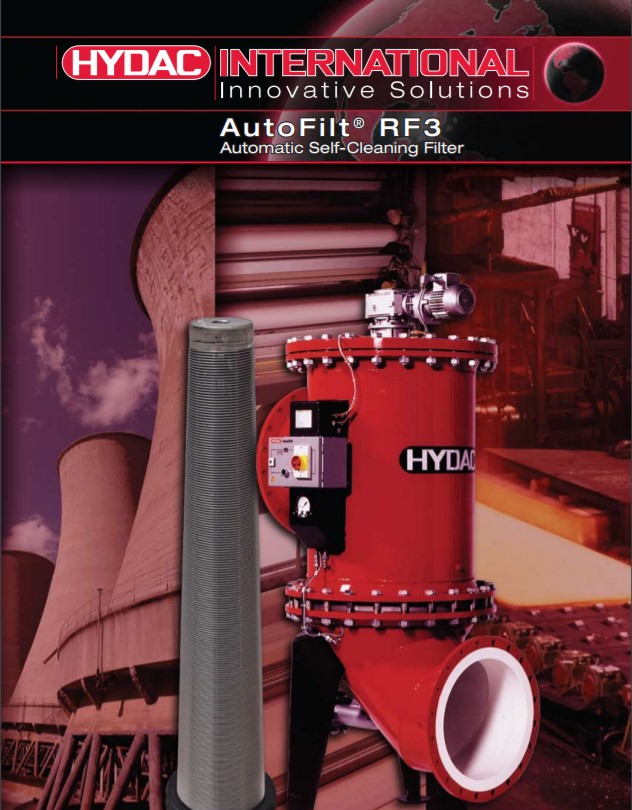

HYDAC AutoFilt RF3 Automatic Self-Cleaning Strainer is a self-cleaning system for extracting particles from low-viscosity fluids. The principle application is the filtration of industrial water either as the main filter or as an offline filter. Its robust construction and automatic back-flushing capability make a major contribution to operational reliability and reduce operating and maintenance costs.

When designing the filter, state-of-the-art methods of flow simulation were employed. As a result the new conical slotted tube filter elements in stainless steel ensure highly effective separation of contamination particles with filtration ratings of 25 to 3.000 µm.

The contamination condition of the elements is monitored by means of differential pressure measurement. When the filter reaches a certain pressure drop, automatic cleaning begins, during which all the filter elements in turn are back-flushed with a small volume of fluid without interrupting the flow of filtrate. The special shape and arrangement of the conical filter elements allows an even flow through the filter, resulting in a low pressure drop and complete cleaning of the elements.

Advantage: fewer back-flushing cycles, low back-flushing drop.

Since the control parameters and flange positions can be customised, and because of the large number of equipment and material options, the system can be integrated into any process.

Cost-effectiveness of the HYDAC AutoFilt RF3 Automatic Self-Cleaning Strainer:

Particle contamination in operating fluids accelerates the rate of wear of system components, pipelines and valves and often leads to their premature failure. In many cases, the use of automatic back-flushing filters leads to a significant increase in service life and maintenance intervals. Costs for new purchases, maintenance and waste disposal can thus be minimized.

Applications for HYDAC AutoFilt RF3 Automatic Self-Cleaning Strainer:

- Power stations: Treatment of industrial water for cooling generators and filtration of sealing water to increase the service life of the turbine shaft sliding-ring seals in hydroelectric power stations.

- District heat supply: Protecting heat exchangers from clogging and wear.

- Chemical industry: Improving product quality by filtering process media.

- Steel industry: Protection of nozzles and pumps during high-pressure descaling, water treatment for cooling blast furnaces and rolling mills.

- Sewage treatment plants: During production of industrial water, filtration of a take-off of the clear run can be used to save valuable drinking or well water.

- Environmental technology: Back-flushing filters are used as pre-filters before waste-water treatment plants (UV treatment, reverse osmosis, membrane filtration).

- Mining: By filtering underground, spray water of an even quality is assured. This results in more reliable operation of pumps and disc-cutting machines.

- Paper industry: For example: the protection of spray nozzles for the screens of paper-making machines. This results in fewer failures caused by clogging and wear.

- Automotive industry, Mechanical engineering, Machine tools: Cooling lubricant emulsions can be kept much longer in circulation. This eases the pressure on the environment and reduces waste-disposal and re-purchasing costs. Filtering of cooling and service water protects cooling channels and pipelines from clogging.