Custom Spray Nozzle Solutions – High Impact Spiral Tank Washing Nozzle

Application #041606

Industry: Food Processing

Application: High Impact Washing

Product Description: Spiral Tank Wash Nozzle with Back Spray

Situation: The customer had an installation of fryer hoods above conveyor fryers that continually manufactured potato waffles and patties. These products are among the customer’s most profitable lines. Therefore the amount of downtime is critical to the overall profitability of the plant. The existing set-up was a mixture of a competitor’s rotating tank wash nozzles and unbranded fire protection nozzles. Both nozzles were blocking due to particulate that was in the solution of re-circulated caustic the customer was using for washing. The customer had a regular cleaning every 14 days where the line would shut down for 24 hours and two men would spend all day cleaning out the hoods by washing and scraping away the old burnt-on oil. The customer noticed that the rotating nozzles were ceasing to turn and that they were not cleaning effectively. The fire protection type nozzles were completely blocked and did not spray at all.

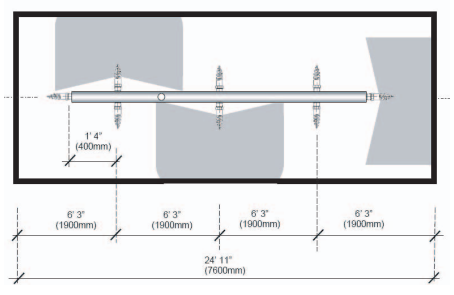

Solution: Bete carried out a survey of the hoods and suggested an array of TW and TFXW tank washing nozzles. The application is more a distribution problem than pure scrubbing of the surfaces as the sprayed solution eats away all of the oil residue. Due to the complexity of some of the steel work inside the hoods, BETE positioned the TFXWs in the shaded areas (see drawing). There was also an area along the side of the hood that meets the conveyor that was continuously clogging. Bete mounted a line of twenty 3/8″ TW20s to distribute the solution along the sides. In another hood, there was a lot less shading and the depth of the hood put the base of the nozzle virtually on top of the conveyor that could hit the product on the belt. Bete redesigned the hood by offering the customer a solution utilizing eight pieces of 3/8″ TW20-210 (210° spray). This configuration proved highly successful and this style of hood is now the blueprint for all the hoods in this area of the customer’s operation. The customer has even managed to increase the time between sanitation days and decrease the amount of time the lines are shut down. The new range of 3/8″ TW nozzles with 210° or 270° are perfect for situations in which a static, large free passage, tank wash nozzle that easily fit through small openings is needed.

Engineer’s Note: At the time of this application, 210° was the widest spray angle offered in the TW nozzle series. Bete now also offers a TW nozzle with a spray angle up to 270°.’

Custom Spray Nozzle Solutions – High Impact Spiral Tank Washing Nozzle Drawings and Sketches:

.jpg)