Permanently Installed Aseptic Impingement Tank Cleaner

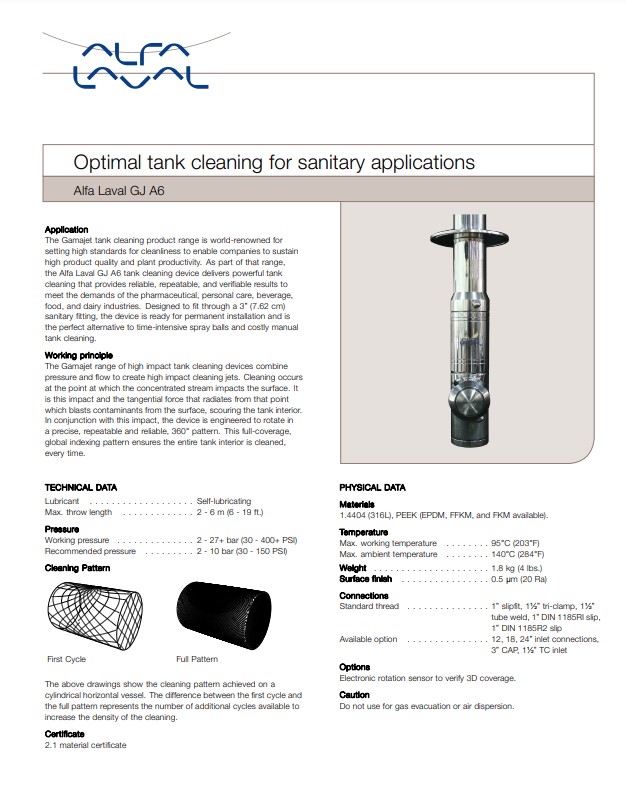

Alfa Laval Gamajet GJ A6 Tank Cleaning Machine is designed for permanent installation and to provide true germ and bacteria-free cleaning to meet the demands of the food, beverage, pharmaceutical and personal care products industries.

The design of the GJ A6 Tank Cleaning Machine completely eliminates all areas for potential bacteria growth making it ideal for sanitary cleaning applications. Variable flow rates and a consistent 360 degree spray pattern ensure reproducible and repeatable cycles that provide thorough and verifiable cleaning. Its compact size fits through a standard 3” (76.2 mm) sanitary fitting, and its light weight makes for easy handling and maneuverability.

The Alfa Laval GJ A6 Tank Cleaning Machine is patented and represents the first validatable method of providing true aseptic tank cleaning from a permanently installed impingement cleaner for sanitary applications.

Benefits:

- Highly sanitary in design

- Fits through a 3 in. sanitary fitting (2.80 in. or 71 mm clearance)

- Powerful: 10 lbs (4.5 kg) of cleaning force at 5 ft. (1.5 m)

Operating Range:

- Pressure: 30 to 400 psi (2 to 27 bar)

- Temperature: 32° to 205°F (0° to 95°C)

- Flow Rate: 5 to 35 gpm (19 to 130 l/min)

- Cleaning Radius: 5 ft. (1.5 m)

- Wash Cycle Time: 10 to 14 min.

