Gosco F-Class Vari-V Control Valves Overview

When you require precise control of flow, pressure or temperature, Gosco F-Class Vari-V Control Valves provide exactly what you need. Standard 10°, 30°, 60°, 90° V’s are cut into the ball to handle the majority of control requirements. Custom profile V’s are used for unusual applications requiring special flow characteristics.

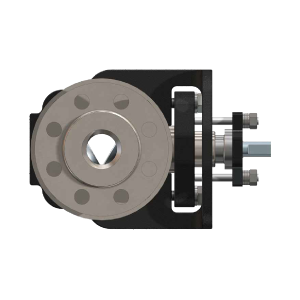

Standard V-Balls

At the heart of every Fab Vari-V Control Valve is the Vari-V ball. The profile of the Vari-V ball determines the flow characteristic of the valve, and can be changed to suit the application. 10°, 30°, 60° and 90° Vari-V balls are most common, but other profiles such as a Linear-V, Filler-V and High Turndown-V are also available. Gosco Vari-V Valves are made specifically for your flow conditions – we have a valve to suit your application, and you don’t compromise.

Custom V-Balls

Custom Vari-V balls are available for applications that possess specific flow requirements which can’t be met using a standard Vari-V ball. With the aid of Computational Fluid Dynamics (CFD),

we can create a Vari-V ball with a specific profile to fit any application. Anti-cavitation trim is also available. For further information on custom V-ball applications, including videos and specifications, please contact Gosco Valves.

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a flow simulation software package that can be used to identify high velocity flow paths within our valve. If these velocities are high enough to cause cavitation or damage to the valve, special design elements can be added to reduce/manage the velocities. CFD was used in conjunction with real flow testing to determine the flow coefficient (Cv) of our standard Vari-V balls. It is also used to design custom Vari-V balls, where unique flow characteristics are required for the service.

Exotic Alloys

We matched all the internals of the Fab Valve to the most corrosion resistant spring material on the market – Inconel 718. The four components that are left can be manufactured from any commercially available metal, including Hastelloy, Inconel, Titanium, Tantalum, Monel, Alloy 20, Duplex, etc. The horseshoe body plates for bolting containment never come in to contact with the process media, so they’re cast from less expensive ASTM A217 Grade WC6 material. You get an exotic alloy valve for less money, and you have the same Gosco quality.

Superior Trim Hardening

BORONIZING is a thermo-chemical surface hardening process that creates a surface layer that’s so hard, it can’t be measured on the Rockwell C Scale. We use Inconel 718 because it is the best overall metal for corrosion, high temperature, and wear resistance. Our PROPRIETARY BORONIZING has a layer depth over 100 microns (0.004”) and a hardness between HV 2500-2700.

Compared to HVOF coatings, BORONIZING is:

Substantially harder, markedly more wear resistant, impervious to corrosion, and is capable of handling huge temperature shocks without spalling or flaking.

Encapsulated “Soft” Seats

The Fab Valve encapsulated “Soft” seats are used for high cycle, abrasive, and high pressure/temperature applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the “Soft” material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the maximum pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball. For abrasive applications, it can be used in conjunction with a boronized, arcuate cut ball.

Seat/Spring Design

Gosco’s patented seat/spring design is perfect for powder/catalyst applications. When powder gets trapped in the spring cavity, it causes the valve to “lock up”. To solve this issue, Gosco uses a completely different approach to the competition – instead of trying to seal the spring from the media, we deliberately open up the cavity around the spring. This allows the media to flow around the spring, but also allows it to escape just as easily. Media never gets trapped in the valve, so we never have issues with valves “locking up”.

Dual Shaft Packing

Gosco Fab Valves have a live loaded upper packing set, Smartpak lower packing, and upper & lower shaft guides to support the shaft and prevent side-loading. The Gosco

shaft sealing system is the best in the world and exceeds all fugitive emission standards.

-

Vari-V Sizes

NPS ½ FP to NPS 8 SP

½″ FP to 8″ SP -

Vari-V Connections

150#, 300#, 600#, NPT,

SW, butt weld & Custom -

Vari-V Configurations

On/Off, Vari-V Control,

Double Isolation & Bleed -

Vari-V Temperatures

-50°C to 593°C

-58°F to 1100°F