JET-2G Centrifugal Blower – Single Stage –

- Flow: 1350 cfm [2300M 3Hr]

- Pressure: 95″ WG [240m Bar]

- Vacuum: 85″ WG [210m Bar]

The JET-2G™ is ideal for air knife drying, vacuum, fluidized bed, cooling and exhaust applications. The JET-2G™ features belt-free DirectDrive™ Technology (US & Int’l. Pat. Pend.), which is enabled by a proprietary high-speed motor and an aerodynamically designed blower. DirectDrive™ enhances reliability and boosts performance by eliminating belts, tensioning devices and complex spindle assemblies common in other high-speed blowers. The JET-1™ is engineered for moderate flow and moderate pressure applications from 10HP [7.5 kW] to 20HP [15 kW]. Its design and compact footprint enable it to fit into the widest range of OEM equipment.

Advantages of the JET-2G Centrifugal Blower:

Efficient Power:

- The JET-2G™ is 10 – 12% More Efficient than Belt Drive Units

- Available in 10-20 HP or [7.5-15 kW] Ratings.

- Flow: 1350 cfm [2300M 3Hr]

- Pressure: 95″ WG [240m Bar]

- Vacuum: 85″ WG [210m Bar]

Ultra Compact:

- Smallest Footprint

- One-Man Install

- Fed-Ex, DHL, and UPS Delivery Available

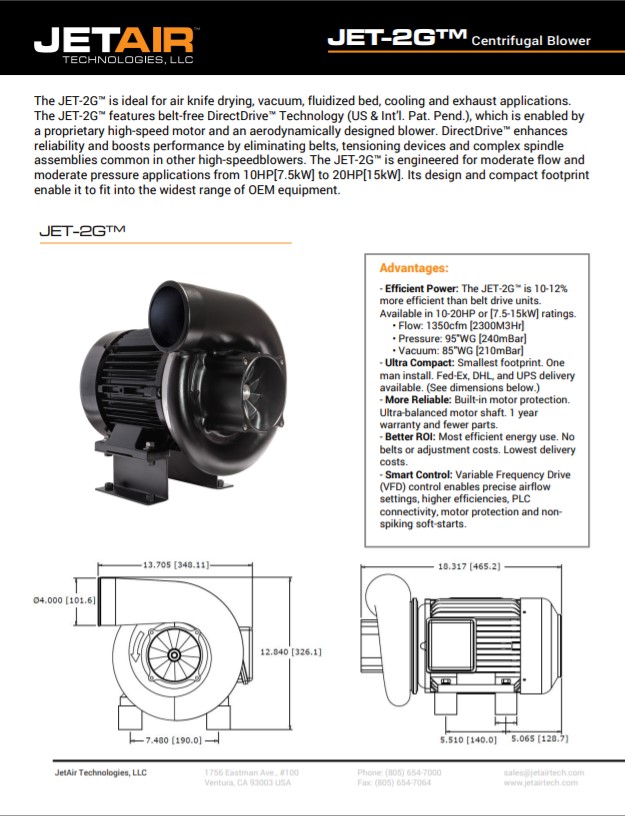

Dimensions:

- Width: 13.70″[348mm]

- Length: 18.32″ [465mm]

- Height: 12.84″ [326mm]

More Reliable:

- Built-in Motor Protection

- Ultra-Balanced Motor Shaft

- Fewer Parts

- 1 year Warranty

Better ROI:

- Most Efficient Energy Use

- No Belts or Adjustment Costs

- Lowest Delivery Costs

Smart Control:

- Variable Frequency Drive (VFD) Control Enables:

- Precise Airflow Settings

- Higher Efficiencies

- PLC Connectivity,

- Motor Protection

- Non-Spiking Soft-Starts.

Technical Specifications of the JET-2G Centrifugal Blower:

Description:

- DirectDrive™ Technology

- Single Stage Centrifugal Compressor

- Oil-Less, Spindle Free Design

Drive System:

- DirectDrive™ Technology with Variable Frequency Drive Control

- Integrated Motor Protection

- Air Cooled Rated: 105ºF [40ºC]

Impeller

- 5 Axis C355 Aluminium

Aero-Blower:

- A356-T6 Aluminum with Integrated Lifting Eye

High-Speed Motor:

- TEFC

- IP54

- External Junction Box

- 10-20HP [7.5 – 15kW]

- 3-Phase, 190-220, 390-480 and 600VAC,

- 50/60Hz

- Thermister

- 105ºF [40ºC] Ambient

Weight:

- 79lbs.[36kg]

Connections:

- Inlet 5ӯ [126mm]

- Outlet 4ӯ [102mm]

- 360º Rotation

Warranty:

- 1 Year.

Applications for the JET-2G Centrifugal Blower include:

Beverage

- Dry for Labeling, Coding, Inspection & Secondary Packaging

- Single File or Mass Flow

- Clean Containers using Ionized Air before Filling

Food

- Dry for Labeling, Coding & Secondary Packaging

- Smooth & Cure Coatings

- Remove Loose Product

- Remove Excess Water

- Dry Conveyors

- Move Product

Pharmaceuticals

- Dry Pouches – Gusseted, Pillow, etc.

- Air Rinse and/or Dry Containers with HEPA-Filtered Air

- Remove Debris

- Dry IV Bags

Industrial

- Machine Tool Coolant Removal

- Dry Sheets, Crates, Wire, etc.

- Dry Large Applications

- Debris, Bead Blast & Casting Sand Removal

- Dry before Coding

- Cooling

Powder

- Dry Powder Blenders of any Size

- Remove Statically Charged Powder from Container Interiors & Exteriors

Automotive

- Battery Process Drying, Pre-Paint Ionized Air Rinse, Parts Blow-Off

Textiles

- Vacuum Cutting Tables

Customized Solutions

- Engineered-to-Order Systems for any of your drying and air rinsing applications.

JetAir Technologies’ technical staff designs systems that are easy to use, install, and integrate into existing lines. Their drying and blow-off systems are equipped with best-in-class safety features found only in JetAir Systems. Drying and Blow-Off solutions are available in multiple configurations, performances and control schemes.

Call a Specialist today 1-877-624-5757