What Are Self-Priming Pumps?

Self-priming pumps are liquid pumps designed to have liquid already inside the pump body to start the priming process. They’re used to increase operational efficiencies because the start-up liquid is already inside the pump, making it primed and ready to pump.

Self-priming pumps are found most often in process plants and are used for various repeated, intermittent functions.

However, they are also the pump of choice for many industrial applications, including:

- Waste management and sewage-handling,

- Steel and paper mills,

- Mining operations,

- Food processing,

- Automotive factories,

- Wineries, and more.

Self-Priming Centrifugal Pumps vs. Standard Centrifugal Pumps

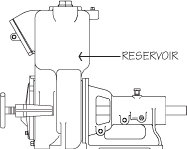

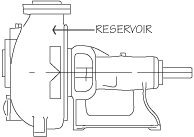

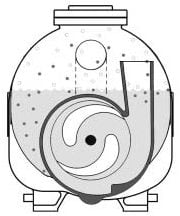

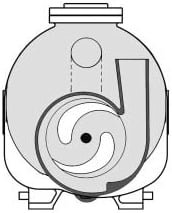

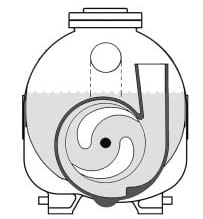

Self-priming centrifugal pumps are different from standard centrifugal pumps because they have a liquid reservoir built into the unit. The built-in reservoir, sometimes called the separation chamber, enables the pump to discharge air from the casing and the suction line by recirculating liquid during the priming cycle.

| The reservoir may be above the impeller | or in front of the impeller. |

|---|---|

|

|

What Are the Advantages of Self-Priming Centrifugal Pumps?

Self-priming centrifugal pumps:

- Can handle a variety of liquids including, slurries, corrosive liquids, and suspended solids.

- Require very little attention, resulting in significant savings of maintenance time and money and making them a sensible solution for industrial and municipal applications.

- Are easy to install and service.

- Easily manage frequent and intermittent pumping operations.

What Are the Disadvantages of Self-Priming Centrifugal Pumps?

Some disadvantages include:

- They cannot operate without the initial priming liquid in the pump’s reservoir.

- They are typically larger than standard models because of the need for the liquid reservoir—sometimes this limits their applications if space is limited.

- The pumps need to be as close as possible to the liquid source to reduce the amount of empty suction line and, therefore, the amount of air needed to evacuate.

How to Prime a Self-Priming Pump

There are essentially nine steps for a self-priming pump to work, which we detail below. You can also see them in action in the Self-Priming Basics video from Gorman-Rupp.

The 8 Steps to Priming a Self-Priming Pump

Centrifugal self-priming pumps have two phases or cycles to operate: the priming cycle and the pumping cycle.

| PRIMING | PUMPING | AT REST |

|---|---|---|

|

|

|

- During the priming cycle, the rotating impeller creates a vacuum at the impeller’s eye that draws compressed air from the suction line into the pump.

- Differential pressure pushes the air up the suction line, and a ring of liquid forms inside the pump casing around the impeller, creating an air-tight seal. The seal prevents air in the discharge line from leaking back into the suction line.

- Air bubbles trapped in the liquid within the impeller’s vanes move up towards the discharge chamber where the liquid and air bubbles separate.

- Under gravity’s effect, the heavy liquid flows back down through a recirculation port to the pump reservoir, and the air evacuates through the open-ended discharge line or an air-release device.

- As the liquid recirculates through the pump casing and the air evacuates, we create a low-pressure system at the impeller’s eye. Due to a differential in pressure, higher atmospheric pressure outside the pump forces liquid up the suction line.

- Differential pressure continues to push the liquid up the suction line, pushing the air ahead of it into the impeller where it evacuates through the recirculation process until the liquid from the suction line reaches the pump chamber.

- Complete pumping operation (the pumping cycle) begins at this point, stopping the recirculation process so the pump can discharge the liquid.

- After the pump completes its job, it’s shut off. When it’s off, the prime chamber retains enough liquid so it can self-prime again for future use.

What Causes a Pump to Lose Its Prime?

A failure to prime is one of the most common issues technicians and maintenance workers have to troubleshoot. Although there are plenty of reasons why a pump loses its prime, it’s most commonly caused by air leaks, air binding, face clearance issues, or clogging.

- Air leaks. As you know, liquid must recirculate inside the pump casing to create the low-pressure vacuum that draws liquid up the suction line into the pump. If there’s an air leak, the pressure differential inside the pump can’t drop below the atmospheric pressure outside, making it impossible for the suction line to pull a vacuum.

- Air binding. During priming, air is handled through the recirculation process and evacuated off the discharge side. Air binding occurs when air is not vented to the atmosphere and collects on the discharge side. The now pressurized discharge side stalls the priming process until the air is vented.

- Face clearance. The higher the clearance (or the more space) between the wear plate and the impeller, the weaker the vacuum created by the pump. If the vacuum isn’t strong enough to lower the internal pressure of the pump, atmospheric pressure can’t force liquid up the suction line. This clearance issue is often caused by general wear on the plate or impeller.

- Plugged impeller eye. If debris clogs up the impeller’s eye, you’ll lose all the impeller’s hydraulic capability and priming will never complete.

- Poor recirculation. If debris plugs up the recirculation port, the pump won’t properly recirculate liquid within the casing, resulting in a failure to prime.

You can see these five issues in action in Gorman-Rupp’s Failure to Prime video.

How to Choose the Right Self-Priming Pump for Your Application

Choosing the right pump isn’t always easy, which it’s important to lean on the experts. In the Selection & Application brochure from Gorman-Rupp, you’ll learn some of the things you’ll need to know before settling on the right pump for the job.

Some things you should know include:

- How to calculate the Total Dynamic Head (TDH) of a centrifugal pump

- How to calculate the Net Positive Suction Head (NPSH) of a self-priming pump

- How to use a performance curve to select a pump

- How to select the correct motor for your pump

Want to get started? Download the Guide or Contact Our Experts for a free consultation.