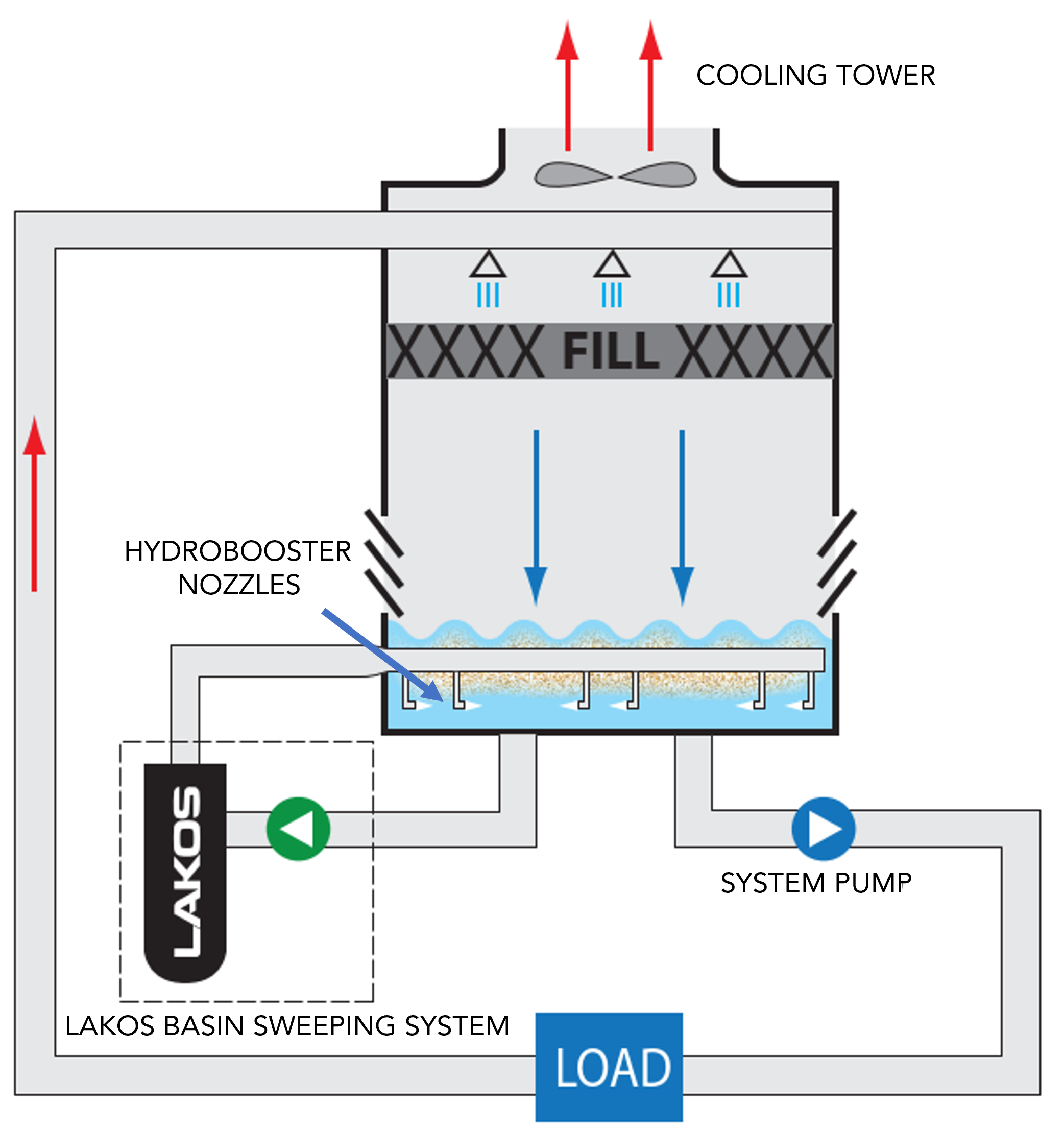

Cooling Towers and the Need for Filtration

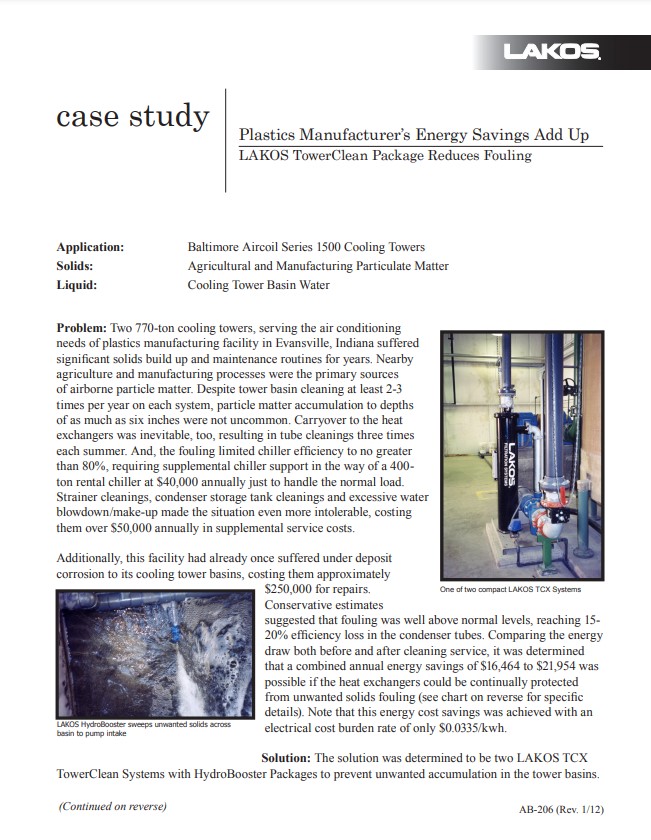

Cooling tower filtration plays a crucial role in lowering a system’s water temperature and maintaining long-term system performance. These systems act as the workhorse of water-cooled operations, pulling in outside air and evaporating water to reduce temperatures — while also scrubbing airborne contaminants. This is accomplished by bringing outside air and water inside the tower, where some water is evaporated, reducing the temperature of the residual water recirculated inside the system. A secondary function of a cooling tower is acting as an air scrubber cleaning the air brought inside the tower typically containing