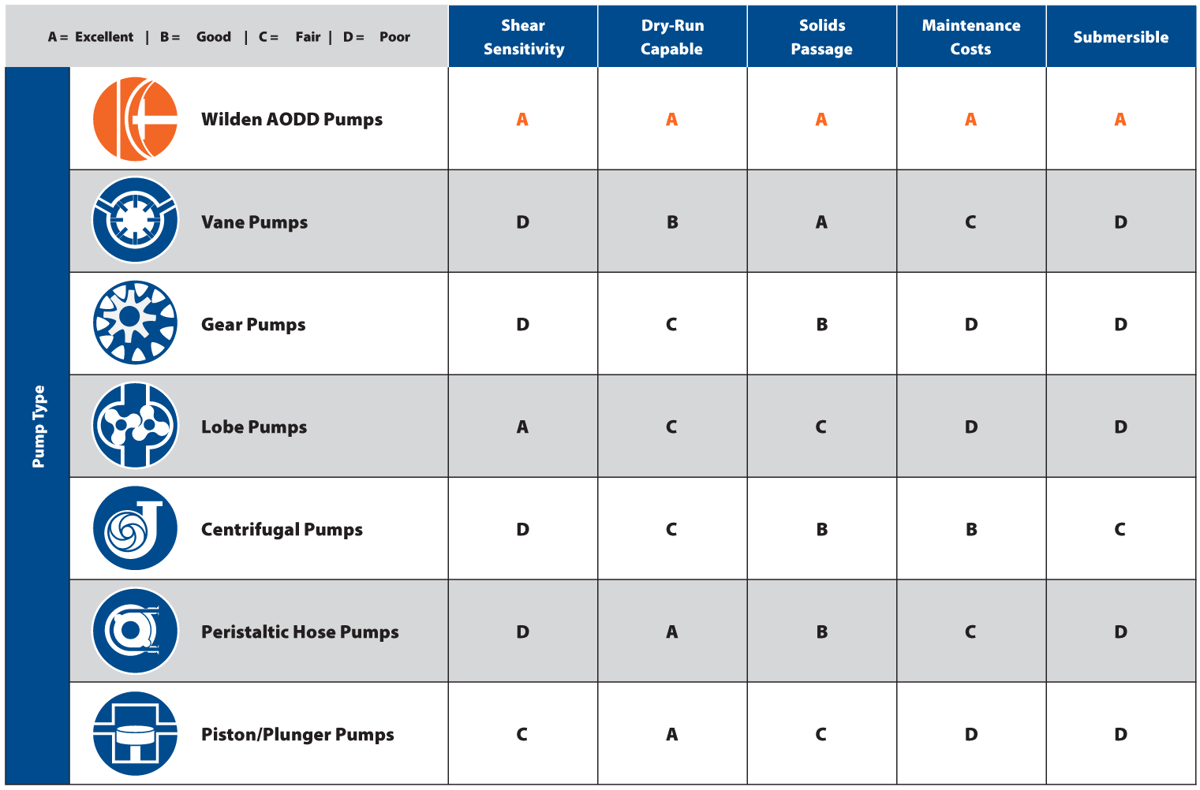

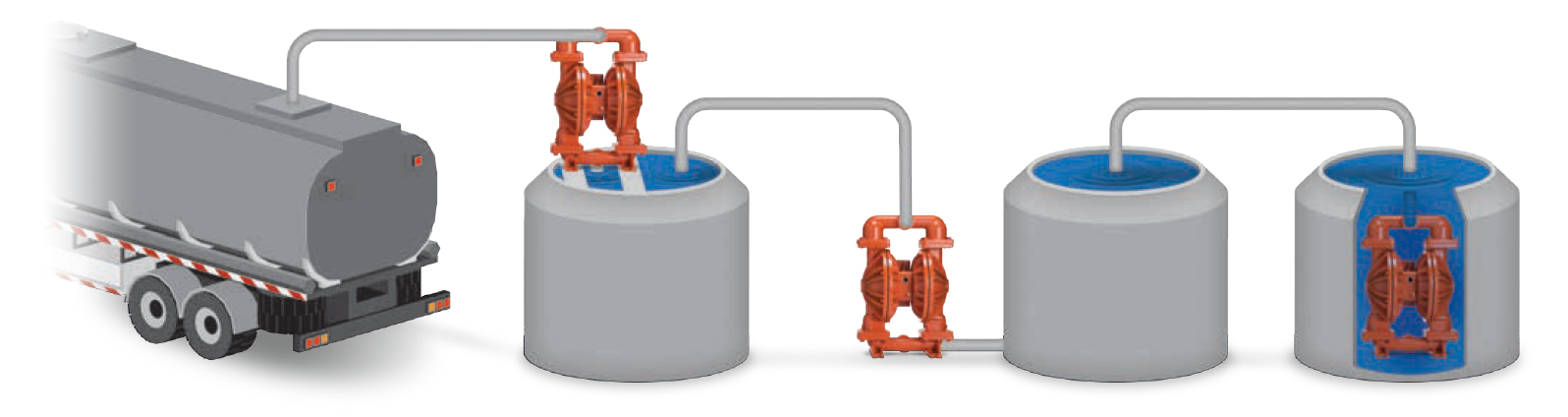

Air-operated double-diaphragm pumps provide a lot of unique benefits to all types of applications and markets.

Depending on the specific requirements, an AODD pump can be a good choice for various applications. Here are some situations where an AODD pump may be an ideal choice:

- Handling Abrasive or Viscous Fluids: AODD pumps are designed to handle abrasive and viscous fluids. These fluids may contain solids or have a high viscosity, which can be difficult for other pumps to manage.

- Chemical transfer: Often used for chemical transfer applications, AODD pumps can handle various chemicals, acids, and bases.

- Self-Priming: AODD pumps are self-priming. This means they can draw fluid from a lower level without needing external priming and start pumping without assistance.

- Run dry capabilities: They can run without damaging the pump, making them ideal for applications where dry running may occur.

- Low-pressure applications: Best suited for low to medium-pressure applications.

- Portable and easy to install: AODD pumps are lightweight and portable. They can be easily installed and moved from one spot to another, making them perfect for portable applications or installations with limited space.

An AODD pump is versatile and reliable and can handle many different fluids. This makes it an excellent choice for applications where other pump types may not be suitable.

Benefits of AODD Pumps

Thanks to their unique operating principle, AODD pumps excel in a wide variety of applications and incorporate numerous features and benefits, including:

- Self priming

- Portable

- High vacuum

- Lube-free operation

- No mechanical seals - reduces risk of leaks

- Run-dry capable

- No heat generation

- Submersible

- Superior product containment

- Easy installation

- Corrosion resistant

- Longest Mean Time Between Failure (MTBF)

- Anti-freezing

.jpeg?width=500&name=i%20(1).jpeg)