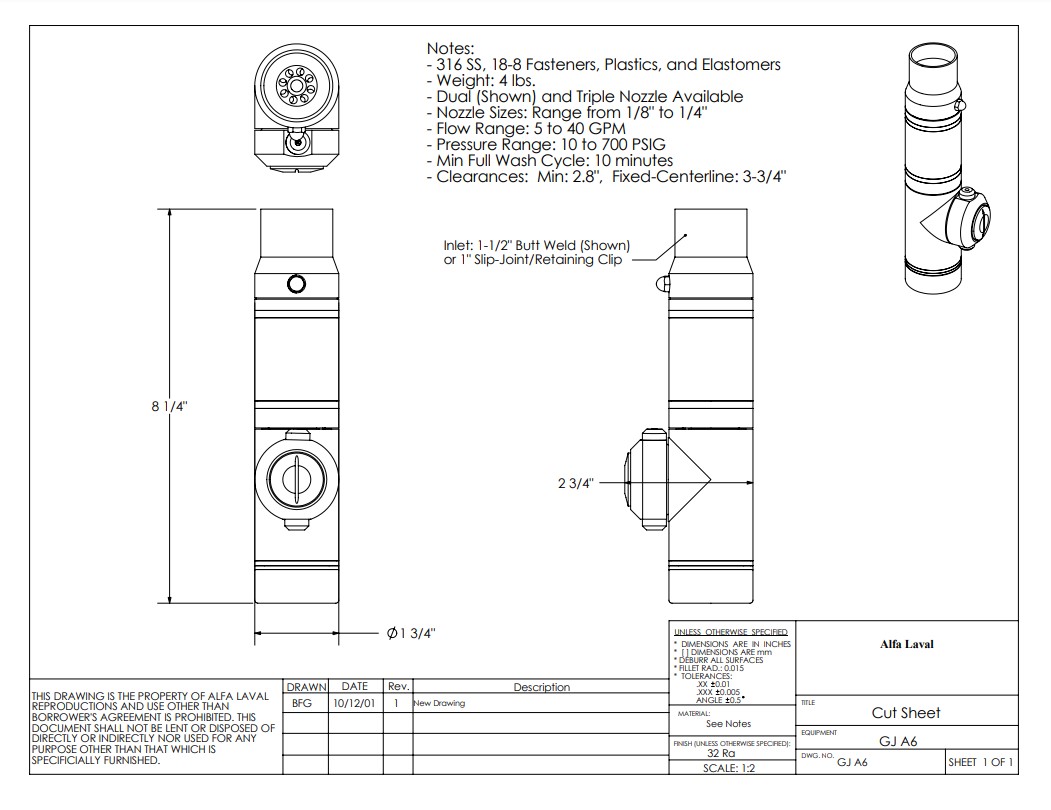

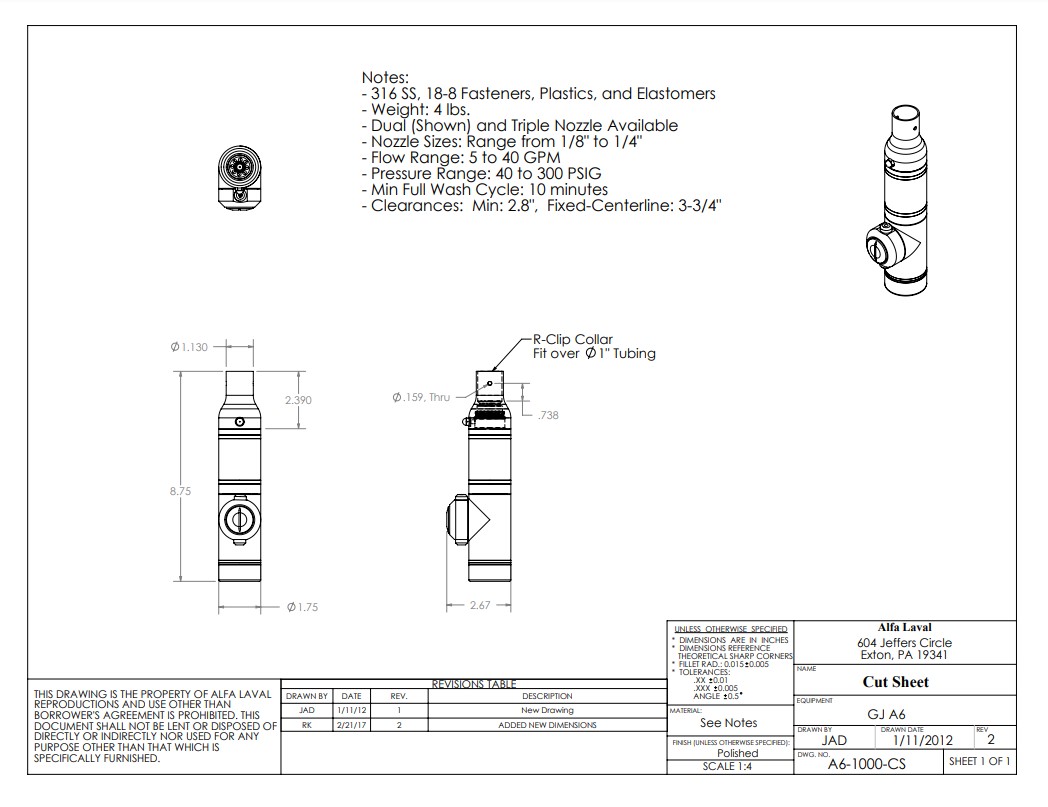

Overall Dimensions:

- Height: 8.75 in. (233 mm)

- Body Diameter: 1.75 in. (44 mm)

- Overall Width: 2.7 in. (69 mm) including nozzle housing

- Clearance: 2.80 in. (71 mm) minimum passageway I.D.

