HEAT-LES DESICCANT COMPRESSED AIR DRYERS

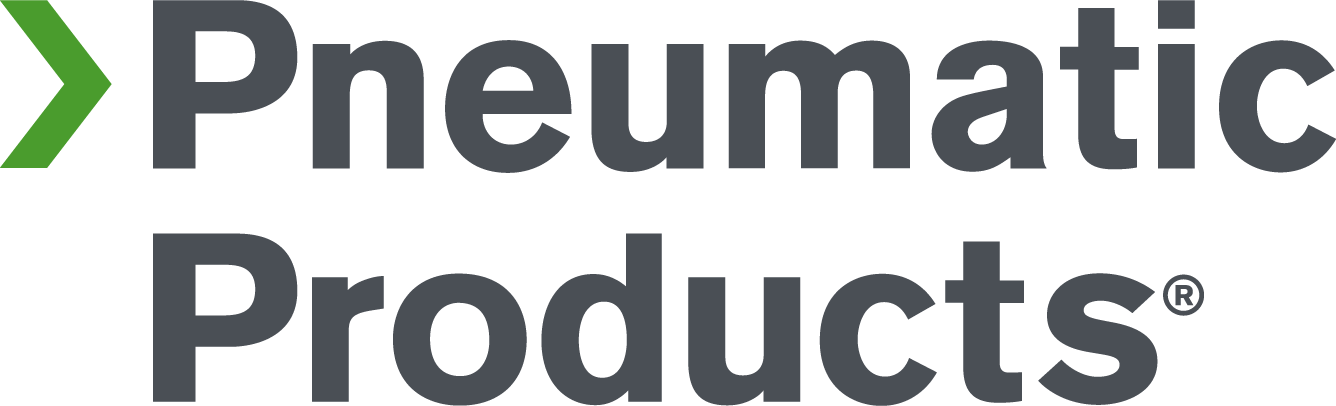

Pre-configured dryer packages range from a basic fixed-cycle unit to a high pressure, corrosion-resistant model. Every unit we build incorporates our AMLOC® energy management system to assure long component life cycles and maximum energy savings.

DHA/CDA-EM1 Configuration

The DHA/CDA-EM1 dryer has been designed with the following upgraded features that are commonly requested in demanding applications:

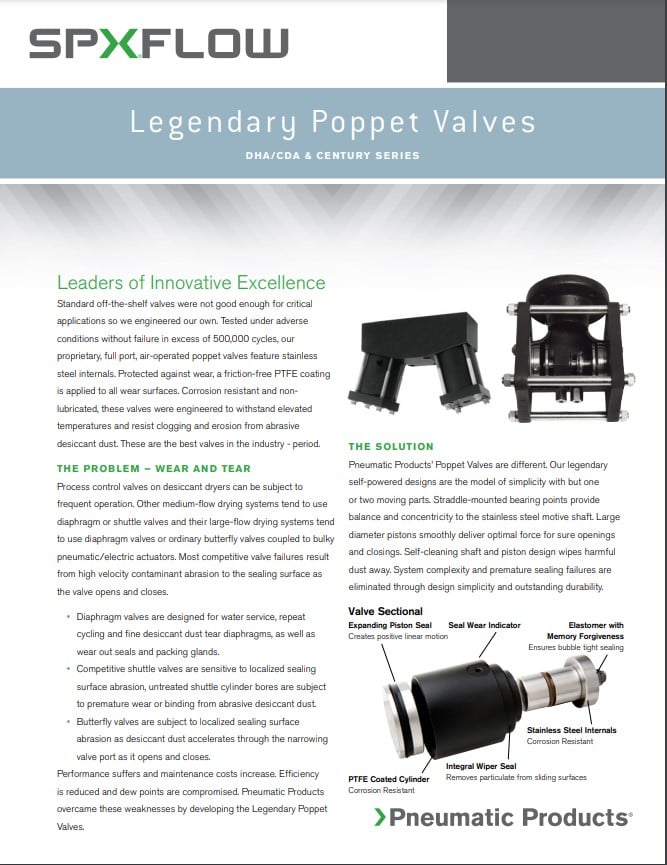

- Legendary Select Series or Century Series control valves feature stainless steel internal parts designed specifically for desiccant dryer service and tested to 1,000,000 cycles, bubble-tight