airborne contaminants. Airborne contaminants dust, sand, and pollen are scrubbed from the air and mixed in with the towers water supply. These contaminants get trapped inside towers water flow and cause under-deposit corrosion, biological growth, scale, fouling, and decrease overall system efficiency.

Problems Created in Cooling Towers

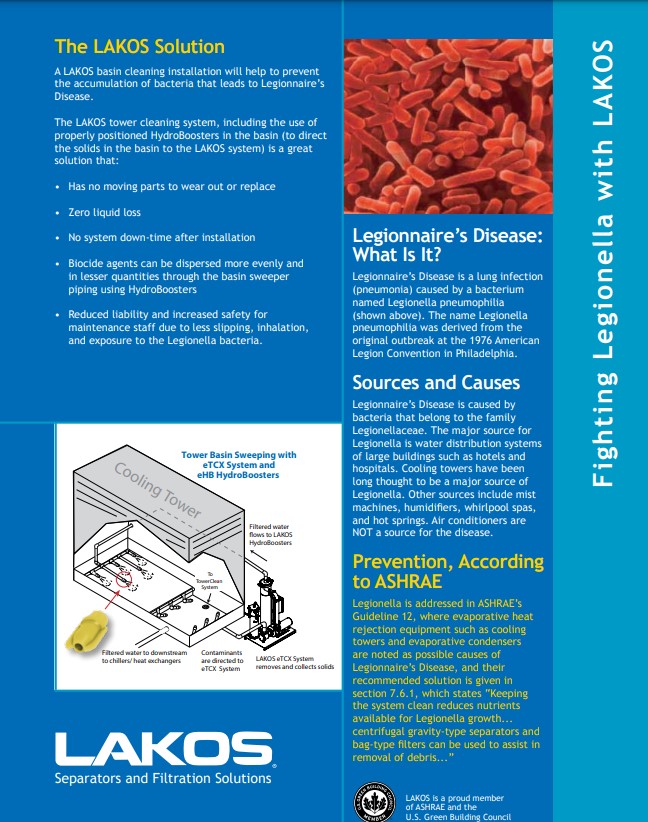

| Biological Growth |

| Evaporative coolers and cooling towers offer a warm, moist environment for biological activity to thrive and multiply creating a biofilm. Biological activity contributes to increased fouling of heat transfer surfaces (including tower fill) leading to corrosion of various parts of the cooling system and can create health hazards such as legionella. |

