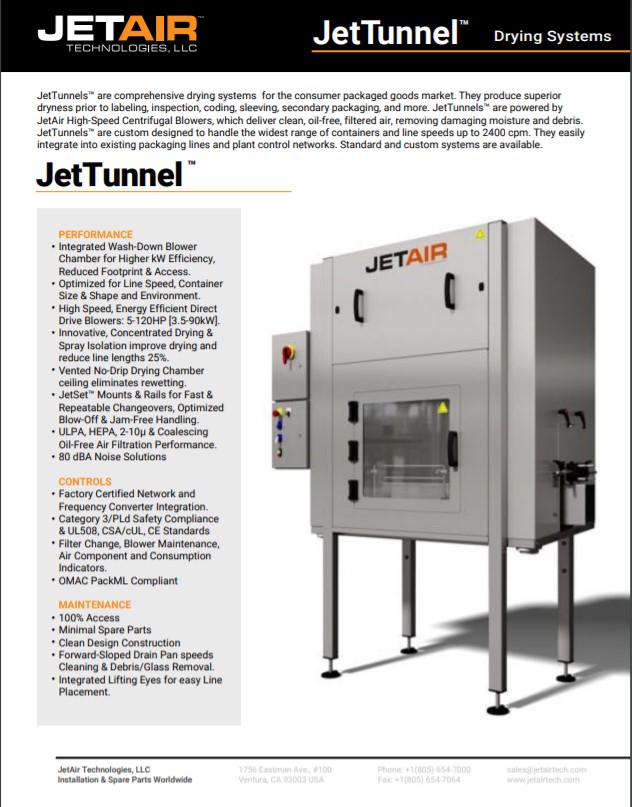

JetTunnel Air Knife System for Superior Drying

The JetAir JetTunnel™ Air Knife System is a comprehensive drying system for the consumer packaged goods market. These systems produce superior dryness prior to labeling, inspection, coding, sleeving, secondary packaging, and more. The JetTunnel™ Drying System is powered by JetAir High-Speed Centrifugal Blowers, which deliver clean, oil-free, filtered air, removing damaging moisture and debris. JetTunnel™ Air Knife Systems are custom designed to handle the widest range of containers and line speeds up to 2400 cpm. They easily integrate into existing packaging lines and plant control networks. Standard and custom systems are available.

PERFORMANCE

- Integrated Wash-Down Blower

- Chamber for Higher kW Efficiency, Reduced Footprint & Access

- Optimized for Line Speed, Container Size & Shape and Environment

- High Speed, Energy Efficient Direct Drive Blowers: 5-120HP [3.5-90kW]

- Innovative, Concentrated Drying & Spray Isolation improve drying and reduce line lengths 25%

- Vented No-Drip Drying Chamber ceiling eliminates rewetting

- JetSet™ Mounts & Rails for Fast & Repeatable Changeovers, Optimized Blow-Off & Jam-Free Handling

- ULPA, HEPA, 2-10μ & Coalescing Oil-Free Air Filtration Performance

- 80 dBA Noise Solutions

CONTROLS

- Factory Certified Network and Frequency Converter Integration

- Category 3/PLd Safety Compliance & UL508, CSA/cUL, CE Standards

Filter Change, Blower Maintenance, Air Component and Consumption Indicators - OMAC PackML Compliant

MAINTENANCE

- 100% Access

- Minimal Spare Parts

- Clean Design Construction

- Forward-Sloped Drain Pan speeds Cleaning & Debris/Glass Removal

- Integrated Lifting Eyes for easy Line Placement

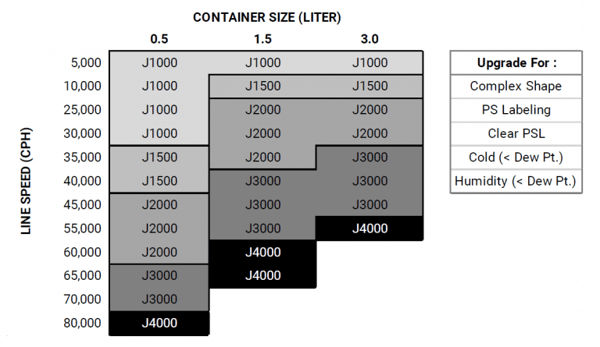

PERFORMANCE SPECIFICATIONS

ENGINEERED TO ORDER:

- Inspection, Coding, Steam Tunnel, Labeling, Sleeving Integrations.

- Heated/Cooled Air Solutions

- Corrosive Material Handling

- OEM plc “Tab” Development

- Clean-Wetness Sensing & Control

- Sanitary & Clean Room Solutions

- Customized Solutions

- Turbine Development

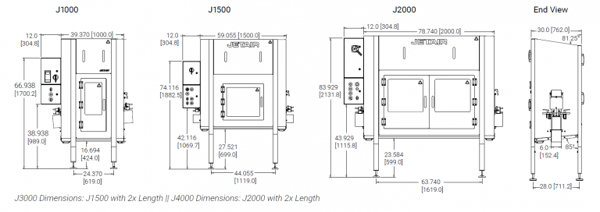

DIMENSIONS & PART NUMBERS

TECHNICAL SPECIFICATIONS

Construction:

- Washdown Stainless Steel 304 – [SS316 & CPVC Solutions Available]

- Electrical Panel NEMA4/IP66

- 100% Access from Front or Backside

- Integrated Lifting Eyes (4)

- Overspray Drainage & Capture 2”FPT

- Clean Design

Voltage:

- 190-240VAC, 380-480VAC, 600VAC

- 50/60Hz, 3 Phase

Power:

- 2HP[1.5kW]-120HP[90kW]

Air Source: JetAir High-Efficiency DirectDrive Blower

- Belt-Free, No Pinch Point, No Tensioner

- Ø4”[100] Outlet

Configurations:

- 1-4 M Lengths

- 750-1250mm Widths

- TOC 20”[500]-48“[1220]

- Corner Solution & TOC >48”[1220] Available

Safety Features:

- UL508, cUL, CE Standards

- CAT 3-4/PLd-e Available

- Sound Attenuation

Sound:

- 78-85dB

Standard Options:

- Table-Top & Side-Grip Conveyors

- Container Dynamic Hold-Downs

- Container Twist Integration

- Liquid Rinse & Recycle Integration

- Auto Chamber Cleaning (CIP-R)

- Dehumidification

- Ion De-Static

- Vacuum Integration