- Weight: 4 lb (1.81 kg)

Other Options:

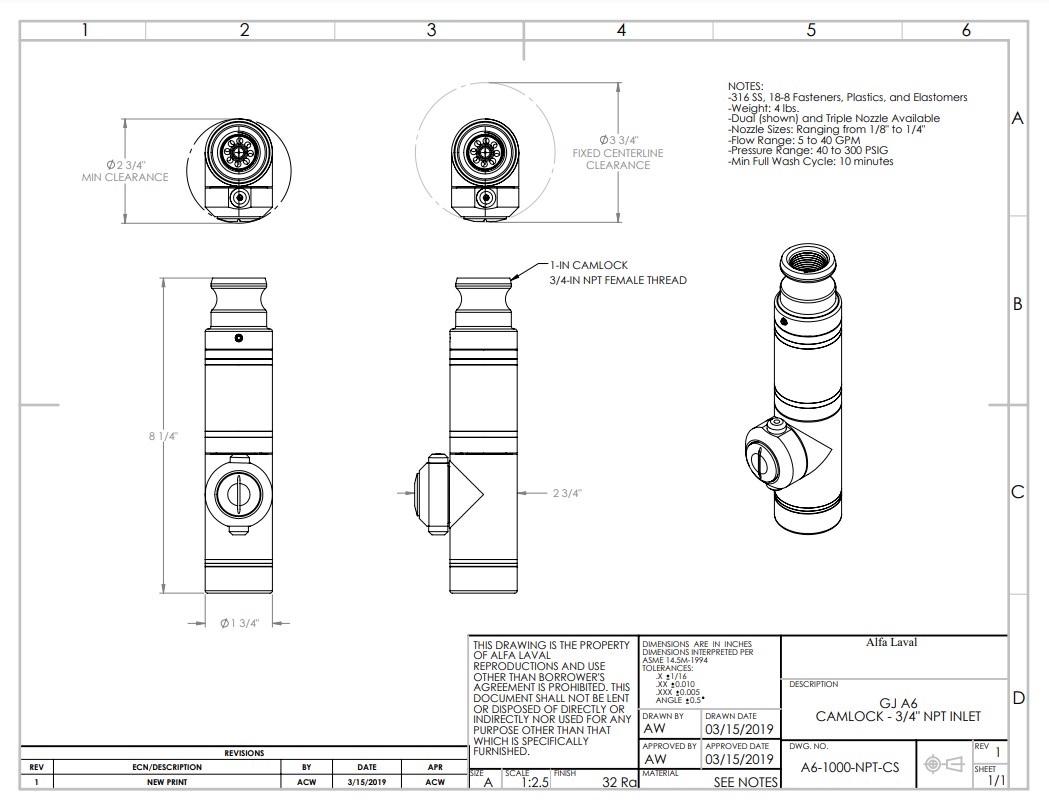

- Dual and triple nozzles

- Varying Sanitary Inlet Adaptors Available

Specifications:

| Inlet Connection: | Connections include 1 1/2 in. Butt Weld Tube or 1 in. Slip-Joint and Retaining Clip. |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the rotor shaft is plasma-sprayed with a Chromium Oxide coating on stainless steel. |

| Shaft & Gearbox Bushings: | Input shaft thrust is absorbed by a Tungsten carbide bushing. Gearbox bushings are PEEK. |

| Bearings: | Bearings in the rotating tee and nozzle housings are self-lubricating, PEEK. |

| Bearing Cups: | Main body castings are protected by replaceable 316-L stainless steel cups for extended frictional wear life. |

| Nozzle Carrier: | Dual or Triple Nozzles |

| Nozzles: | Dual or triple 0.125 in. (3.2 mm) to 0.225 in. (5.7 mm) orifice diameters. Other nozzle sizes are available upon request. |

| Drive Mechanism: | The wash fluid enters the GJ A6 at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the input shaft. The bottom of this shaft is connected to the inside of a flow-through, planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The flow-through planetary gearhead incorporates all stainless steel components. |

| Lubricant: | The GJ A6 is a non-lubricated, contaminant-free unit and does not contain any lubricants. No customer-supplied or user-maintained lubricant is needed. |

| Gear Ratio: | 256: 1 |