| Corrosion |

| In a cooling towers basin, less than 1/16” (1.58mm) of solids accumulation interferes with the effectiveness of water treatment with respect to under-deposit corrosion. In this vicious cycle, solids congregate allowing sulphate reducing bacteria (SRB) to multiply unchecked. The SRB’s reduce sulphate’s in the water to hydrogen sulfide resulting in aggressive pitting corrosion, commonly known as under-deposit corrosion that decreases equipment life by as much as 75%. |

| Scale |

| Scale is characterized by the plating-out of Calcium Carbonate (CaCO3) on heat transfer surfaces. These deposits are created through precipitation of dissolved minerals from cooling tower water. As CaCO3 mixes with silica and water it forms a hard, concrete scale on heat transfer surfaces reducing a system’s ability to efficiently transfer heat. The formation of scale is the most common reason for the need to punch and clean chiller tubes. |

Solids Removal in Cooling Tower Systems

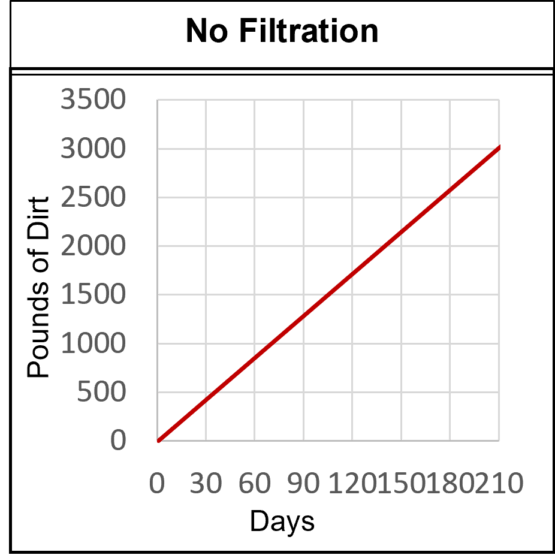

| No Filtration |

| Solids continually accumulate in tower basins and heat transfer efficiency is greatly impacted. |

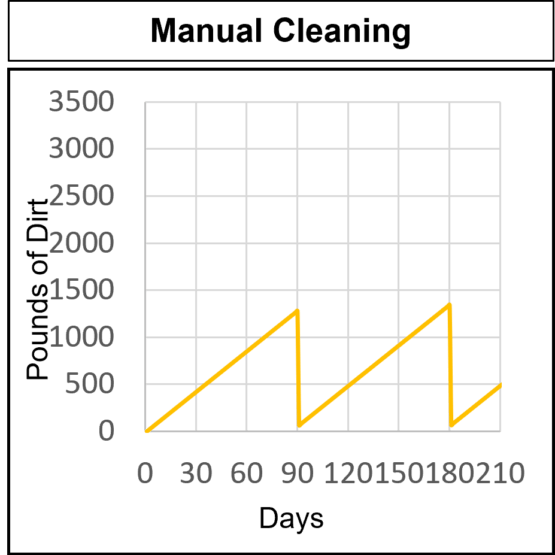

| Manual Cleaning |

| Labor intensive removal of solids that never addresses the underlying problem. |

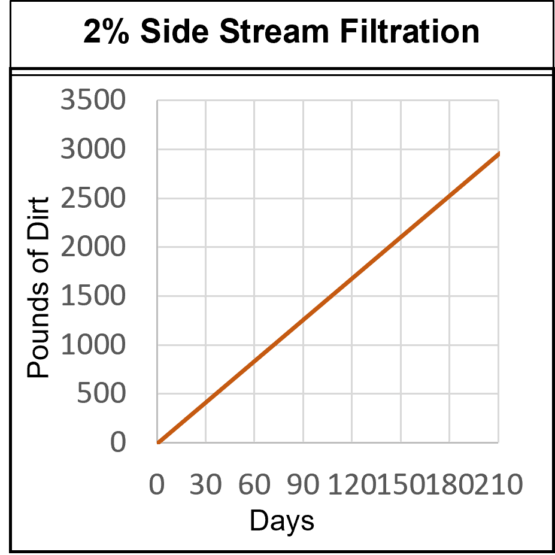

| 2% Side Stream |

| Removes a portion of solids; solids still accumulate in the basin where the bulk of material settles. |

| Basin Cleaning |

| Attacks problem at the source by directing and removing solids directly from the basin. |

