Hydra-Cell Seal-less Pumps. Positive Displacement Pumps with a seal-less pumping chamber so there are no seals, packing or cups to leak or replace. The seal-less design and check valves enable Hydra-Cell to handle abrasives and particulates that would damage other types of pumps. In addition, Hydra-Cell Seal-less Pumps can run dry indefinitely without damage to the pump.

The multiple-diaphragm design of Hydra-Cell provides virtually pulse-less, linear flow without the need for expensive pulsation dampeners.

|

|

|

|---|---|---|

| D10 Pump Series – Learn More | D35 Pump Series – Learn More | H25 Pump Series – Learn More |

|

Max Flow: 8.8 gpm Metallic Pump Heads Non-Metallic Pump Heads |

Max Flow: 36.5 gpm Metallic Pump Heads |

Max Flow: 20 gpm Metallic Pump Heads Non-Metallic Pump Heads |

|

||

| M03 Pump Series – Learn More | ||

|

Max Flow: 3.1 gpm Metallic Pump Heads Non-Metallic Pump Heads |

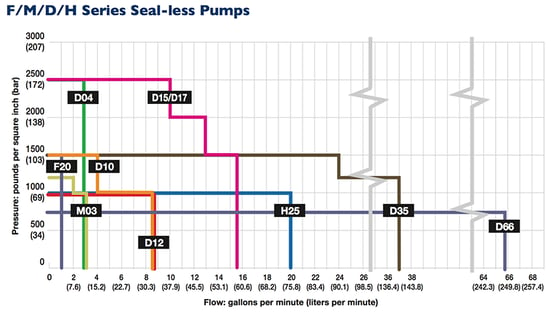

The graph above displays the maximum flow capacity at a given pressure for each model series. The table below lists the maximum flow capacity and maximum pressure capability of each model series.

Please Note: Some models do not achieve maximum flow at maximum pressure. Refer to the individual model specifications in this section for precise flow and pressure capabilities by specific pump configuration.

| Model | Maximum Capacity gpm (l/min) |

Maximum Discharge Pressure psi (bar) |

Maximum Operating Temperature ºF (ºC)** |

Maximum Inlet Pressure psi (bar) |

||

|---|---|---|---|---|---|---|

| Non-Metallic* | Metallic | Non-Metallic | Metallic | |||

| M03 | 3.1 (11.7) | 350 (24) | 1200 (83) | 140º (60º) | 250º (121º) | 250 (17) |

| D10 | 8.8 (33.4) | 350 (24) | 1500 (103) | 140º (60º) | 250º (121º) | 250 (17) |

| H25 | 20.0 (75.9) | 350 (24) | 1000 (69) | 140º (60º) | 250º (121º) | 250 (17) |

| D35 | 36.5 (138) | N/A | 1500 (103) | N/A | 250º (121º) | 500 (34) |

** Consult factory for correct component selection for temperatures from 160 ̊F (71 ̊C) to 250 ̊F (121 ̊C).

|

|

|

|---|---|---|

| T100 Pump Series – Low Pressure | T100 Pump Series – Medium Pressure | T100 Pump Series – High Pressure |

| Max Flow: 96 gpm

Metallic Pump Heads |

Max Flow: 45 gpm

Metallic Pump Heads |

Max Flow: 26 gpm

Metallic Pump Heads |

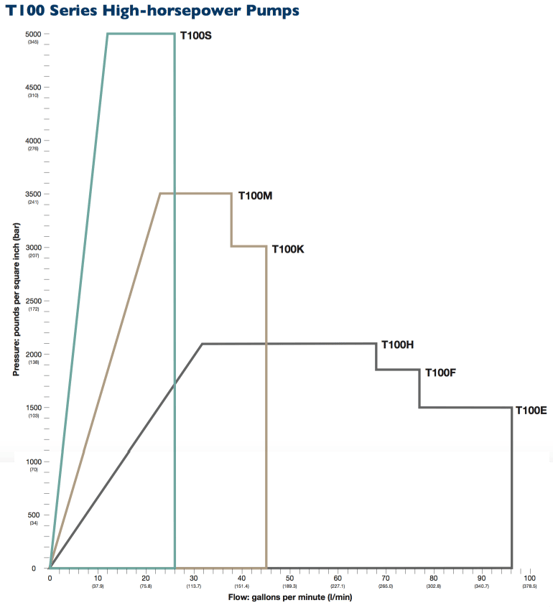

The graph above displays the maximum flow capacity at a given pressure for each model series. The table below lists the maximum flow capacity and maximum pressure capability of each model series.

