EATON ReactoGard V systems for the protection of fixed bed catalytic reactors and related refinery operations are engineered to produce cleaner and more efficient low flux operation. Diverter technology eliminates need for internal valves which increases efficiency and reliability.

How EATON ReactoGard V Catalyst Protection Filters works…

Filter banks run in parallel, with each bank handling a portion of the total process flow.

Unfiltered liquid enters each bank via the inlet, and is distributed evenly to each filter housing.

The liquid flows from the outside of the element to the inside, depositing contaminants on the outside.

Clean liquid exits each bank via the outlet. As contaminants collect on the filter elements, the pressure differential increases.

When the pressure differential reaches a controlled set point on one bank of filters, a pressure switch signals the master controller to isolate the bank and begin the backwash cycle.

Systems are backwashed using filtered liquid or by introducing a separate backwash liquid.

How backwashing (cleaning) works…

When cleaning is required, the system operates without interruption.

A single filter bank that required cleaning is momentarily isolated from the feed flow and purged as the application required.

Then, each filter element on that bank is cleaned sequentially. This method assures that the total backwash energy is directed to individual.

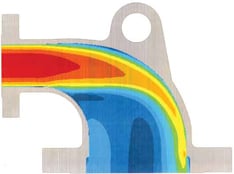

Diverter chamber with precision proximity switch efficiently distributes material flow with fewer moving parts

Available configuration options:

- Internal backwash configuration

- External backwash configuration

- Forward purge configuration

EATON ReactoGard V Systems features include…

- Flanged valves (vs. socket welded valves) in standard ANSI dimensions simplify serviceability and replacement.

- Hardened alloy valve seats offer 4-5 times the life of carbon graphite.

- Actuators are located on valves so there are no mechanical linkages to maintain or adjustments to make.

- All components flanged for enhanced serviceability.

- Systems easily forward purge adaptable when handling high sulphur feeds.

- Programmable Logic Control (PLC) with electronic interface to control rooms provides control flexibility and reliability.