How We Reduced the Energy and Replacement Costs for Our Customer

The Challenge

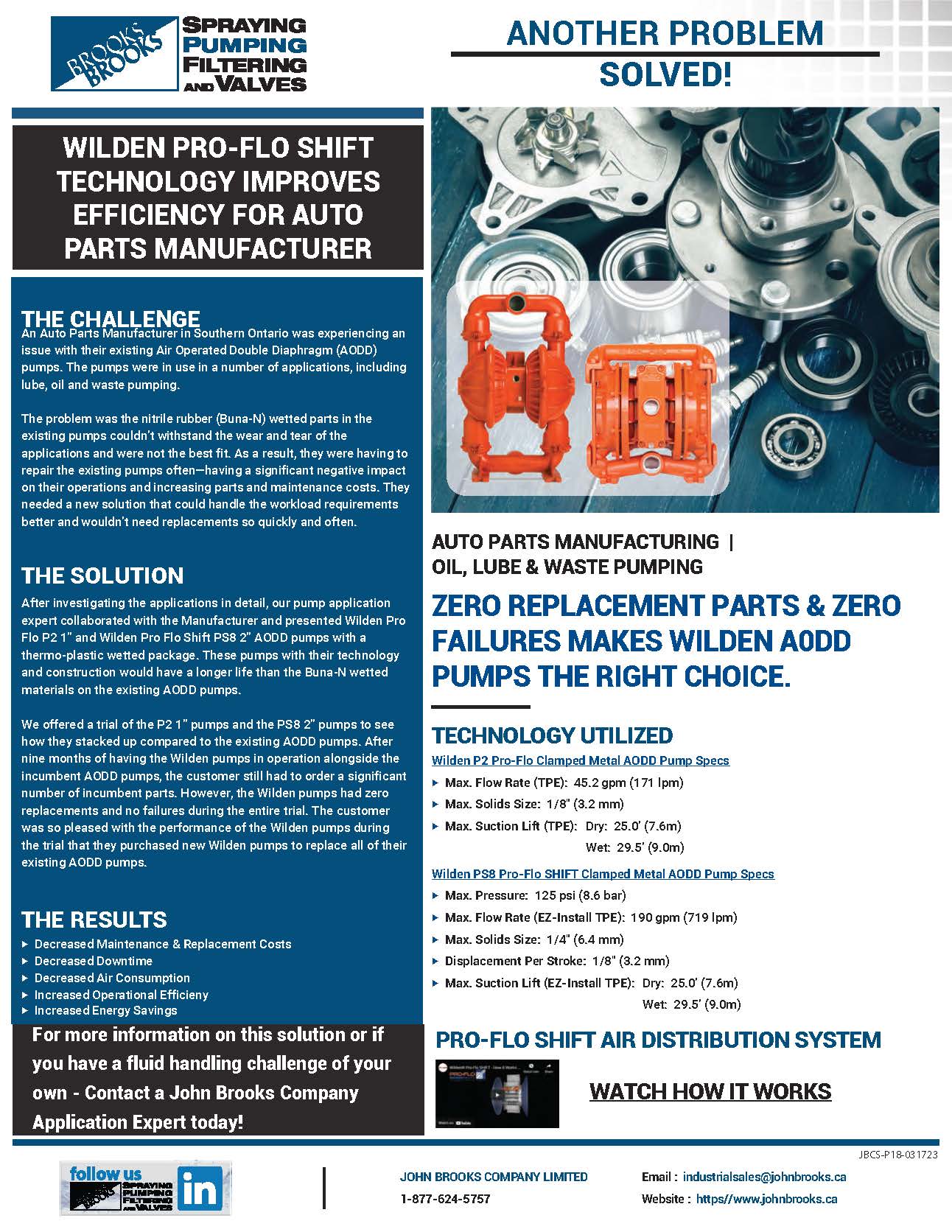

An Auto Parts Manufacturer in Southern Ontario was experiencing an issue with their existing Air Operated Double Diaphragm (AODD) pumps. The pumps were used in several applications, including lube, oil and waste pumping.

