Equipped with Self-Lubricating Internal Sleeve Bearings for Maintenance-Free Performance

________________________________________________________________________________________________________________________

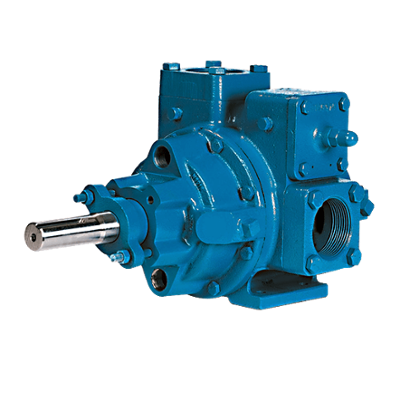

Specifically designed to offer maximum versatility for handling a wide variety of clean non-corrosive liquids, NP Series Sliding Vane Pumps, which are part of the Iron Line, are a general purpose positive displacement pump ideal for applications where high temperature, high pressure, high viscosity and/or shaft sealing requirements dictate a sleeve bearing pump are used. The key to the NP Series' versatility is the Blackmer® unique sliding vane rotor design that provides sustained, high level performance over a wide viscosity range. Slow operating speeds and non-pulsating flow minimizes shear and agitation of the fluid.

The unique head and bearing design of the NP Series pumps is conducive to a long bearing life - this design allows a small quantity of fluid to flow from the discharge side of the pump to the bearings. The small, continuous flow of fluid over the bearing surfaces provides a hydrodynamic film, minimizing temperature rise. These pumps are self-priming and dry run capable due to self-adjusting vanes. The NP pumps can run dry for short periods of time, ideal for priming and line stripping. Additionally, high volumetric efficiency and symmetrical bearing support mean the NP Series pumps require less horsepower than other PD pumps, which increases efficiency and cost savings to operate the pumps.

Blackmer fully Integrated Unit Assemblies are the pre-engineered and pre-designed drop-in pumping solution. These unit assemblies, include motor, gearbox, baseplate, coupling safety covers, and a NP Stainless Steel Sliding Vane Pump. No alignment required with these pre-configured fully Integrated Unit Assemblies as they are ready for immediate drop-in installation.

Features and Benefits

- Ductile-iron construction with metallized carbon sleeve bearings and non-metallic vanes for longer life

- Optional commercial mechanical seal with stainless steel, carbon, and PTFE construction

- Shaft stuffing box accommodates most standard aftermarket mechanical seal configurations

- Jacketed pump head option for high temperature operation

- Pump design and operation minimizes shear and agitation

- Adjustable relief valve protects pump against excessive pressures

Advantages of sliding vane technology:

- Unique sliding-vane pump design self-adjusts for wear to maintain flow rates

- Excellent self-priming and dry-run capabilities

- Sliding vane design provides sustained performance and trouble-free operation

- Easy maintenance: vanes can be easily replaced without removing the pump from the piping system

- High suction lift and line-stripping capabilities

- Low maintenance and low life-cycle costs

Applications

- Refiled fuels

- Greases

- Solvents

- Chocolate

- Syrups

- Molasses

- Edible oils

- Black liquor

- Sodium silicate

- Tallow

- Wax

- Glues

- Adhesives

- Creosote

- Asphalt

- Aqueous Film Forming Foam (AFFF)

