EXAIR High Temperature Air Amplifiers are rated to 700°F (374°C) and made to circulate air in hot environments including inside ovens, furnaces and large molds. Utilizing the Coanda effect, a basic principle of fluidics, Air Amplifiers become a simple, low cost way to circulate air, move smoke, fumes and light materials. Using a small amount of compressed air as their power source, High Temperature Air Amplifiers pull in large volumes of surrounding air to produce high volume, high velocity outlet flows through a fixed air gap. They are quiet and efficient while creating output flows up to 25 times their consumption rate.

Applications:

- Vent welding smoke

- Cool hot parts

- Dry wet parts

- Clean machined parts

Advantages:

| Compared to Fans: | Compared to Venturies and Ejectors: |

|

|

High Temperature Air Amplifier Performance:

| 80 PSIG (5.5 BAR) | Air Consumption | Amplification | Air Volume at Outlet | Air Volume at 6inch (152mm) | Sound Level | |||

| Model # | SCFM | SLPM | RATIO | SCFM | SLPM | SCFM | SLPM | dBA |

| 121021 | 8.1 | 229 | 18 | 146 | 4,132 | 436 | 12,339 | 72 |

Tested with .003inch (0.08mm) shim.

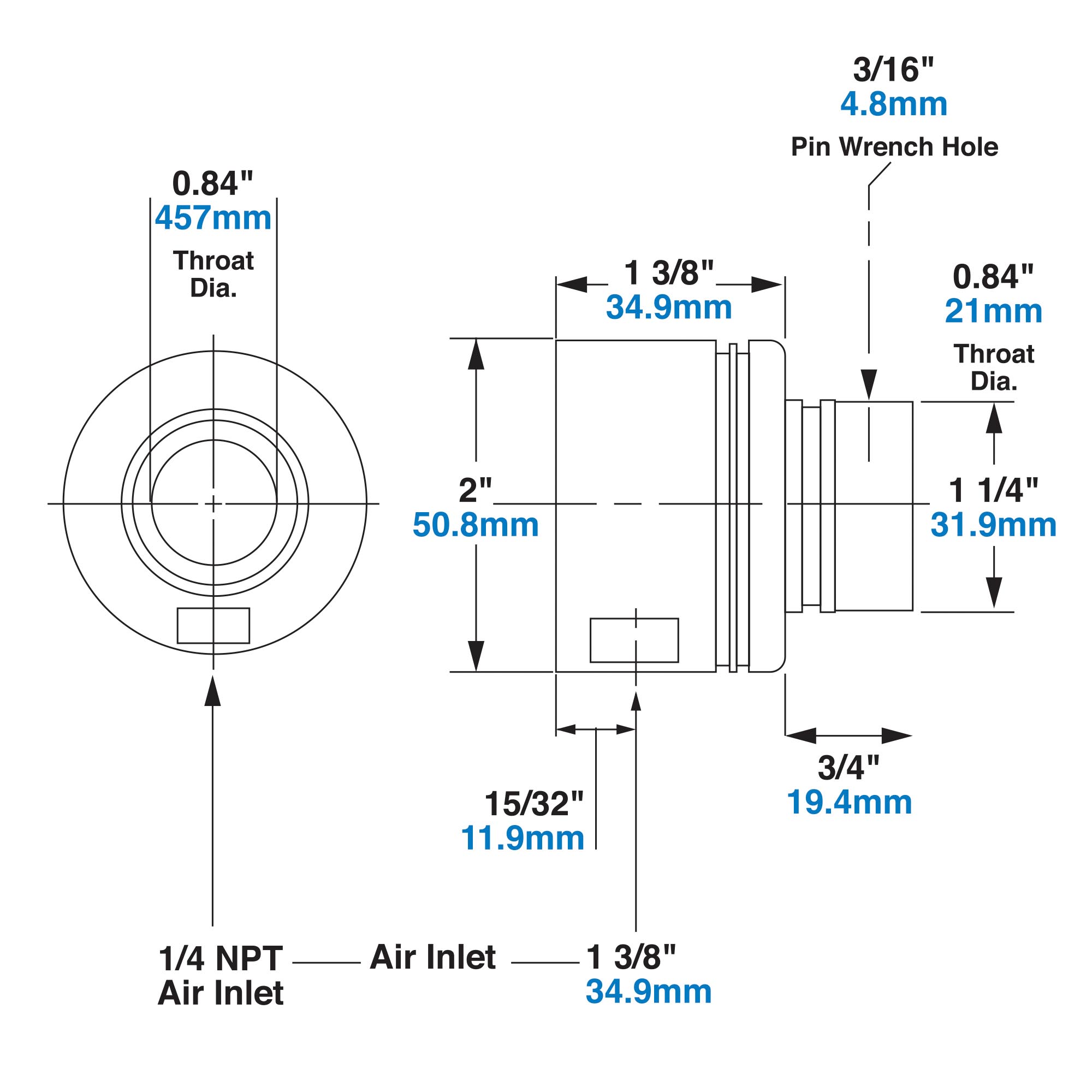

High Temperature Air Amplifier Dimensions:

Model 121021 - High Temperature Air Amplifier:

