SEEPEX CS – FOOD PUMPS

SEEPEX CS food pumps are used in areas with sensitive hygienic requirements and cleanliness is a critical factor. SEEPEX food and hygienic pumps fulfill even the strictest hygiene requirements in the food, pharmaceutical, cosmetics and chemical industries, conveying both high- and low-viscosity substances with minimal shear effect. They ensure product quality at all times in compliance with 3-A Sanitary Standards. The components of our food and hygienic pumps are designed in compliance with EHEDG principles. The BCFH range even has certification to mark it as particularly hygienic and easy to clean. All materials in contact with the pumping product naturally fulfill the international requirements of the FDA and EU 1935-2004.

Features and Benefits:

- High product safety: stator material and secondary seals are FDA approved (Food and Drug Administration, USA)

- CIP (Clean In Place) with high velocity flow in the suction casing

- US 3-A Sanitary Standards and EHEDG compliance

- Particularly easy to maintain due to easy-to-assemble joints along with the plug-in connection between the rotating unit and drive

- No special tools needed for assembly/disassembly

- Optimized, dead-space-free pump casing prevents product build-up

- High-quality casing surfaces and the rotating internal parts ensure residue-free cleaning

- Multiple mechanical seal options ensure hygienic shaft sealing

- SIP (Sterilization In Place) with superheated steam

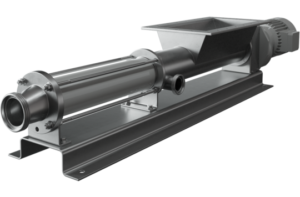

SEEPEX BTCS – HOPPER PUMP IN HYGIENIC DESIGN

FOOD AND HYGIENIC PUMP WITH HOPPER

The design of the BTCS food and hygienic pump from SEEPEX is characterized by a rectangular hopper with a compression zone and feed screw conveyor. This makes it particularly suited for pumping highly viscous, minimally flowable products – both with and without solids. In the hygienic design, the pump is fitted with open joints. However, it is optionally available with closed pin joints.

Features and Benefits:

- Available with a choice of open hygienic joints or closed pin joints, suitable to your individual application

- Certified under the 3-A Sanitary Standards (variant with open joints) and designed in compliance with the EHEDG guidelines, and fitted with FDA-approved and EU 1935-2004 compliant components

- Conveying capacity: 0.03 – 130 m³/h (0.132 USGPM – 572 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Special housing geometry and open, hygienic pin joints facilitate optimal cleaning and sterilization: CIP, SIP, COP

- Optimal filling of conveying chambers through feed screw and conically closing compression zone

- Hermetically sealed elastomer sleeves are particularly suited for abrasive pumping media

- Minimal pulsation and low shear characteristics allow the gentle conveyance of sensitive media

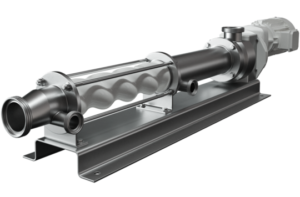

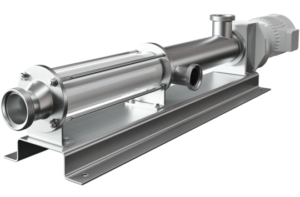

SEEPEX BCF – FLEXROD DESIGN

FOOD & HYGIENIC PUMP WITH JOINT-FREE, FLEXIBLE TITANIUM SHAFT

The BCF food and hygienic pump from SEEPEX, with its joint-free, flexible titanium shaft (Flexrod) is certified under 3-A Sanitary Standards. Tangentially positioned flush connections allow residue-free cleaning in CIP and SIP processes. Optimal cleaning and sterilization can also be achieved when disassembled (COP). Thanks to minimal pulsation and shear characteristics, it is particularly suitable for conveying of sensitive food.

Features and Benefits:

- Highest hygienic standards along with corrosion and wear resistance

- Conveying capacity: 0.09 – 60 m³/h (0.4 – 264 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Certified US 3-A Sanitary Standards, fulfills EHEDG requirements, utilizes FDA approved components

- Residue Free Cleaning with special housing geometry, joint-free Flexrod and tangentially positioned flush connections: CIP, SIP, COP

- US 3-A Sanitary Standards and EHEDG compliance

- Low cleaning costs and reduced production facility downtime due to quick and simple maintenance

- Minimal pulsation and low shear characteristics allow the transport of sensitive products – even containing whole pieces

- Low space requirements and no special tools required for maintenance – simply release the Flexrod from the rotor and drive shaft

