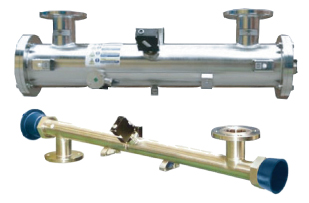

Aquionics UV Treatment Disinfection Systems are available in a large range of low pressure/amalgam and medium pressures. Whether you need to treat a small flow of high purity water for a pharmaceutical plant, or a huge flow of ballast sea-water on a ship, there is an system to suit your requirements.

Selecting the correct system for your needs is absolutely critical. We recommend that you contact us for further information on how to select and correctly size a UV system, or for a detailed quote.

Aquionics PureLine Range of Products

Aquionics PureLine UV disinfection range is specifically designed to provide chemical-free disinfection of water, syrups, and brines, in the food, beverage, and brewing industries. The PureLine range includes standard models for virtually any food and beverage processing application, including deozonation, de-chlorination, TOC reduction, as well as validated, performance qualified models (PQ) for the most stringent disinfection applications. The PureLine range allows for easy installation, requiring little disruption to the plant. Maintenance is simple and can be carried out by on-site personnel. UV is a non-chemical method of treatment, so there is no possibility of a detrimental effect on product stability and products are also free from unwanted residues, colors, and odors.

Aquionics PureLine UV systems:

- Provide chemical-free disinfection

- Remove chlorine and ozone

- Are clean and safe, with no side effects or residue

- Offer validated performance

- Are compact and easy to install

- Are simple and inexpensive to maintain

- Are backed by Aquionics’s global support network

Aquionics PureLine DAquionics PureLine D (Disinfection) UV System is specifically designed to provide chemical-free disinfection in a variety of industries and markets. The PureLine range allows for easy installation, requiring little disruption to the plant. Maintenance is simple and can be carried out by on-site personnel. UV is a non-chemical method of treatment, so there is no possibility of a detrimental effect on product stability and products are also free from unwanted residues, colors, and odors.

|

|

Aquionics PureLine BAquionics PureLine brine disinfection range of UV systems, eliminate water-borne pathogens that put food producers at high risk of costly and damaging product recalls. A properly sized UV system can be guaranteed to inactivate Listeria monocytogenes, lactic acid bacteria, and other harmful contaminants, making UV disinfection a very important function for meat processing. Aquionics PureLine B systems fit into existing pipework relatively easily, requiring minimum disruption and site preparation. Maintenance is simple and can be carried out by on-site personnel. Systems are available in both Low Pressure High Output Amalgam lamps and Medium Pressure lamp technology.

|

|

Aquionics PureLine DCAquionics PureLine deozonation range of UV systems provide water to the highest possible standards as demanded by regulatory agencies. A properly sized UV system can be guaranteed to destroy ozone to non-detectable limits. Utilizing powerful, low wavelength ultraviolet light the PureLine DC Series will provide you the assurance that your product and processes are protected. The PureLine range allows for easy maintenance, requiring little disruption to the plant. Maintenance is simple and can be carried out by on-site personnel. Systems are available in both Low Pressure High Output Amalgam lamps and Medium Pressure lamp technology.

|

|

Aquionics PureLine SAquionics PureLine sugar syrup disinfection range of UV systems inactivate both active and dormant microorganisms found in liquid sweeteners. Sucrose-based sweeteners can be a prime breeding ground for microorganisms. The PureLine S was specifically designed to handle the rigors of sugar syrup disinfection. A properly sized UV system can be guaranteed to inactivate bacteria found in both the sugar syrup and dilution water. The PureLine S systems fit into existing pipework relatively easily, requiring minimum disruption and site preparation. Maintenance is simple and can be carried out by on-site personnel. Systems are available in Medium Pressure lamp technology.

|

|

|

|

|

Aquionics PharmaLine UV systems:Chemical free disinfection in the pharmaceutical, healthcare and cosmetics industries.

|

|

Aquionics PharmaLine DLGeneral Disinfection System: Loop process water. High efficiency and low energy UV systems for general disinfection of Pharmaceutical distribution loop process water. Don’t give microorganisms a chance…kill them all, every timeWhen patients’ health depends on you, you can depend on Aquionics UV who ha spent over eight decades working closely with medical device suppliers, ophthalmic manufacturers, hospitals and research centers. Meeting, and exceeding, their disinfection needs. We integrate seamlessly and easily into your existing production lines. We disinfect the water you use everywhere in your process. And, unlike some technologies, we produce no nasty wastes. It’s a simple indication of how useful, and effective, our UV systems actually are. Sterile, safe, simpleIf you’d like to provide sterility for your products, and purity for your process water, Aquionics UV is the right choice. No other technologies purify everything from raw materials through production lines to packaging – and that do it so very well.

The solution pharma demandsWith this much flexibility, it’s no surprise that our UV systems sterilize everything from production lines and packaging facilities to water intakes and header tanks.

|

|

Aquionics PharmaLine DODe-ozonation system: UV systems for Ozone destruction in Pharmaceutical process water. Ozone is used in many water treatment applications from swimming pools to Ultrapure Water for pharmaceutical or microelectronics production. Whilst being and effective disinfectant, ozone has characteristics which can lead to problems: – Ozone itself is highly toxic and dangerous to handle Aquionics UV systems utilise powerful, low wavelength, ultraviolet light to destroy bacteria and other microorganisms without the use of chemicals. This make your process simpler, extends the life of your RO or EDI membranes. In addition, Aquionics UV systems are easy to install, have very simple maintenance requirements, and therefore low running costs Pharmaceutical and healthcare products require production facilities of the utmost quality. Water used for product, and for CIP must be free of pathogens, and chemicals such as chlorine and ozone. Aquionics UV systems help provide water to the highest possible standards as demanded by regulatory bodies such as FDA quality procedures including Good Manufacturing Practice (GMP). Aquionics UV systems:

The solution pharma demandsAquionics UV systems sterilise everything from production lines and packaging facilities to water intakes and header tanks.

|

|

Aquionics PharmaLine DPGeneral Disinfection System: Pre-treatment process High efficiency and low energy UV systems for general disinfection of Pharmaceutical and Pre-treatment process. Placement of the UV system ahead of the carbon filters for dechlorination provides higher carbon filter efficiency resulting in longer carbon runs, thus decreasing your operating costs. In addition to extending the life of carbon beds, dechlorinating process water will remove the off flavours associated with chlorine disinfection. The flavour of the final product will remain unadulterated and free from undesirable flavours and odours. Don’t give microorganisms a chance…kill them all, every timeWhen patients’ health depends on you, you can depend on Aquionics UV who ha spent over eight decades working closely with medical device suppliers, ophthalmic manufacturers, hospitals and research centers. Meeting, and exceeding, their disinfection needs. We integrate seamlessly and easily into your existing production lines. We disinfect the water you use everywhere in your process. And, unlike some technologies, we produce no nasty wastes. It’s a simple indication of how useful, and effective, our UV systems actually are. Sterile, safe, simpleIf you’d like to provide sterility for your products, and purity for your process water, Aquionics UV is the right choice. No other technologies purify everything from raw materials through production lines to packaging – and that do it so very well.

The solution pharma demandsWith this much flexibility, it’s no surprise that our UV systems sterilize everything from production lines and packaging facilities to water intakes and header tanks.

|

|