| A | in | 0.84 |

| mm | 21 | |

| B | in | 0.94 |

| mm | 24 | |

| C | in | 1.50 |

| mm | 38 | |

| D | in | 2.40 |

| mm | 61 | |

| E | in | 3.03 |

| mm | 77 | |

| F | in | 0.27 |

| mm | 7 | |

| G | in | 0.21 |

| mm | 5 | |

| H | in | 0.75 |

| mm | 19 | |

| J | in | 1.22 |

| mm | 31 | |

| K | in | 2.88 |

| mm | 73 | |

| L | in | 0.59 |

| mm | 15 | |

| M | NPT | 1/4 |

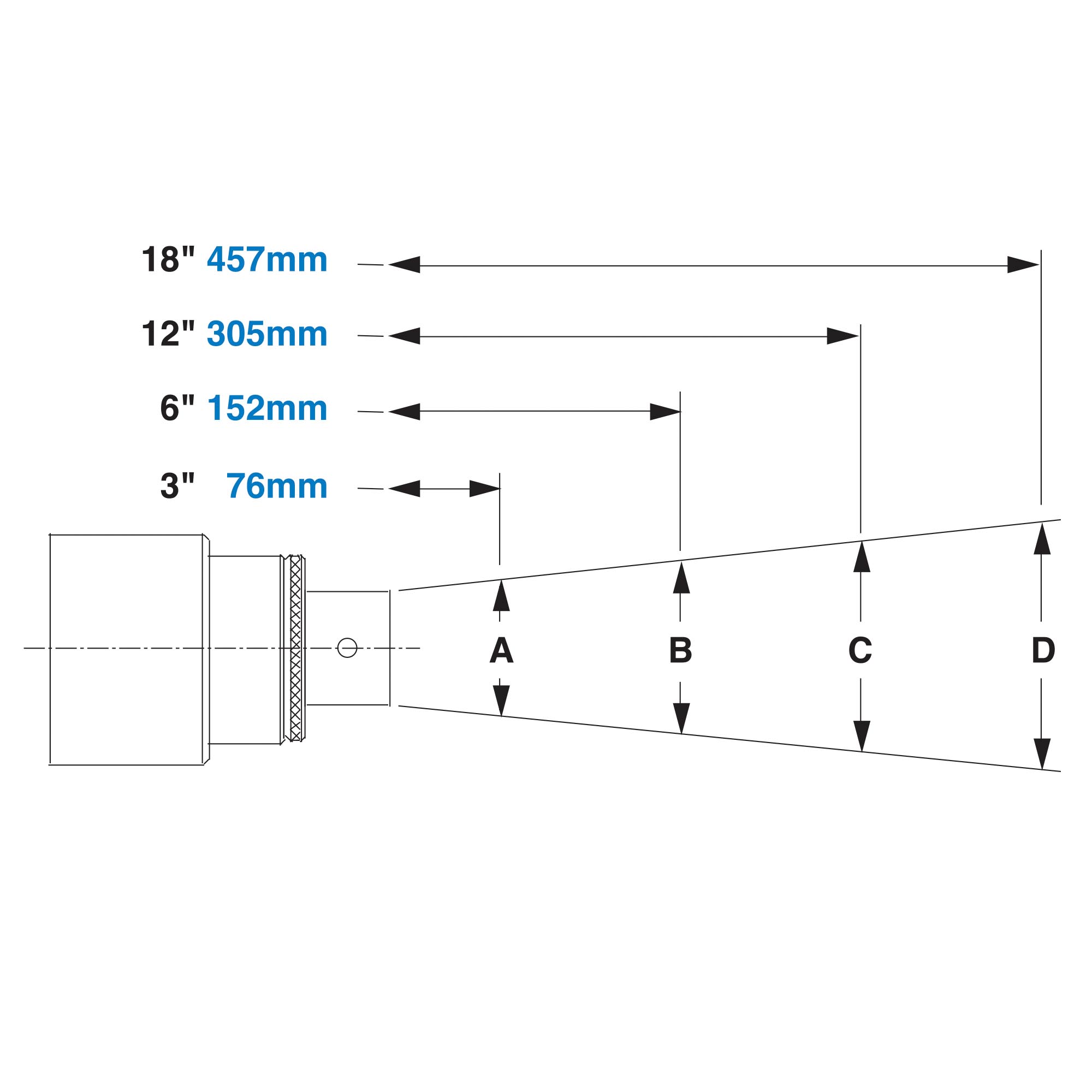

High Temperature Air Amplifier Airflow Pattern:

Model 121021 - High Temperature Air Amplifier:

| A | in | 2 |

| mm | 51 | |

| B | in | 2.9 |

| mm | 74 | |

| C | in | 4.7 |

| mm | 119 | |

| D | in | 6.5 |

| mm | 165 |

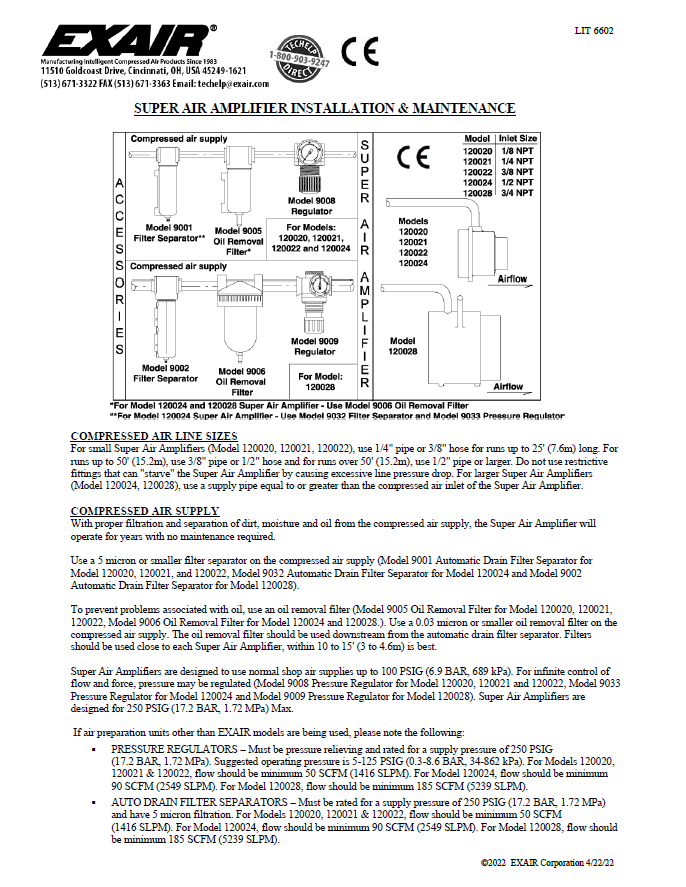

How Air Amplifiers Work:

Compressed air flows through the air inlet (1) into an annular chamber (2). It is then throttled through a small ring nozzle (3) at high velocity. This primary airstream adheres to the Coanda profile (4), which directs it toward the outlet. A low pressure area is created at the center (5), inducing a high volume flow of surrounding air into the primary airstream. The combined flow of primary and surrounding air exhausts from the Air Amplifier in a high volume, high velocity flow.

High Temperature Air Amplifier Standards and Certifications

EXAIR Air Amplifiers comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC).All sound level measurements are taken at 3 feet away.

EXAIR Air Amplifiers comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC).All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.