Gosco S-Class Vari-V Control Valves Overview

When you require precise control of flow, pressure or temperature, the Gosco S-Class Vari-V Control Valves provide exactly what you need. Standard 10°, 30°, 60°, 90° V’s are cut into the ball to handle the majority of control requirements. Custom profile V’s are used for unusual applications requiring special flow characteristics.

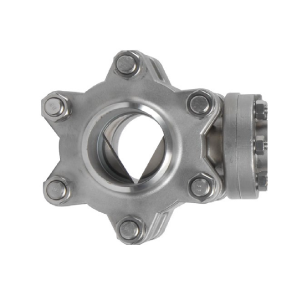

Vari-V Balls

At the heart of every Gosco S-Class Vari-V Control Valves lie the Vari-V ball. The profile of the Gosco determines the flow characteristic of the valve, and can be changed to suit the application. 10°, 30°, 60° and 90° Gosco Vari-V balls are most common, but other profiles such as a Linear-V, Filler-V and High Turndown-V are also available. Gosco S-Class Vari-V Valves are made specifically for your flow conditions – we have a valve to suit your application, with no compromises.

Custom Vari-V Balls

Custom Vari-V balls are available for applications that require specific flow requirements which can’t be met using Gosco’s standard Vari-V balls. With the aid of Computational Fluid Dynamics (CFD), we can create a Vari-V ball with a specific profile to fit any requirement, including high turndown applications. We’ve made custom Vari-V balls with slots that are almost as thin as a human hair. A Vari-V Valve with a custom “V”, is a bespoke valve that will handle ANY process flow condition.

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a flow simulation software package that can be used to identify high velocity flow paths within our valve. If these velocities are high enough to cause cavitation or damage to the valve, special design elements can be added to reduce/manage the velocities. CFD was used in conjunction with real flow testing to determine the flow coefficient (Cv) of Gosco’s standard Vari-V balls. It is also used to design custom Vari-V balls, where unique flow characteristics are required for the service.

Shaft Sealing System

The core of our patented shaft sealing system is the dual live-loaded packing. To eliminate side loading on the packing, we’ve added two shaft guides to support the shaft at the bottom and the top. For a third layer of protection, a fugitive emissions port can be drilled to monitor the areas between the packing sets. Gosco’s shaft sealing system has been tested by TUV, and exceeds all current and projected fugitive emission standards.

Encapsulated “Soft” Seats

Gosco S-Class encapsulated soft seats are used for high cycle, abrasive, and high pressure/temperature applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the “Soft” material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the max pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball. For abrasive applications, it can be used in conjunction with a boronized, arcuate cut ball.

Exotic Alloys

Cast, forged or bar stock, Gosco manufactures ball valves out of any metal – even specialty metals that require vacuum casting (like titanium). We are not restricted to making just the body from exotic alloys – we can manufacture any component to suit your needs, right down to the bolting. Our engineering team at Gosco Valves has extensive experience in corrosive applications, and can recommend the appropriate material to use for specific media.

Extended Bonnet

The extended bonnet is perfect for insulated lines as there is at least 2″ between the top of the flange and the bottom of the Clearview mounting pad. This allows you to fully insulate the valve and still have access to make packing adjustments, without having to remove the actuator or insulation. The valve shaft flats are also visible, and the actuator is raised away from the elevated process temperatures, preventing damage to the actuator seals.

Clearview Mounting Pad

The Clearview mounting pad is a combination of an ISO 5211 mounting pad for easy installation of valve accessories, and a CNC machined/cast bracket that guarantees accurate actuator alignment. Packing adjustments can be performed in-line without removing the actuator, and the double “D” shaft gives you a visible indication of the position of the valve. Clearview also raises the actuator away from the valve, and acts as a heat sink to protect it from high temperatures.

-

Vari-V Sizes

NPS ½ FP to NPS 16 SP

½″ FP to 16″ SP -

Vari-V Connections

150# to 4500#, NPT, SW

BW, Graylock and Custom -

Vari-V Configurations

On/Off, Vari V, Cryogenic, Double Isolation & Bleed

-

Vari-V Temperatures

-50°C to 260°C

-58°F to 500°F