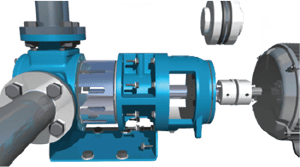

GlobalGear® Pumps tackle the toughest high-viscosity applications

Ingersoll Rand (formerly Tuthill) GlobalGear - Process Pumps are a preferred solution to support lubrication applications in large natural gas compressors.

Features:

- Strong Shaft Design – all models employ high-strength materials. This, along with oversized diameters, ensures a strong, reliable shaft with less deflection and longer seal life than our competitors.

- Built In Flush Ports - GlobalGear pumps have built in ports for easy setup of API Plan 11 or plan 13 seal flushes

- Back Pull out design - means you can remove the pump internals for repair without affecting the piping connections or alignment – This greatly reduces repair time.

- Modular Ports – GlobalGear pumps have modular ports meaning clients can choose their configuration or make changes to pumps in the field.

- High Pressure and Temperature Handling: The GlobalGear Series can handle pressures up to 525 PSI (36 bar) and temperatures up to 600°F (315°C), making it ideal for high-demand applications.

Designed for Extended Seal Life:

- Designed for Extended seal life to “Oversized Shaft & Bearing Diameters on Models GG130 – GG1200

- Large Bore Size for Stuffing Boxes

- Pressurized Fluid Paths for Seal Lubrication

- Options for Viscous Liquid Duty Seals

- In-Line Seal Maintenance

| TuffSeal™ | Heavy-Duty Slurry Seal |

|

|

Customizing your GlobalGear Pump

Ingersoll Rand (formerly Tuthill) GlobalGear Pumps are versatile and can be customized to the requirements of specific applications

Optional Features include:

- Relief Valve

- Seal Choices

- Heat Jackets

- Oversized and High Pressure Flanges

- Abrasive Fluid Special Construction

- High Temperature Construction

- Modular Port Options

Back Pull-Out Design Greatly Reduces Service Down-Time

Piping can be repaired with disturbing piping or shaft alignment.

API 676 Packages

Ingersoll Rand designs GlobalGear® pump packages to satisfy a growing customer base of large, international Oil & Gas end users with API 676 standard requirements (with some exceptions). This standard is set forth by the American Petroleum Institute to establish guideline specifications for the use of rotary positive displacement pumps in petroleum, petrochemical, and gas industry services.

Ingersoll Rand can offer API 682 mechanical seals for API 676 configured pumps and allowable nozzle loads that are two times or more greater than the minimum allowable nozzle loads specified in API 676. Tuthill also offers the complete package of baseplate, electric motor, gear reducer, coupling, and guard that addresses API 676 features and specifications, along with other project specific requirements.