Hydro-Thermal SilverLine Smart Cooking Systems – Steam Innovation in your Kitchen

Hydro-Thermal SilverLine cooking systems where steam becomes an ingredient – Sterilized water is directly infused into the food as it courses through the heart of the SilverLine, the Infuze™ cooker. Here, steam becomes an ingredient, gently and efficiently cooking the food, bringing it to target temperature. This allows 100% of the steam’s energy to transfer to the food. Kettles and heat exchangers only offer 80% – 85% energy transfer. What could you do with an annual savings of 20% on your energy bill?

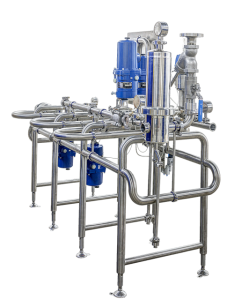

Steam has been used to safely process foods and beverages for more than half of a century. Hydro-Thermal has 80 years of steam expertise and the SilverLine is our latest innovation. The SilverLine is a streamlined, self-contained, polished stainless steel system designed to cook recipes exactly as specified, replacing heat exchangers and kettles. Our patented food and beverage processing system mixes steam and liquid foods and beverages completely while delivering precise and consistent temperature control, instantaneous heating and no scaling or fouling of the product.

What your food tastes like is not only a reflection of what ingredients you use and their quality; it reveals direct evidence of how it was treated during the cooking process. We realize that equipment imparts a signature on your food, so the SilverLine™ is a critical ingredient in your recipe.

Hydro-Thermal SilverLine Cooking Systems Set a New Industry Standard

A new standard has been set for food and beverage processing systems with the SilverLine. It exceeds expectations in every way imaginable and provides direction for the future.

The SilverLine is a streamlined, self-contained, polished stainless steel system designed to replicate processing profiles exactly as specified. Its simple design and appearance are deceptive. This one device encompasses thousands of hours of engineering boiled down into one superior, dynamic machine. It has been touted as the most advanced food and beverage processing system on the planet and has been revered by respected leaders in the commercial food and beverage industries.

Bryn Craggs, food scientist, owner of Beech Royd Consultancy and 30 year veteran of the commercial food industry remarked, “The most meaningful benefit of the SilverLine is the increase in productivity that it provides. You can cook food with less equipment, time, maintenance and floor space.”

The SilverLine also delivers extremely consistent quality in every run. Imagine having meticulously predictable results in a cooking system that drives up productivity and shreds maintenance costs up to 50%. Imagine a system so well designed that it defines a new benchmark for internal and external hygiene. The SilverLine continuously processes food and beverages more efficiently, consistently and hygienically than any other solution on the market.

Hydro-Thermal Silverline Applications

What foods does the SilverLine usually cook?

The common factors that unite all of the foods that the SilverLine cooks is that they must be in a liquid state and have water as an ingredient. The system is particularly well suited for…

- Soups

- Sauces

- Meat Pastes

- Vegetable Purees,

- Cheese Sauces

- Milk or Cream-based Products

The SilverLine is not suitable for confections, nougat, chocolate and caramel, as these require the removal of water.

Don’t see the food you produce listed here? As a company with 80 years of steam innovation, we are always looking to expand our cooking possibilities.

What beverages are usually processed with the SilverLine?

The SilverLine is well suited for processing many different types of fruit juice blends, juices with particulates, high Brix sugar water, sports drinks containing whey and milk based drinks. It is also an excellent choice for extracting teas, coffees and other extractives. The SilverLine’s extensive versatility allows it to easily heat beverages well over boiling (100◦C), which positions it as a very effective pasteurization system.

What particle size can go through the system?

The maximum allowable particle size depends on both the type of particle and the size of the SilverLine system. Here are some examples of particle size paired with the correct SilverLine system configuration:

Model: 1.5”

- Max Non-Bridging Particle: 0.51″

- Max Bridging Particle: 0.25″

Model: 3”

- Max Non-Bridging Particle: 0.64”

- Max Bridging Particle: 0.32”

Is the SilverLine a pasteurization system?

Yes. The SilverLine has the ability to control both steam and product pressures, allowing heating well above 100 degrees Celsius. Additionally, the SilverLine contains all of the data logging and controls necessary to meet UHT pasteurization requirements. It can also accommodate multiple holding tube sections of customer specified length to meet the needs of nearly an infinite number of foods and beverages.

Products

Is the SilverLine 3A certified?

Yes. The SilverLine, as a complete system, exceeds 3A requirements and is listed on certificate number 811. The Infuze™ cooker is also listed on the same certificate. The design of the SilverLine far exceeds 3A requirements, with its complete CIP bypass to allow complete cleaning of the steam header, and Infuze cooker internals to ensure maximum hygiene.

Where does it fit into my commercial kitchen?

The SilverLine has a very small footprint. The single cooker model is only 1.2m wide by 2m long. Additional cookers can be added to the system, increasing its length by only 0.6m. At 1.5m tall, the system can be fitted under walkways and platforms, in small areas next to walls or in the floor space where your old kettle was located. This is 1/3 to 1/2 the size of a 4000L kettle. Say yes to cooking efficiency with efficient design.

Is the SilverLine the right choice for my company?

Yes. The SilverLine is versatile enough to replace a kettle, yet cooks continuously like a heat exchanger. It has a small footprint, extremely low maintenance, eliminates burn on and is easy to clean in place. It was designed to reduce air consumption, use small amounts of power and reduces steam energy consumption by 15-20%. Does that sound like the right choice for your company?