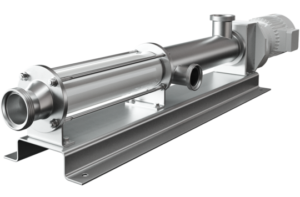

SEEPEX BCFH – FLEXROD DESIGN – EHEDG CERTIFICATION

|

|

CERTIFIED FOOD & HYGIENIC PUMPS

Where hygiene is of critical importance, the BCFH food and hygienic pump from SEEPEX safeguards particularly hygienic processes. The EHEDG Type EL Class I certificate verifies optimal cleaning and sterilization results, which are facilitated by the joint-free Flexrod design, a split suction casing with CFD-optimized geometry, and tangentially positioned flush connections. Thanks to minimal pulsation and shear characteristics, the BCFH food and hygienic pump it is particularly suitable for conveying of sensitive food.

Features and Benefits:

- Awarded the EHEDG Type EL Class I certification and certified according to 3-A Sanitary Standards, FDA-approved components

- Conveying capacity: 0.09 – 60 m³/h (0.4 – 264 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Residue Free Cleaning with CFD optimized housing geometry, joint-free Flexrod and tangentially positioned flush connections: CIP, SIP, COP

- Low cleaning costs and reduced production facility downtime due to quick and simple maintenance

- Minimal pulsation and low shear characteristics allow the transport of sensitive products – even containing whole pieces

- Quick and simple maintenance without dismantling the suction line thanks to split suction casing – simple release of the Flexrod from the rotor and drive shaft

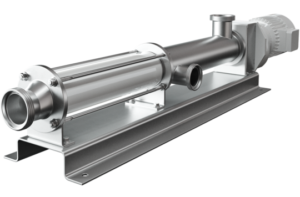

SEEPEX BCSO – OPEN PIN JOINTS

FOOD & HYGIENIC PUMP WITH OPEN PIN JOINTS

The hygiene-compliant design of the BCSO food and hygienic pump from SEEPEX is certified under 3-A Sanitary Standards. It can be cleaned without leaving any residues using CIP and SIP methods, and therefore fulfills the strictest requirements for hygienic cleanliness. Furthermore, the materials of the individual components are food-certified (FDA / EU 1935-2004). Thanks to the special design of the corrosion and wear-resistant joints, maintenance work can be performed quickly and without special tools.

Features and Benefits:

- Certified under the 3-A Sanitary Standards and designed in compliance with the EHEDG guidelines, and fitted with FDA-approved and EU 1935-2004 compliant components

- Conveying capacity: 0.03 – 130 m³/h (0.132 – 572 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Residue Free Cleaning with special housing geometry and open, hygienic pin joints facilitate optimal cleaning and sterilization: CIP, SIP, COP

- Open, aseptic pin joint enables higher pressure and conveying capacities

- Low cleaning costs and reduced production facility downtime due to quick and simple maintenance

- Minimal pulsation and low shear characteristics allow the transport of sensitive products – even containing whole pieces

- Service-Friendly Maintenance without the need for special tools thanks to the open design of the joints, using only a few components

SEEPEX BCSB – CLOSED PIN JOINTS

FOOD & HYGIENIC PUMP WITH OPEN PIN JOINTS – APPLICATION VERSATILITY

SEEPEX BCSB food pump from fulfills the requirements of many applications in the food, cosmetics and chemical industries. The materials of the individual components are food-certified (FDA / EU 1935-2004). The joints, which are hermetically sealed by elastomer sleeves and therefore particularly wear-resistant, ensure a long service life. It can be cleaned using CIP, SIP and COP methods for optimal hygiene.

Features and Benefits:

- Economical Food grade pump with FDA-approved and EU 1935-2004 compliant components

- Conveying capacity: 0.03 – 130 m³/h (0.132 – 572 USGPM)

- Pressure: ≤ 24 bar (350 PSI)

- Sophisticated design for excellent cleaning results: CIP, SIP, COP

- Wear Resistant – Joints hermetically sealed with elastomer sleeves

- Minimal pulsation and low shear characteristics allow the gentle conveyance of sensitive media

- Low space requirements; standard components facilitate simple maintenance

John Brooks Company is a proud supplier of SEEPEX pumps in Canada. Our application experts work from coast to coast and can find the best solution for you, whether you’re looking for a food grade pump, a progressive cavity pump, minor or substantial system upgrades – the list goes on. Request a quotation today, and one of our application experts will get back to you as soon as possible.