________________________________________________________________________________________________________________________

Performance and Specifications

AVAILABLE MODELS |

NOMINAL FLOW RATE RANGE |

DIFFERENTIAL PRESSURE |

|

|

|

MAXIMUM WORKING PRESSURE (MAWP) |

TEMPERATURE |

VISCOSITY |

|

|

|

MIN/MAX SPEED (RPM) |

PRIMARY MATERIALS OF CONSTRUCTION |

CONNECTION ORIENTATION |

|

|

|

VANE MATERIALS |

CATALOG OPTIONS |

AVAILABLE CERTIFICATES |

|

|

|

Dimensions

| PUMP MODEL | L | W | H | APPROX. WT. | |

|---|---|---|---|---|---|

| NP1.5 | in | 15-3/4 | 10-9/16 | 8-1/2 | 47 lb |

| mm | 400.1 | 286.3 | 215.9 | 21 kg | |

| NP2 | in | 16-1/2 | 8-3/4 | 8-11/16 | 65 lb |

| mm | 419.2 | 247.6 | 220.6 | 30 kg | |

| NP2.5 | in | 19-1/8 | 10-11/16 | 9-5/8 | 92 lb |

| mm | 463.6 | 271.4 | 244.5 | 42 kg | |

| NP3 | in | 19-1/8 | 13-7/16 | 12-1/4 | 134 lb |

| mm | 485.9 | 341.3 | 311.2 | 61 kg | |

| NP4 | in. | 26 1/8 | 16 15/16 | 15 1/2 | 314 lbs. |

| mm | 663.6 | 430.2 | 393.7 | 142 kg | |

| NPH2 | in | 16-7/16 | 10 | 8-7/8 | 64 lb |

| mm | 417.6 | 254 | 225.4 | 29 kg | |

| NPH2.5 | in | 19 | 11-1/16 | 9-13/16 | 92 lb |

| mm | 482.6 | 281 | 249.2 | 42 kg | |

| NPH3 | in | 19-1/16 | 14-1/4 | 12-1/16 | 131 lb |

| mm | 484.2 | 362 | 306.4 | 60 kg | |

| NPH4 | in | 26-1/8 | 17-7/8 | 15-1/2 | 296 lb |

| mm | 663.6 | 454 | 393.7 | 134 kg |

Materials of Construction

| PRESSURE PARTS | PUMP MODELS | MATERIAL |

|---|---|---|

| Cylinder | NP1.5" – 3" | Cast Iron: ASTM A48 |

| NP4" & NPH2"-4" | Ductile Iron: ASTM 536 | |

| Heads | NP1.5" | Cast Iron: ASTM A48 |

| NP(H)2"-4" | Ductile Iron: ASTM 536 | |

| Packing Follower | NP1.5" | Cast Iron: ASTM A48 |

| NP(H)2" - 4" | Ductile Iron: ASTM 536 | |

| Bearing Covers | NP1.5" | Cast Iron: ASTM A48 |

| NP(H)2" - 4" | Steel | |

| Relief Valve | NP(H)1.5" - 3" | Cast Iron: ASTM A48 |

| Cover | NP(H)4" | Ductile Iron: ASTM 536 |

Pump Options

| OPTIONS | DETAILS |

|---|---|

| ORIENTATION OPTIONS | Right Hand: INLET is to the right, when looking from driven side Left Hand: INLET is to the left, when looking from driven side |

| PORTING OPTIONS | NP Series: Top Outlet: Outlet 90° offset from inlet NPH Series: Side Outlet: Outlet 180° offset from inlet |

| CONNECTION OPTIONS | NPT (threaded) Welded, ANSI Flange (Cl 150 RF) |

| MOUNTING OPTIONS | Pump Only Unit: Pump, Gearbox, Motor, Baseplate, Couplings, Guards |

| SEALING OPTIONS | PTFE Packing, Component Lip Cartridge Single Mechanical, Cartridge Triple Lip |

Vane Options

| MATERIAL | TEMPERATURE LIMITS | VISCOSITY |

|---|---|---|

| Duravane | -25°F to 240°F (-32°C to 115°C) | 0.2 - 4,250 cP |

| EC Laminate | -25°F to 350°F (-32°C to 177°C) | 0.2 - 8,500 cP |

| Bronze | -25°F to 500°F (-32°C to 260°C) | 105 - 22,000 cP |

| Cast Iron | -25°F to 500°F (-32°C to 260°C) | 105 - 22,000 cP |

Elastomer Options

| MATERIAL | TEMPERATURE LIMITS |

|---|---|

| FKM | -15°F to 400°F (-26°C to 204°C) |

| PTFE – SS Spring | 0°F to 500°F (-18°C to 260°C) |

| Buna-N | -25°F to 240°F (-32°C to 115°C) |

Maintenance Kits

| MODEL(S) | DESCRIPTION | PART NUMBER | ||

|---|---|---|---|---|

| NP1.5 | Kit - Maintenance | 898928 | ||

| NP2, NPH2 | Kit - Maintenance | 898929 | ||

| NP2.5, NPH2.5 | Kit - Maintenance | 898930 | ||

| NP3, NPH3 | Kit - Maintenance | 898931 | ||

| NP4, NPH4 | Kit - Maintenance | 898932 | ||