Twin-Shaft Grinder for Sewer and WWTP

- Economical shredding of solid and disruptive matter such as wet wipes, wood, fabric, trash, and waste

- Efficient protection for pumps and system components from clogging, blockages, and damage

- Always ready for operation thanks to straightforward maintenance

- Added reliability thanks to cartridge mechanical seal technology

The Twin-Shaft Grinder that Prevents Clogging and Blockages

How the twin-shaft grinder XRipper works:

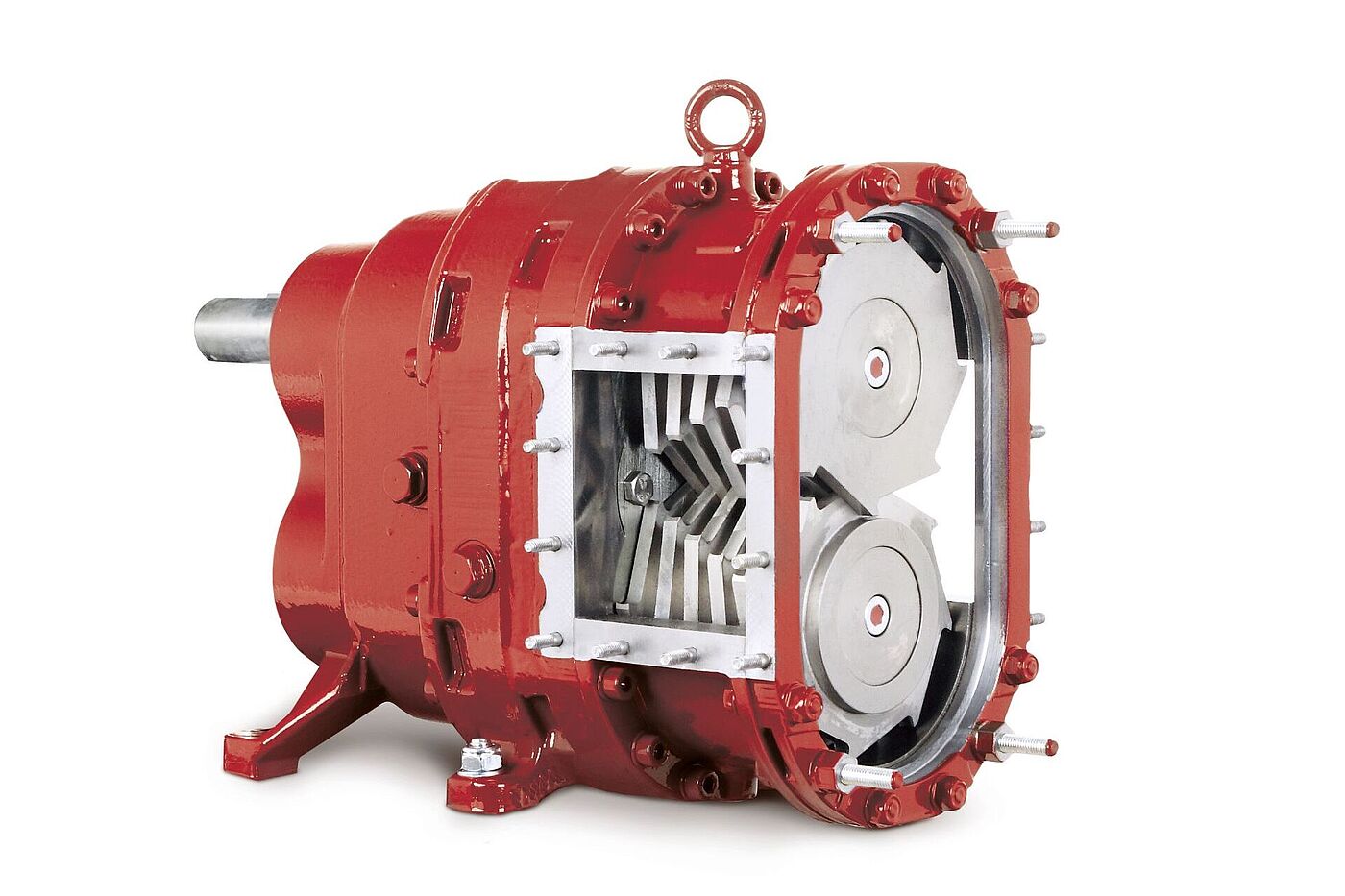

Installed directly in the fluid current, the wastewater (or other flowable medium) passes through the twin-shaft grinder XRipper virtually without hindrance. Thanks to the generously dimensioned housing, pressure loss is minimal. Solid matter and foreign matter arrive at the twin-shaft grinder XRipper along with the fluid flow, and are then guided into the central area, to the Ripper rotors. These take hold of the disruptive matter, draw it in, and shred it. In the process, solid matter is ripped, the sharp edges cut long-fibered material to pieces, and coarse and brittle components are ground up. The size-reduction ratio is adjusted by modifying the width and contour of the Ripper blades. With low speeds and high torque, the XRipper only requires low drive power to efficiently prevent clogging, blockages and damage to downstream pumps and valves.

