Flow-Through Sanitary Tank Cleaning Machine

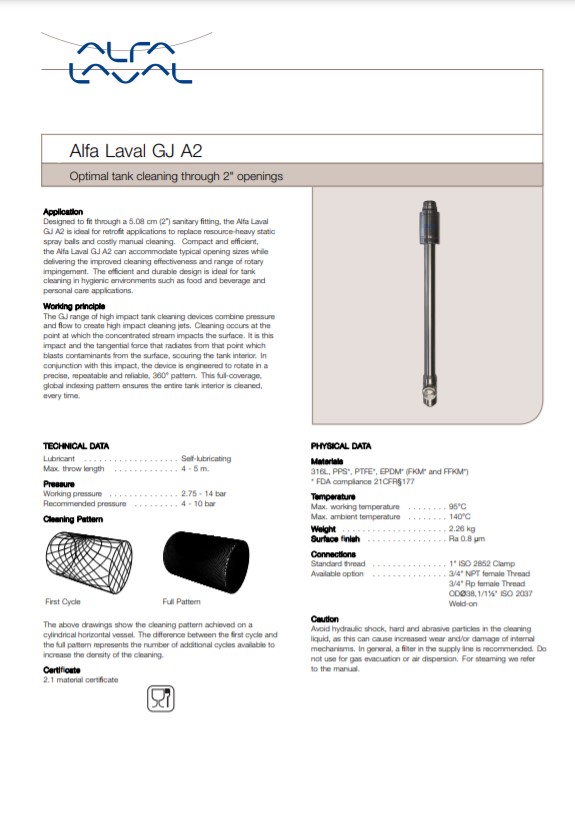

The Alfa Laval Gamajet GJ A2 (Aseptic 2) was created as a solution for pharmaceutical cleaning needs but works cohesively in any sanitary environment.

Self-cleaning, self-flushing, and self-lubricating – the machine requires no oil or grease in the gear train and can withstand higher flow rates resulting in higher impact cleaning. It is also designed to operate with purified water sources. Capable of both permanent and portable installation, the GJ A2 is ideal for effective cleaning of small tanks up to 10 ft. in diameter in a repeatable and reliable 360˚ pattern. Like other Alfa Laval Tank Cleaning Machines, the GJ A2 is entirely fluid-driven with no external motors therefore eliminating the need for power assistance.

Benefits:

- Sanitary design

- Fits through a 2 in. standard sanitary fitting

- Available with an adjustable Tri-Clover® tank connection

- Operates at low pressures

Operating Range:

- Pressure: 40 to 200 psi (3 to 14 bar)

- Temperature: 32° to 200°F (0° to 93°C)

- Flow Rate: 5 to 30 gpm (19 to 114 l/min)

- Cleaning Radius: 5 ft. (1.5 m)

- Wash Cycle Time: 4-20 min.

- Impact: 7 lbs (3 kg) at 5 ft. (1.5 m)

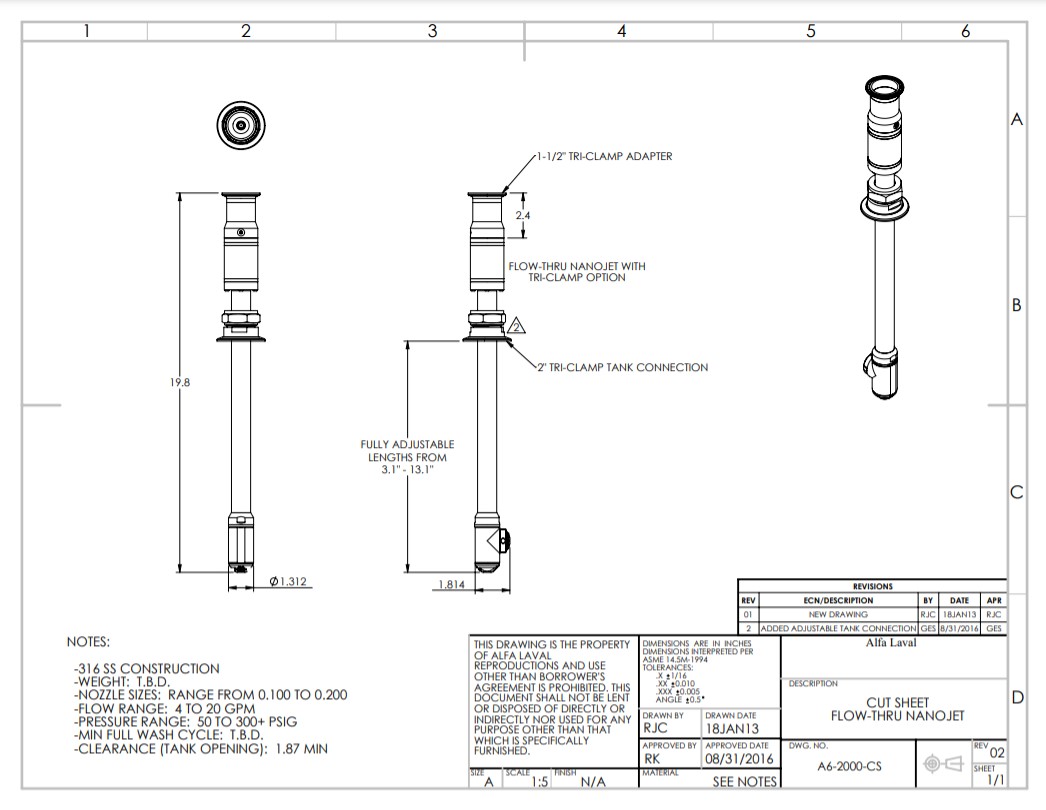

Overall Dimensions:

- Height: 20 in. (508 mm)

- Body Diameter: 1.8 in. (46 mm)

- Weight: 5.5 lb (2.5 kg)

- Clearance:1.87 in (48 mm)

Specifications:

| Inlet Connection: | 1 in. or 1.5 in. Tri-Clover |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the rotor shaft is plasma-sprayed with a Chromium Oxide coating on stainless steel. |

| Shaft & Gearbox Bushings: | Turbine shaft thrust is absorbed by a Tungsten carbide bushing. Gear bushings are carbon filled polyphenylene sulfide. |

| Elastomers: | O-Ring materials are selected for each application. EPDM is standard with Kalrez and Viton available. Other materials can be supplied on special order. |

| Dynamic Seals and Bearings: | Rotary bearings are made of PEEK and PPS. |

| Nozzles: | Dual or quad Nozzle sizes from 0.1 in. (2.54 mm) to 0.2 in. (5.1 mm) |

| Drive Mechanism: | The wash fluid enters the GJ A2 at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the drive or rotor shaft. The bottom of this shaft is connected to the inside of a robust planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | Comprised of all stainless components. 316 stainless steel and 17-4 heat treated stainless components. |

| Lubricant: | None |