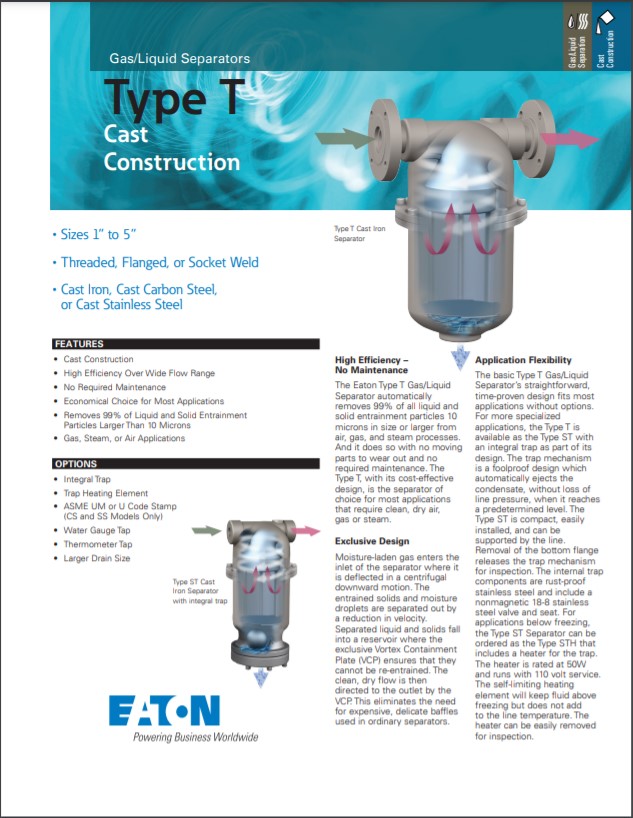

Eaton T ST Cast Gas Liquid Separators are available with an integral trap as part of its design (Type ST). The trap mechanism is a fool-proof design which automatically ejects the condensate, without loss of line pressure, when it reaches a predetermined level. The Type ST is compact, easily installed and can be supported by the line.

Features of EATON T ST Cast Gas Liquid Separators

- Cast Construction

- High Efficiency Over Wide Flow Range

- No Required Maintenance

- Economical Choice for Most Applications

- Removes 99% of Liquid and Solid Entrainment Particles Larger Than 10 Micron

- Gas, Steam or Air Applications

Options of EATON T ST Cast Gas Liquid Separators

- Integral Trap

- Trap Heating Element

- ASME UM or U Code Stamp

- Water Gauge Tap

- Thermometer Tap

- Larger Drain Size

EATON T ST Cast Gas Liquid Separators High Efficiency – No Maintenance

Eaton T Gas Liquid Separators automatically remove 99% of all liquid and solid entrainment particles 10 microns in size or larger from air, gas, and steam processes. And they do it with no moving parts to wear out and with no required maintenance. The Type T, with its cost effective design, is the separator of choice for most applications that require clean, dry air, gas or steam..

Exclusive Design

Moisture laden gas enters the inlet of the separator where it is deflected in a centrifugal downward motion. The entrained solids and moisture droplets are separated out by a reduction in velocity. Separated liquid and solids fall into a reservoir where Eaton’s exclusive Vortex Containment Plate (VCP) ensures that they cannot be re-entrained. The clean, dry flow is then directed to the outlet by the Vortex Containment Plate. The VCP eliminates the need for expensive, delicate baffles used in ordinary separators.

Application Flexibility

The basic EATON T ST Gas Liquid Separators straight forward, time proven design fits most applications without options. For more specialized applications the EATON T Type is available as the T ST Type with an integral trap as part of its design. The trap mechanism is a foolproof design which automatically ejects the condensate, without loss of line pressure, when it reaches a predetermined level. The Type ST is compact, easily installed and can be supported by the line. Removal of the bottom flange releases the trap mechanism for inspection. The internal trap components are rustproof stainless steel and include a non-magnetic 18-8 stainless steel valve and seat. For applications below freezing the Type ST Separator can be ordered as the Type STH that includes a heater for the trap. The heater is rated at 50W and is for 110 volt service. The self limiting heating element will keep fluid above freezing and does not add to the line temperature. The heater can be easily removed for inspection.

Choose Cast or Fabricated Construction

Type T Gas /Liquid Separators are available in sizes up to 4” in cast iron and up to 2” in cast carbon steel or cast stainless steel with standard configurations. Cast construction separators are readily available but are not easy or cost effective to modify to conform to special application requirements. For these applications see page 10 for Fabricated Type T Separators made of carbon or stainless steel in sizes up to 24”. Because they are constructed to specification they can be easily modified to suit unique applications such as those that require radially rotated inlet and outlet connections. Fabricated separators are not as heavy as cast ones, an important consideration in applications where weight is a concern. Cast or fabricated EATON’s Eaton™ Type T Gas/Liquid Separators let’s you choose the best on for your application.

We Can Help

Choosing the right gas/liquid separator can present unique problems not encountered in choosing other pipeline components. Why not take advantage of Eaton’s over 100 years of application experience with gas/liquid separators? Application specialists are available to help you every step of the way…from initial selection, to installation and through start-up…just contact us.

| SELECTION TABLE | |||

|---|---|---|---|

| Pipe Size (in) | Material | Connection | Rating |

| 3/4 to 3 | Cast Iron | Threaded | 250 psi @ 450° |

| 2 to 4 | Cast Iron | Flg 125# FF | 150 psi @ 353°F | 125 psi @ 450°F |

| 1 to 2 | Cast CS | Thd or Skt Weld | 1000 psi @ 650°F |

| 1 to 2 | Cast SS | Thd or Skt Weld | 500 psi @ 300°F |

| 1 to 24 | Fabricated CS | Flg 150# RF | Flg 300# RF | 150 psi @ 450°F | 500 psi @ 650°F |

| 1 to 24 | Fabricated SS | Flg 150# RF | Flg 300# RF | 150 psi @ 300°F | 500 psi @ 300°F |