The Most Powerful Industrial Tank Cleaning Machine from Alfa Laval

Alfa Laval Gamajet GJ 4 tank cleaning machines are designed to clean larger-sized tanks with diameters from 15 to 100+ ft. (30+ m). The GJ 4 is a hydraulically driven rotary tank cleaning machine that revolves 360° in both horizontal and vertical planes. Synchronized solid jets provide a tight and thorough scouring pattern covering all interior tank surfaces in one complete cycle.

The GJ 4 is available in stainless steel with a choice of oil-lubricated or flow-thru (wash fluid lubricated) gearboxes. Gear trains are designed to maximize wear life which offers improved reliability and reduced downtime.

With a choice of twelve nozzle sizes, various hydraulic turbines and stators along with two gear systems, the GJ 4 offers a wide operating range of flow rates, nozzle rotation speeds, and wash cycles. The GJ 4 is fully capable of high concentration chemical recirculation cleaning or high pressure/low volume water jet scrubbing in fixed CIP automated systems.

Options Include:

- Directional Option – Learn More

- Sidewinder Horizontal Cleaner – Learn More

GJ 4 Benefits:

- Powerful: Up to 100 lbs (45 kg) of cleaning force

- Cleans up to a 100 ft (60 m) radius

- Heavy-duty, durable design

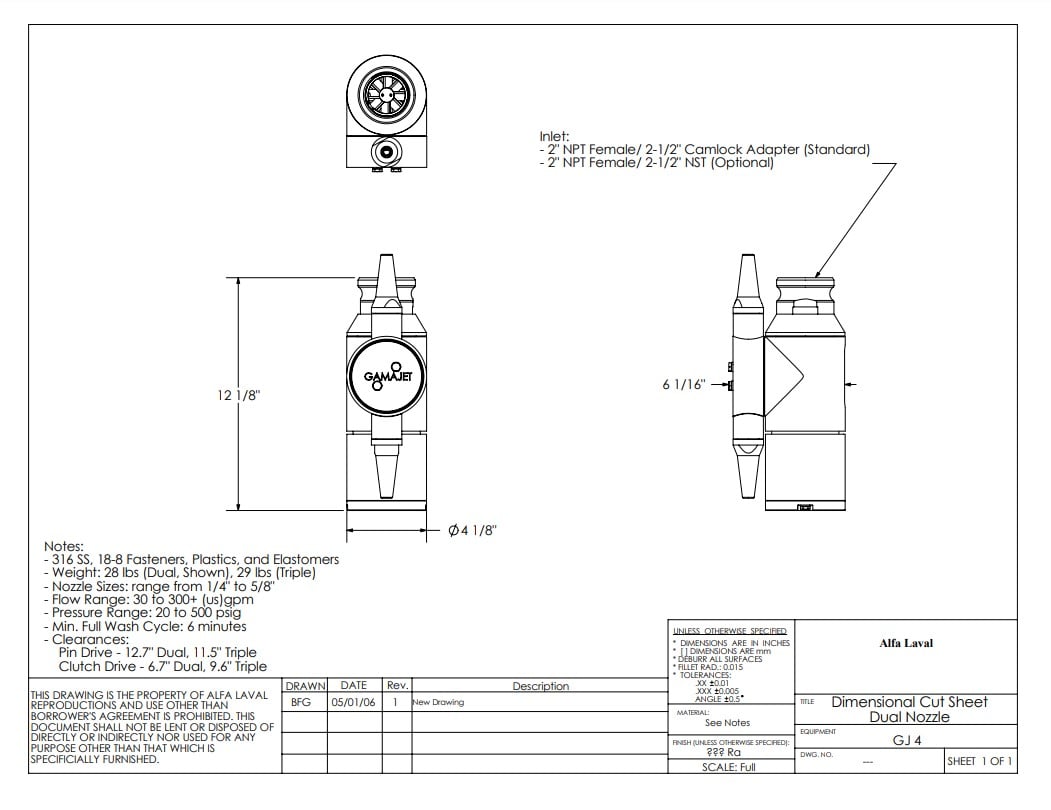

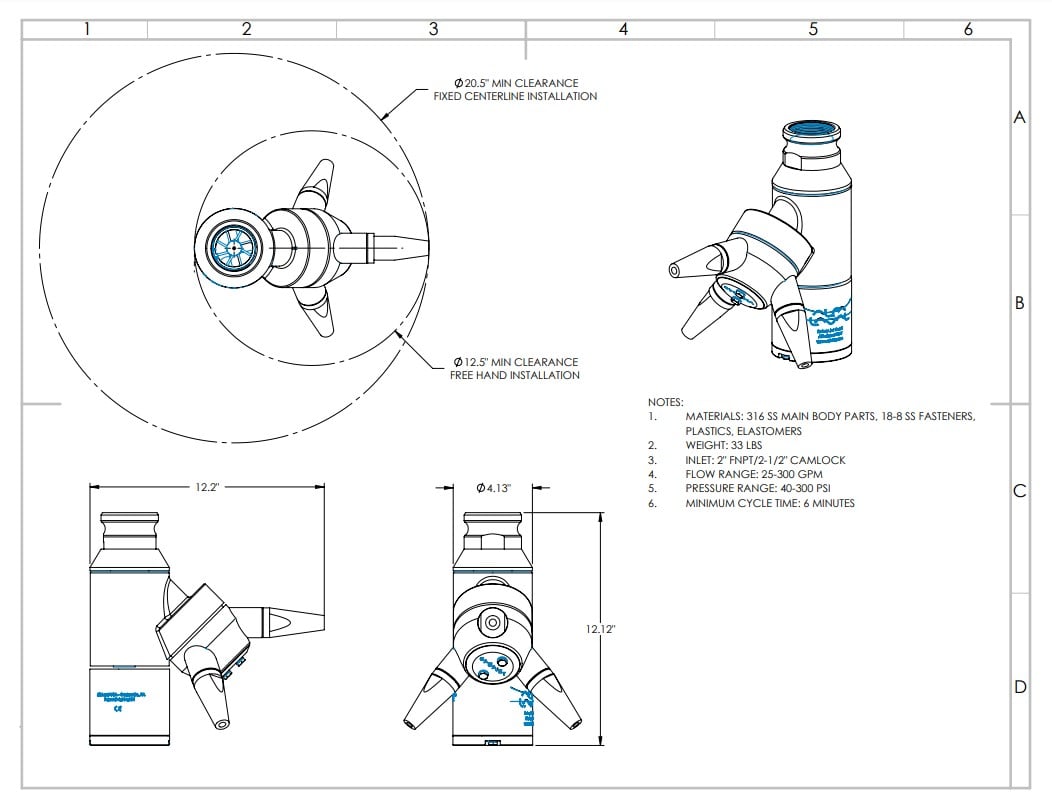

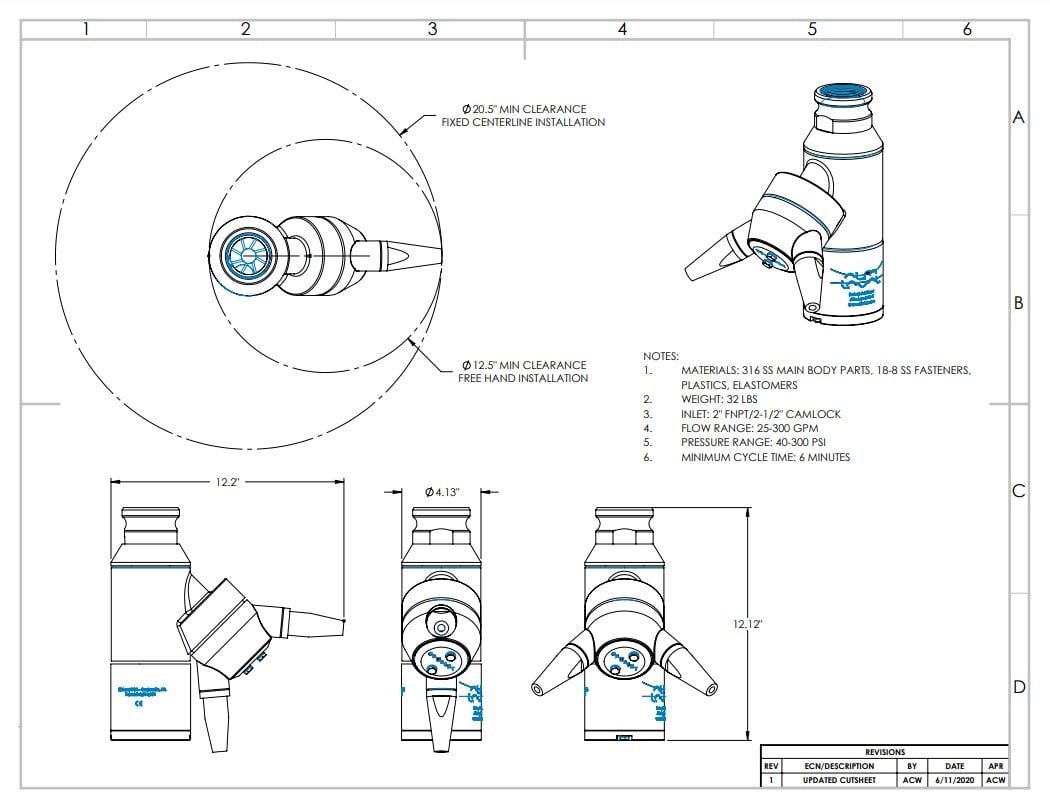

Overall Dimensions:

- Height: 12.2 in. (310 mm)

- Diameter: 4.2 in. (107 mm)

- Width: 6.1 in. (155 mm) including nozzle housing

Clearance Dimensions:

- Pin Drive:

Dual: 12.7 in. (323 mm)

Triple: 11.5 in. (293 mm)

- Optional Clutch Drive:

Dual: 6.7 in. (171 mm)

Triple: 9.6 in. (244 mm)

Operating Range:

- Pressure: 40 to 300 psi (3 to 20 bar)

- Temperature: -60° to 250°F (-29° to 121°C)

- Flow Rate: 30 to 320 gpm (114 to 1211 l/min)

- Cleaning Radius: 100 ft. (30 m)

- Wash Cycle Time: 3 to 30+ min.

- Impact: 85 lbs (39 kg) at 25 ft. (7.5 m)

Weight:

- Dual: 28 lb (12.7 kg)

- Triple: 29 lb. (13.2 kg)

Inlet Connections:

- Standard: 2 in. NPT female and 2 1/2 in. quick disconnect male

- Optional: 2 in. BSP female and 2 1/2 in. quick disconnect male

- Optional: 2 in. NPT female and 2 1/2 in. NST (NH) hose thread male

Specifications:

| Construction/Design: | New Features: Streamlined turbine and internal flow passages, including a patented porting design that significantly improves efficiency. |

|---|---|

| Castings: | Investment cast parts of type 316 stainless steel ensure consistent strength & quality for higher pressure ratings. |

| Rotor & Gearbox Shafts: | Rotor shaft and gearbox shafts are made of hardened stainless steel. For increased wear resistance, the rotor shaft is supplied with a plasma-sprayed ceramic or other protective coating. The rotor shaft is also fitted with a polished carbide thrust washer for added durability. |

| Bearings: | Rotor shaft bearings are tungsten carbide. Gearbox shaft bearings in flo-thru (oilless) gearboxes are PTFE or other non-cupric materials. Standard bearings in oil-lubricated gearboxes are Oilite bronze with nonmetallic bearings available as an option. |

| Static Seals: | O-Ring materials are selected for each application. Viton® is standard. |

| Gears: | All gears are manufactured entirely of selected stainless steel alloys and the two bottom gears are fitted with long-life tungsten carbide thrust washers. |

| Gearbox: | The flo-thru gearbox is lubricated by the cleaning solution. With this option, maintenance of gearbox seals is eliminated. Oil-lubricated machines have a sealed gearbox filled with FDA approved oil. |