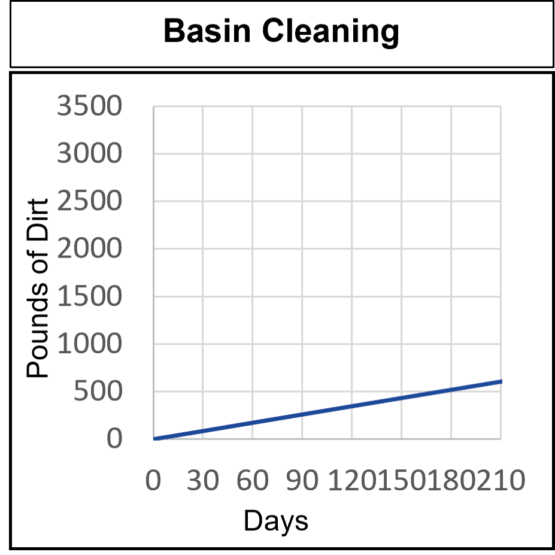

Why Continuously Remove with LAKOS

ASHRAE states that “A typical 200-ton cooling tower operating 1,000 hours may assimilate upwards of 600 lbs. of particulate matter from airborne dust and the makeup water supply.” (ASHRAE Handbook, 2020 Ch 40.16) This is an important metric when considering the number of solids that accumulate and hinder your own HVAC system.

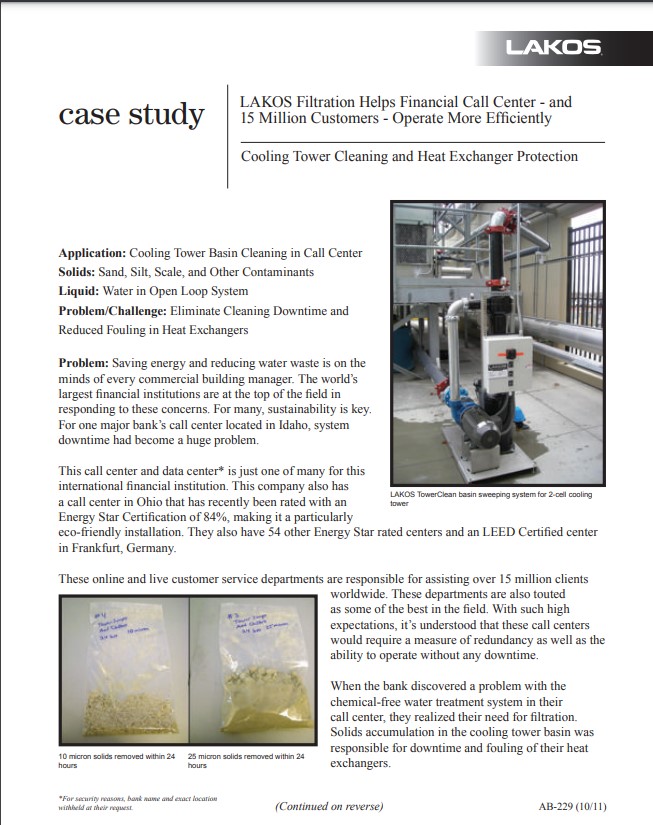

At a recent install site of a LAKOS Basin Sweeping System a 15-year veteran operator was astonished by the improvements the LAKOS System had on their equipment. The basin had recently undergone a deep cleaning with the LAKOS System installed a few weeks after the cleaning. On startup, the basin sweepers stirred up and agitated all the sediment that collected since the deep cleaning, with the operator equating it to, “…a muddy river after a heavy rain.” After a weekend of operation with the LAKOS System, the operator could not believe how clean the water was. Stating that, “It looked better than it did when I filled it with fresh water after the deep cleaning.”

There are many advantages to adding LAKOS Filtration to your HVAC System. You can expect to reduce system maintenance, extend equipment life, maintain thermal design efficiencies, and retain valuable liquid and chemicals in your system.

Benefits for Cooling Tower Water Filtration

- Reduce under-deposit corrosion, remove food source for biological activity, and extend life of the basin

- Minimize manual cleaning, maintenance, downtime and risk of injury

- Maintain downstream thermal efficiency of heat transfer surfaces

-

HydroBoosters™ sweep cooling tower basin to remove suspended solids at the source

Basin Cleaning Videos

How To Keep cooling Tower Basins Clean

Benefits of Using LAKOS Cooling Tower Basin Cleaning

Save Your Customer time & Money with Cooling Tower Filtration