Digitalize Your Product

Control technology for Vogelsang technology

Investing in our progressive and smart control technology significantly boosts the performance and efficiency of Vogelsang machines and systems. It captures and continuously monitors key parameters like the capacity or throughput rate, rpm, pressure and power consumption. The control detects malfunctions early, and rectifies them by intervening appropriately. The integrated communication interfaces like ProfiNet and OPC UA can exchange data with other systems or a superordinate control in real time.

At the same time, the web-based user interface displays all key data clearly in all major browsers. Optionally, the data can be accessed on mobile devices for remote monitoring.

Our experts’ experience from hundreds of applications in various areas constantly inspires our software development and lays the foundation for the major benefits for the users: low operating costs, maximum availability and efficiency.

Our range of controls offers the right solution for all machine requirements and all customers’ needs. From ready-to-use, factory-tested and commissioned system solutions for end users, to basic versions for experts who want to put the finishing touches to the control technology themselves.

The control cabinet is one of the solutions of Vogelsang control technology.

Series of The Twin-Shaft Grinder XRipper

| The economical and easy-to-maintain twin-shaft grinder | The compact inline twin-shaft grinder for pipe systems | The grinder for channels and shafts | The grinder for maximum flow rates |

|

|

|

|

| XRipper XRS | XRipper XRP | XRipper XRC-SIK | XRipper XRG |

Options in Control Technology for The XRipper

Control ModuleBasic Solution for Your Product |

| The basic set for control technology experts comprises a DIN rail-mounted control module with sophisticated, tailored software forms. As an option, it can be complemented with selected sensors that are perfectly matched to the Vogelsang machines and systems. The customer connects the wiring and sensors on-site, as well as adding any individual load circuits, safety technology and other components to create a custom control cabinet. Optionally, communication interfaces can be added in the software to satisfy the requirements of modern industrial automation, for example. |

Control CabinetReduced configuration for an easy integration |

| The Vogelsang control module installed and wired in a control cabinet. That reduces the configuration workload for control technology experts and, as a preconfigured solution, makes integration in a plant project easy. It comes with sophisticated software, tailored and high-performance drive control, safety technology and seamless integration of all relevant sensors. The customer connects the safety technology, drives (via a permanent connection) and sensors on-site using the enclosed connection diagram. On request, we can also supply sensors perfectly tailored for Vogelsang machines and systems. |

System SolutionCommissioned and tested in the factory |

| The completely pre-installed system solution offers maximum safety and convenience, especially when retrofitting machines and systems. All Vogelsang machines and additional components (e.g. fittings and sensors etc.) are installed before delivery and connected to the control. That also includes the power electronics and safety technology. The entire unit is commissioned and tested before delivery. All that is left to do on-site is to install and connect it. No programming work is required either, as the system solution is fully functional immediately. Thanks to the interplay of sophisticated software and perfectly tailored sensors, the system solution offers you the best possible performance as well as efficient, power-saving and material-friendly operation. Optionally, the system can be connected quickly and easily to the existing plant control network via ProfiNet or OPC UA, and transmit data like measurements and status information in real time. The easy-to-understand PCU user interface offers quick and simple access to all operating data, even on-the-go via tablet or smartphone. |

Features of The XRipper

Monolithic Ripper Rotors

The monolithic Ripper rotors are made of a high-quality steel block. They transfer the torque evenly from the shaft to the rotors, thereby enabling an even greater load. Service and maintenance work can be completed in a short time because far fewer individual parts need to be replaced when changing parts.

Wearing plates with counter-cutters

The axial wear plates of the XRipper are equipped with a counter-cutter that largely prevents disruptive matter from passing through the XRipper without being shredded. The result: even, reliable shredding.

Self-cleaning

As a result of the different rotational speeds of the two XRipper shafts, the XRipper rotors clean themselves. Material that has settled in the gaps between the Ripper rotors is actively raked out. This avoids clogging of rotors and any resulting reduction in flow rate.

Robust shafts and rotors

The shafts and rotors of the XRipper are dimensioned with maximum diameters. Both together make the XRipper torsionally stiff and resistant to blockage.

