Rotary Jet Mixers

Designed for use in the brewery and beverage, dairy, personal care and biopharm industries, Rotary Jet Mixers effectively handle liquid mixing, gas dispersion, powder mixing, and tank cleaning while reducing mixing time, energy consumption and costs.

Range Includes:

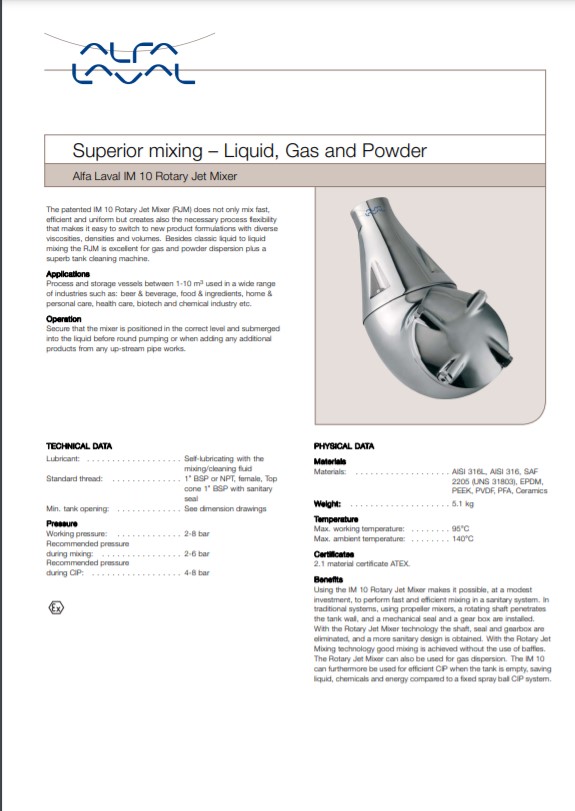

- Alfa Laval IM 10 Rotary Jet Mixer

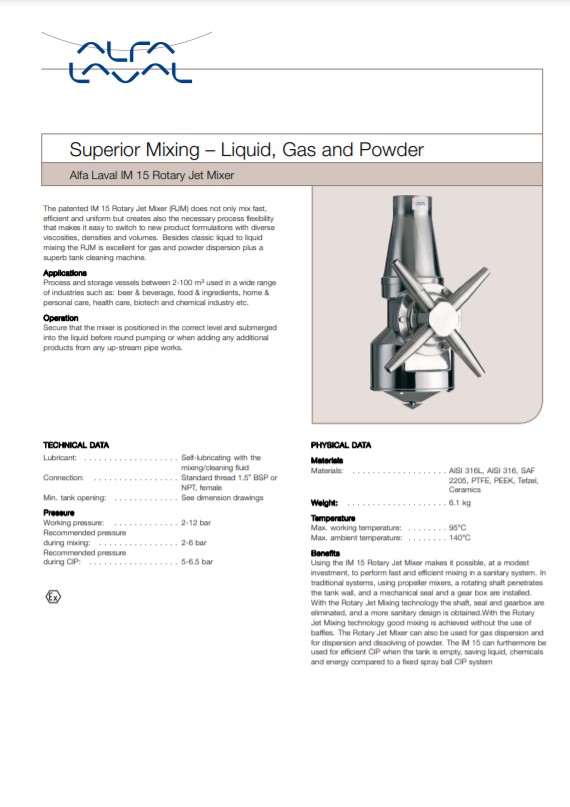

- Alfa Laval IM 15 Rotary Jet Mixer

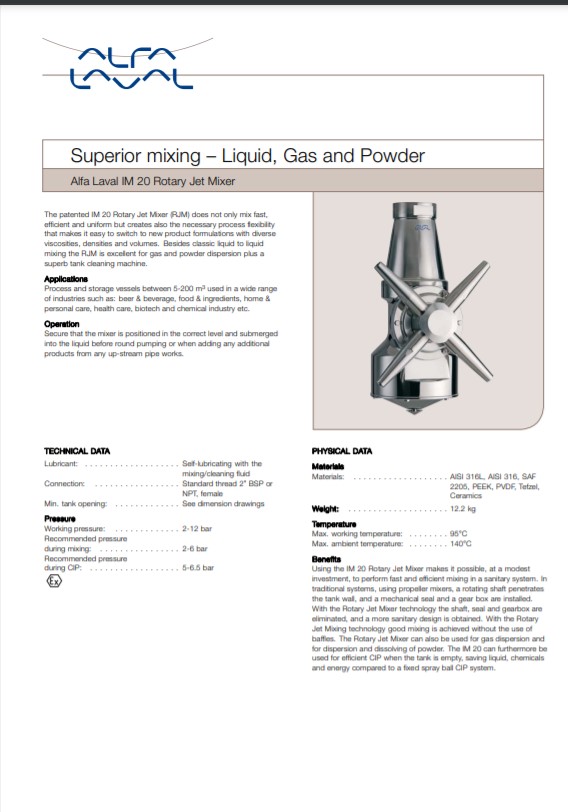

- Alfa Laval IM 20 Rotary Jet Mixer

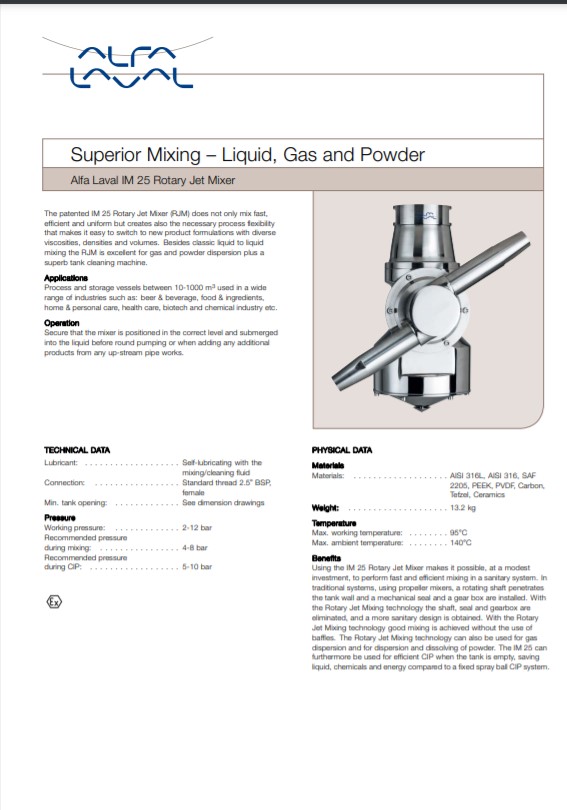

- Alfa Laval IM 25 Rotary Jet Mixer

Unmatched Mixing Performance

In many applications Rotary Jet Mixers provides the fastest and most efficient mixing results. It also handles gas dispersion (aeration, deaeration, carbonation), powder mixing and cleaning in place (CIP). Its patented rotary jet mixing technology is based on rotary jet head technology, which has been modified to handle mixing of liquids, gas and powder. Rotary jet mixers can be used in tanks between 100 and 800,000 liters in size.

Faster and More Effective Mixing

When using Rotary Jet Mixers the capacity can be increased, resulting in greater productivity, higher product quality and improved utilization of process plant resources.

Handles Multiple Applications

Rotary Jet Mixers help reduce capital expenditures and operating expenses while achieving fast and efficient mixing. A single Rotary Jet Mixer can handle liquid mixing, gas dispersion and powder dispersion applications – plus tank cleaning – without requiring separate equipment for each process and thereby delivering significant savings.

Simplified Design

The system offers savings in tank and supporting structure because the motor and pump can be placed on the floor. And at the same time the Rotary Jet Mixer being placed under the liquid surface is a hydraulically balanced system which does not create any significant loads on the tank. In addition to this its easy-to-install design facilitates retrofitting of existing tanks.

Skid Mounted Pump Units Available

A number of pre-engineered Skid Mounted Pump Units are available to complement the Rotary Jet Mixers. In addition to a Rotary Jet Mixer, the end-users also require a pump and instrumentation for their mixing system. To make it easy for them a number of pre-engineered unit with all the necessary equipment have been designed. For end-users this will save time and resources as they can bypass engineering and procurement. All they have to do is connect two pipes, do the electrical wiring, set up the variable frequency drive – and they are ready to go.