- Welded manifold construction to eliminate leaks

- ASME coded vessels-full penetration welds (with backing rings), 1/16″ corrosion allowance and two-part epoxy finish

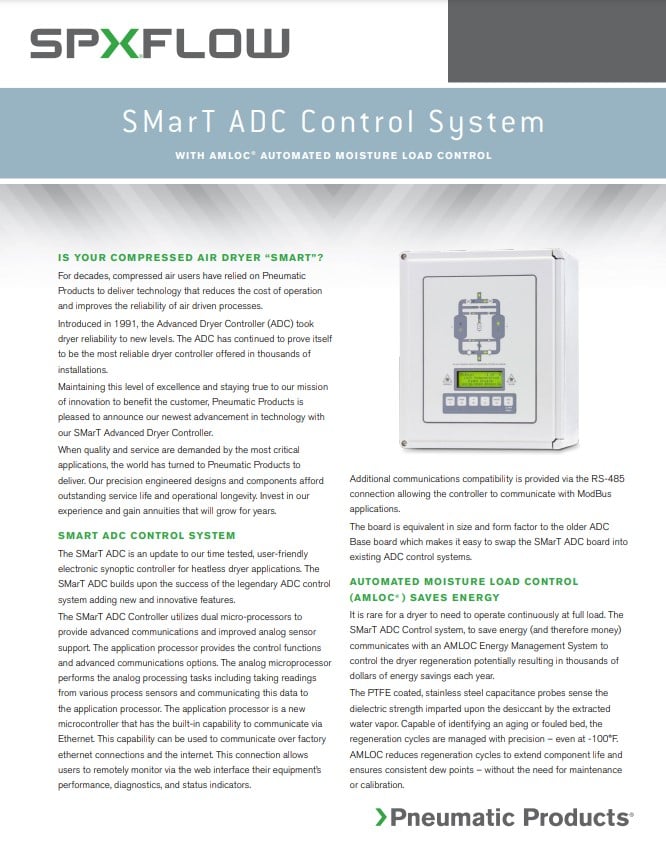

- Modular Electronic Controller (MEC) with AMLOC® energy management

- Aquadex ® moisture indicator

- Pre-mounted prefilter and afterfilter (other mounting options available: duplex, block and bypass valves)

- Heavy-duty low-noise exhaust muffler

- High Humidity Alarm

DHA/CDA-PM Configuration

The DHA/CDA-PM dryer is further upgraded with our Advanced Diagnostic Controller (ADC) with AMLOC® energy management, panel mounted Aquadex and inlet/outlet pressure gauges. Additional modifications made available to this model include:

- Stainless steel or copper instrument air tubing

- SS Aquadex moisture indicator

- SS relief valves

- SS inlet/outlet pressure gauges

DHA/CDA-PMX Configuration

The DHA/CDA-PMX dryer is our top-of-the-line configuration designed for the most demanding applications. It features the following standard components:

- Legendary Select Series or Century Series control valves feature stainless steel internal parts designed specifically for desiccant dryer service and tested to 1,000,000 cycles, bubble-tight

- Flanged manifold construction with removable stainless steel inlet and outlet diffuser screens

- ASME coded vessels-full penetration welds (no backing ring), 1/8″ corrosion allowance, two-part epoxy finish with shot-blast preparation.

- Modular Electronic Controller (MEC) with AMLOC® energy management (upgradeable to ADC or pneumatic controls)

- Stainless steel air tubing and instrument package

- Pre-mounted PPC prefilter and afterfilter with stainless steel housings

- Heavy-duty low-noise muffler

- SS Aquadex moisture indicator