Rigid housing

The XRipper housing features a rigid design. This lays the foundation for the long lifetime of the bearings and gearbox.

________________________________________________________________________________________________________________________

Options of The XRipper

Ripper rotors

To adjust to the size-reduction ratio, Ripper rotors are available with blade widths ranging from 6-11 mm. They are made of hardened special steel as standard, and are also available in stainless steel for use in chemically aggressive media.

Flow-optimized housing

Flow-optimized housings are available for selection for the XRipper XRP and XRipper XRC. This means maximum throughput with the smallest possible dimensions as well as low operating and investment costs.

ATEX

An ATEX-compliant version can be supplied for use in areas subject to explosion hazards.

Materials

Depending on the series, the components of the XRipper chamber are produced from gray cast iron (XRS) or steel. Alternatively, they are available in stainless steel and/or cast stainless steel. The Ripper rotors and axial wear plates are made of highly wear-resistant special steel and are also available in a stainless steel variant.

QDS bearing

For long designs and/or if hard blockages are to be expected, the QD design gives the XRipper additional stability thanks to an additional, third support bearing – this prevents shafts from bending and the Ripper rotors from touching. Nevertheless, the QuickService functionality remains: maintenance and service are performed quickly and easily on-site.

Connector box

The connector box available for the XRipper XRS and XRipper XRP allows for heavy material, such as stones and metal parts, to be separated out upstream from the XRipper, thereby avoiding blockage of the XRipper.

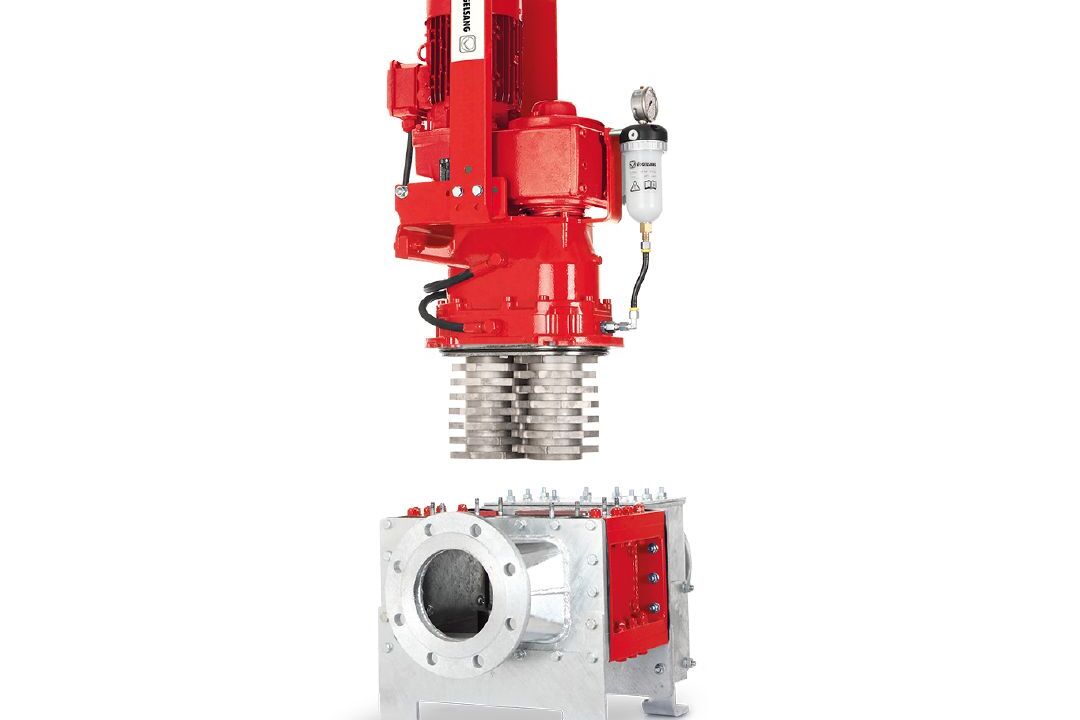

Sewer Integration Kit (SIK)

The SIK enables the XRipper XRC to be directly positioned in the channel and/or upstream of the inlet or discharge, as well as in front of slanted or rounded walls. Guide rails allow the complete XRipper to be lifted upwards and out for service and maintenance, and replaced again without an additional retaining ring.

Drive variants

A variety of different drive options are available for the XRipper. In most cases, geared motors and/or parallel shaft geared motors supply the drive power. Suitably equipped versions are available for operation in temporarily or permanently flooded conditions. Alternatively, the XRipper can be driven by a hydraulic motor.