The problem was that the nitrile rubber (Buna-N) wetted parts in the existing pumps couldn’t withstand the wear and tear of the applications and were not the best fit. As a result, they had to repair the existing pumps often—significantly impacting their operations and increasing parts and maintenance costs. They needed a new solution that could handle the workload requirements better and wouldn’t need replacements so quickly and often.

The Solution

After investigating the applications in detail, our pump application expert collaborated with the Manufacturer and presented Wilden Pro Flo P2 1” and Wilden Pro Flo Shift PS8 2” AODD pumps with a thermo-plastic wetted package. With their technology and construction, these pumps would have a longer life than the Buna-N wetted materials on the existing AODD pumps. We offered a trial of the P2 1” pumps, and the PS8 2” pumps to see how they stacked up compared to the existing AODD pumps.

The advantages of the Wilden Pumps include the following:

- Wilden Pro-Flo Shift air spool automatically optimizes air consumption and eliminates overfilling of the air chambers with no reduction in flow rate.

- Wil-Flex thermoplastic diaphragms can handle abrasion and a broad swing of pH levels, and they have an inherent tensile strength that gives them a longer flex life.

- The aluminum construction material was a lighter alternative to the cast iron pumps they used previously, which eased the physical strain on the people servicing and maintaining the pumps.

- Less air is required for operation, translating to significant energy savings per month.

- Fewer components to repair, contributing to savings in replacement costs every month

- Decreased downtime due to fewer required replacements and the high Mean Time Between Repair (MTBR) of the Wilden pumps

After nine months of having the Wilden pumps in operation alongside the incumbent AODD pumps, the customer still had to order many incumbent parts. However, the Wilden pumps had zero replacements and zero failures during the trial. The customer was so pleased with the performance of the Wilden pumps during the trial that they purchased new Wilden pumps to replace all of their existing AODD pumps.

AODD Pump Technology Used

We solved the customer’s problems using Wilden Pro Flo P2 1,” and Wilden Pro Flo Shift PS8 2” pumps with Wil-Flex Elastomers EZ-Install Diaphragms.

Wilden P2 Pro-Flo Clamped Metal AODD Pump Specifications & Benefits

- Max. Flow Rate (TPE): 45.2 gpm (171 lpm)

- Max. Solids Size: 1/8″ (3.2 mm)

- Max. Suction Lift (TPE): DRY – 25.0′ (7.6m) | WET – 29.5′ (9.0m)

- NPT and BSP threaded inlet/discharge liquid connections for quick connect/disconnect

- Decades of Proven Performance

- Clamped Connections for Faster Maintenance

- Low Cost

- Simple Installation

- Ease of Operation & Maintenance

Wilden PS8 Pro-Flo SHIFT Clamped Metal AODD Pump Specs & Benefits

All the benefits of Wilden P2 Pro-Flo, PLUS

- Max. Pressure: 125 psi (8.6 bar)

- Max. Flow Rate (EZ-Install TPE): 190 gpm (719 lpm)

- Max. Solids Size: 1/4″ (6.4 mm)

- Max. Suction Lift (EZ-Install TPE): DRY – 22.73′ (6.9m) | WET – 29.5′ (9.0m)

- Displacement Per Stroke (TPE): 0.69 gal (2.6 L)

- Featuring the energy-efficient Pro-Flo® SHIFT ADS

- Greater flow

- Reduced air consumption and kilowatt usage

How Wilden AODD Pumps Work

AODD Pump Technology

Pro-Flo SHIFT Technology

An Air-Operated Double-Diaphragm pump (AODD) is a positive displacement (PD) pump. It has two flexible diaphragms that alternate filling and discharging two pumping chambers as they move. Compressed air feeds into vents from air chambers that create the pumping action on opposite sides of the filling and discharging chambers.

Because of how the pump operates, it can self-prime, deadhead, and run dry with low shear. This pump operation allows it to quickly reach and maintain the desired flow rate throughout an entire production run and withstand the abrasion of the shear-sensitive fluids.