Eaton’s DCF-2000 is designed specifically to address the challenges associated with filtering coatings and slurries in the paper making industry. Eliminate paper-breaks or streaks, reduce

the environmental impact, and maximize uptime and productivity—for high production volumes and consistent product quality. With a rugged motorized cleaning action, the DCF-2000

can handle the continuous processing requirements of protecting critical wet-end coating operations.

Operation of Disc Cleaning FiltersDriven at a constant rate and pressure, the cleaning disc continuously wipes collected debris from the screen. Collected contaminants are agitated in the collection chamber, keeping them in a semi-liquid state, ready to be purged from the system.

EATON DCF 2000 Specifications

| Specifications | DCF-2000 |

|---|---|

| Single Unit Weight | 564 lbs | 256 kg |

| Service Height | 72 in | 1828 mm |

| Total Volumetric Capacity | 11 gal | 41.6 liters |

| Purge Chamber Capacity | 1.5 gal | 6 liters |

| Filtration Surface Area | 610 in² | 3935 cm² |

| Flow Rate Range at 100μ | 30–200 gpm | 6.8–45.4 m3/hr |

| Maximum Temperature* | 160˚ F | 71˚ C |

| Maximum Pressure | 150 psi | 10.5 bar (standard) |

| Electrical for Motor Drive | Single Phase 110/220V, 50/60 Hz for control | Three Phase, 220/380/440/575V (please specify), 50/60 Hz for motor. |

| Electrical for Controllers | Single Phase 110/220V, 50/60 Hz |

* Dependent on elastomer seal selection.

EATON DCF 2000 Mechanically Cleaned Filters Features

- Filters 48-72% solids coatings at 75 micron retention—the tightest in the industry

- Continuously removes contaminants from the coating and efficiently evacuates collected contaminants while operating at a low, constant differential pressure

- Designed for continuous unattended operation—without the need for operator intervention

- Mechanically cleaned media eliminates replacement media cost and the expense and hazard of waste disposal

- Increased profitability—improves system efficiency, reduces paperbreaks and associated downtime

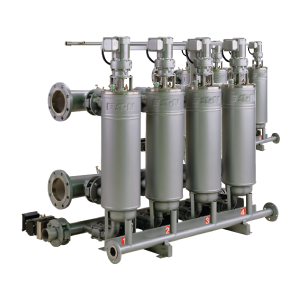

- Multiplex configurations available and valved to a common tapered header for high-flow applications

| SINGLE CONFIGURATION | MULTIPLEX CONFIGURATION |

|

|

Typical Applications:

- Paper Coatings