Please Note: Some models do not achieve maximum flow at maximum pressure. Refer to the individual model specifications in this section for precise flow and pressure capabilities by specific pump configuration.

| Maximum Capacity gpm (l/min) |

Maximum Discharge Pressure psi (bar) |

Maximum Inlet Pressure psi (bar) |

Maximum Operating Temperature * F (C) |

|

|---|---|---|---|---|

| T100E | 96.0 (366.1) | 1500 (103) | 500 (34) | 180 ̊ (82 ̊ ) |

| T100F | 76.5 (289.6) | 1850 (128) | 500 (34) | 180 ̊ (82 ̊ ) |

| T100H | 68.0 (257.8) | 2100 (145) | 500 (34) | 180 ̊ (82 ̊ ) |

| T100K | 45.0 (170.4) | 3000 (207) | 500 (34) | 180 ̊ (82 ̊ ) |

| T100M | 38.0 (143.8) | 3500 (241) | 500 (34) | 180 ̊ (82 ̊ ) |

| T100S | 26.0 (98.4) | 5000 (345) | 500 (34) | 180 ̊ (82 ̊ ) |

* Consult factory for correct component selection for temperatures above 180 ̊ F (82 ̊ C) or below 40 ̊ F (4 ̊ C)

|

|

|---|---|

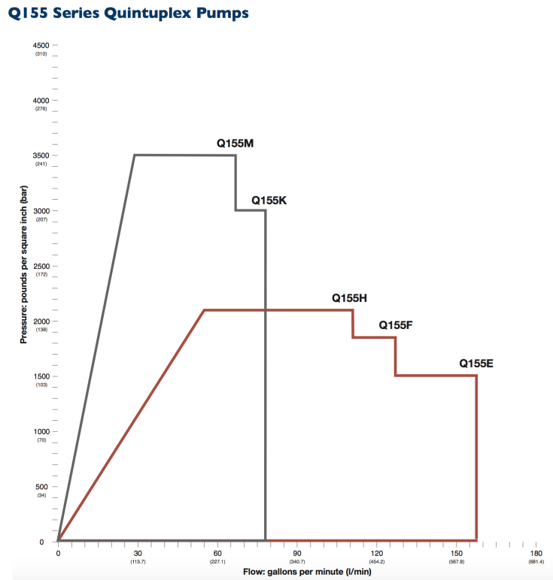

| Q155 Pump Series Low Pressure |

Q155 Pump Series Medium Pressure |

|

Max Flow: 195 gpm |

Max Flow: 78 gpm Max Pressure: 3500 psi (241 bar) |

The graph above displays the maximum flow capacity at a given pressure for each model series. The table below lists the maximum flow capacity and maximum pressure capability of each model series.

Please Note: Some models do not achieve maximum flow at maximum pressure. Refer to the individual model specifications in this section for precise flow and pressure capabilities by specific pump configuration.

| Maximum Capacity gpm (l/min) |

Maximum Discharge Pressure psi (bar) |

Maximum Inlet Pressure psi (bar) |

Maximum Operating Temperature * F (C) |

|

|---|---|---|---|---|

| Q155E | 157 (595) | 1500 (103) | 500 (34) | 180 ̊ (82 ̊ ) |

| Q155F | 127 (490) | 1850 (127) | 500 (34) | 180 ̊ (82 ̊ ) |

| Q155H | 111 (421) | 2100 (144) | 500 (34) | 180 ̊ (82 ̊ ) |

| Q155K | 78 (295) | 3000 (207) | 500 (34) | 180 ̊ (82 ̊ ) |

| Q155M | 67 (252) | 3500 (241) | 500 (34) | 180 ̊ (82 ̊ ) |

* Consult factory for correct component selection for temperatures above 180 ̊ F (82 ̊ C) or below 40 ̊ F (4 ̊ C)

Economical

- Real Savings from using Hydra-Cell Sealless pumps

- Can save approximately 30% to 50% on initial costs because Hydra-Cell Sealless Pumps use lower horsepower motors to achieve the same flow rates and pressures as other pumps.

- Compact design with smaller footprint provides more efficient use of floor space.

- Operates at 85-90% energy efficiency to reduce operating costs.

- Seal-less design reduces maintenance and repair expenditures and minimizes the cost of spare parts compared to other types of pumps.

Capable

- Hydra-Cell Seal-less pumps can deal with abrasive liquids

- Tolerates abrasive solids and particulate matter up to 800 microns (depending on pump model) and 9 hardness (Mohs) without the need for fine filtration.

- Multiple diaphragms provide virtually pulse-less flow that exceeds API 675 standards for accuracy, linearity, and repeatability.

- Low-shear pumping action ensures integrity of long-chain structures.

Environmental

- Hydra-Cell Seal-less pumps are environmentally friendly

- Liquids are 100% sealed from the atmosphere.

- No leak path for toxic vapors or harmful gasses.

- No seals to leak any Volatile Organic Compounds (VOC).

- Lower energy costs to operate pump.

Versatile

- Versatility of Hydra-Cell Seal-less pumps is unmatched

- Variety of styles and models to pump a wide range of flow capacities and pressure ratings.

- Hydraulically-balanced diaphragms can pump low-to-high- viscosity liquids throughout the entire pressure range of the pump.

- Available in a variety of construction materials to meet a wide range of applications and ensure optimum pumping life even when handling aggressive fluids.

- Can be fitted with SAE, ANSI or DIN flanges as well as IEC or NEMA motor mounts.

- Can be provided with ATEX certification or other certification to adapt to specific applications or meet international standards.

- Design allows for easy interchangeability of pump head materials and can accommodate mixing different materials with one pump head.

Reliable

- Hydra-Cell Seal-less pumps are most reliable

- Can run dry without damage to the pump.

- Robust design tolerates non-ideal operating conditions.

- No seals, packing or cups to leak or replace.

- Typically runs up to 6,000 hours between lubricating oil changes.

- Can pump acids, slurries and liquids containing up to 40% of non-dissolved solids.

- Does not rely on the fluid being pumped for lubrication.

- No tight tolerances susceptible to corrosion or solid particles.